Tech. specification of H2 generation unit

No.

Item/Description

Unit

Specification

1

H2 rated flows

Nm3/hr

1000 (1 atm, 0oC)

2

O2 rated flows

Nm3/hr

500 (1 atm, 0oC)

3

Operating pressure

Mpa

1.5

4

H2 purity

%

≥99.99

5

O2 purity

%

≥99.8

6

Operating temperature

℃

85±5

7

Average cell voltage

V

≤ 2

8

Operating DC current

A

13400

9

Moisture content in H2

g/m3H2

≤ 4

10

Lye content in H2

mg/ m3H2

≤ 1

11

DC power consumption

KWh/ m3H2

≤4.6 (electrolyzer)

12

Control mode

PLC Siemens, HMI monitoring; Alarm, record, Trench, etc.

Technical features of hydrogen generation system

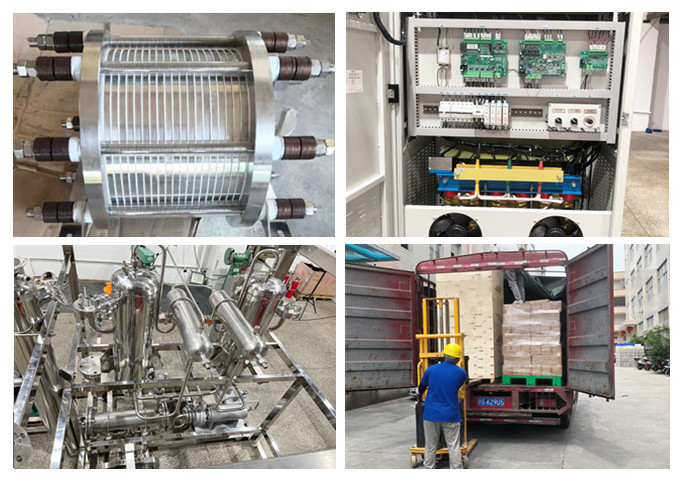

Detailed Images

Transportation and Application

These include:

Certification

X

X