Hydrogen purification equipment manufacturer

Water Electrolysis Hydrogen Production Equipment/Hydrogen Purification Equipment

Zhongxinda medium pressure hydrogen purification equipment.

It is equipped with a variety of processes such as hydrogen generated and air separation nitrogen regeneration and three-tower regeneration without consuming raw gas.

Hydrogen with high purity is obtained after catalytic deoxygenation, cooling and condensation,

adsorption secondary drying and high efficiency filtration of sintered nickel tube. The equipment is widely used in electronics, gold, chemical, glass, new energy and other industries.

|

ZXD Hydrogen Purification Plant |

||||

|

P/N &Specification |

ZXD50 |

ZXD100 |

ZXD200 |

|

|

Treatment capacity m3/h |

50 |

100 |

200 |

|

|

Working Pressure MPa |

0.8-1.6 |

0.8-1.6 |

0.8-1.6 |

|

|

Working Temperature |

Deoxidation℃ |

80-100 |

80-100 |

80-100 |

|

Dry℃ |

10 |

10 |

10 |

|

|

Regenerate℃ |

250 |

250 |

250 |

|

|

Cooling Water Volume t/h |

1.5 |

3 |

4 |

|

|

Power Consumption KW |

4 |

6 |

9 |

|

|

Instrument Gas Consumption m3/h |

2 |

3 |

3 |

|

|

Product gas |

Moisture content (dew point) |

≤-75℃ |

≤-75℃ |

≤-75℃ |

|

Oxygen Content(ppm) |

≤2 |

≤2 |

≤2 |

|

|

Control Mode |

PLC Fully Automatic |

PLC Fully Automatic |

PLC Fully Automatic |

|

|

External dimension |

2×1.5×2.5 |

2.8×1.8×2.8 |

3.2×1.8×2.8 |

|

|

Length × Width × Height (m) |

||||

|

Unit Weight(t) |

2 |

3 |

3.5 |

|

|

How to maintain hydrogen production equipment? |

FAQS |

What is the standard of hydrogen production equipment? |

|

In which sectors is hydrogen used in particular? |

||

|

Is hydrogen only a temporary solution? |

||

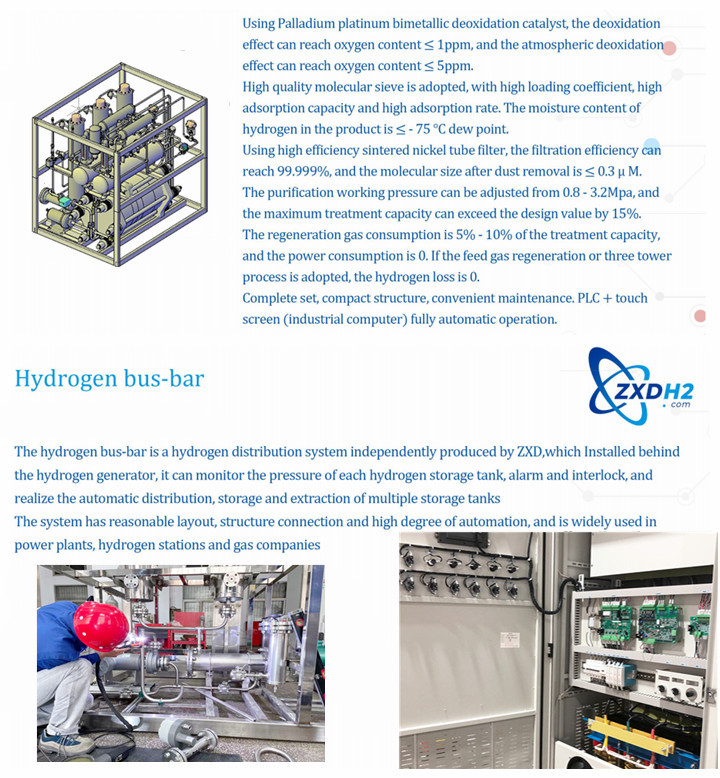

Technical Characteristics

一 The Special activation treatment is carried out on thecathode of the electrolyzer to ensure the high waterelectrolysis efficiency with low power consumption andsave electric energy for customers ;

一 An electrolyzer is composed of a plurality of stage plateshe voltage of each electrolyzer is adjustable from 1.8 to2.2 , and the DC voltage is adjustable from 30V to 58Vaccording to the rated voltage of electrolytic : ( subject tohydrogen production data of electrolyzer ) maximum DCurrent 820A ( detailed parameters confirmed withhydrogen production during engineering design

一 The chemical KOH ( concentration 25-30 % ) is used as anadditive in electrolytes to increase the conductivity , but itdoes not consume chemicals during normal operation , soit does not need to be supplemented in the electrolyteafter the first start-up .

X

X