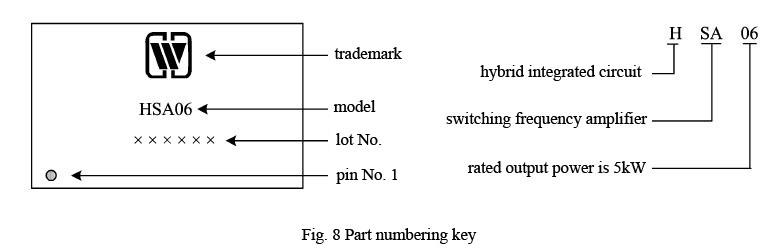

1.Features(for outside view, see Fig. 1)

|

It can be used interchangeably with SA06 of APEX company. |

|

|

10A continuous output current (Case temperature ≤75℃) |

|

|

Thermal protection and programmable external current-limiting protection |

|

|

Analog and digital input |

|

|

Synchronous or external oscilloscope |

|

|

Flexible frequency control |

and

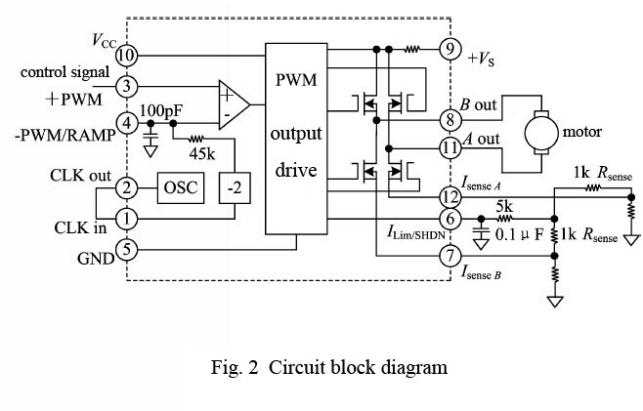

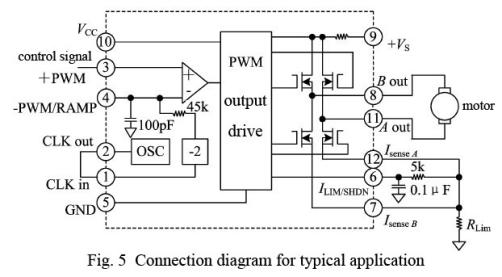

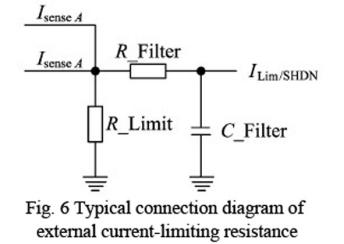

and  , when adopting voltage mode control, these two terminals shall be short-circuited, the typical connection diagram is shown as in Fig. 5; while adopting current control, they shall be connected to sampling resistance and the sampling resistance shall choose non-inductive resistance, the typical connection diagram is shown as in Fig. 2.

, when adopting voltage mode control, these two terminals shall be short-circuited, the typical connection diagram is shown as in Fig. 5; while adopting current control, they shall be connected to sampling resistance and the sampling resistance shall choose non-inductive resistance, the typical connection diagram is shown as in Fig. 2.

is the set current-limiting value, at the beginning, set R-Filter and C-Filter to 5kΩ and 0.01µF, respectively.

is the set current-limiting value, at the beginning, set R-Filter and C-Filter to 5kΩ and 0.01µF, respectively.

|

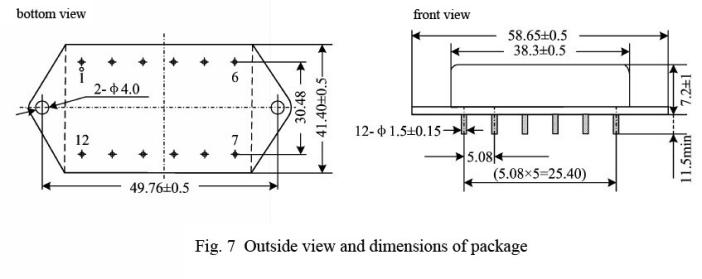

Case model |

Header |

Header plating |

Cover |

Covering plating |

Pinmaterial |

Pin plating |

Sealing style |

Notes |

|

UPP4138 -12a |

Cold rolled steel (10#) |

Ni |

Iron/ nickel alloy (4J42) |

Ni |

Coppercompound |

Ni |

Compression seal |

|

X

X