The machine is designed to produce high quality paper drinking straw with high production capacity,full automatic running.

New 8 Cutting Knife Paper Drinking Straw Making Machine

How it works?

Winding/spiraling different layers of the paper strip into the paper tube with glue.

Multi-cutting knife system, by servo track, cut the paper tube into a small piece of paper drinking straws.

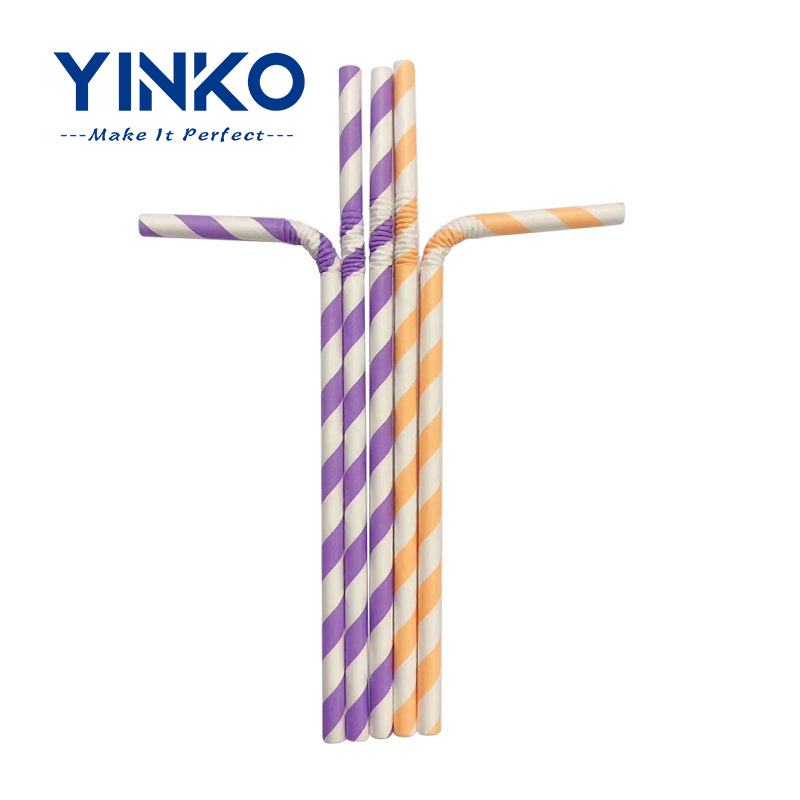

Material: food-grade white craft paper and food-grade glue.

Sub-raw material: may need oil for lubrication and cooling. White mineral oil.

|

|

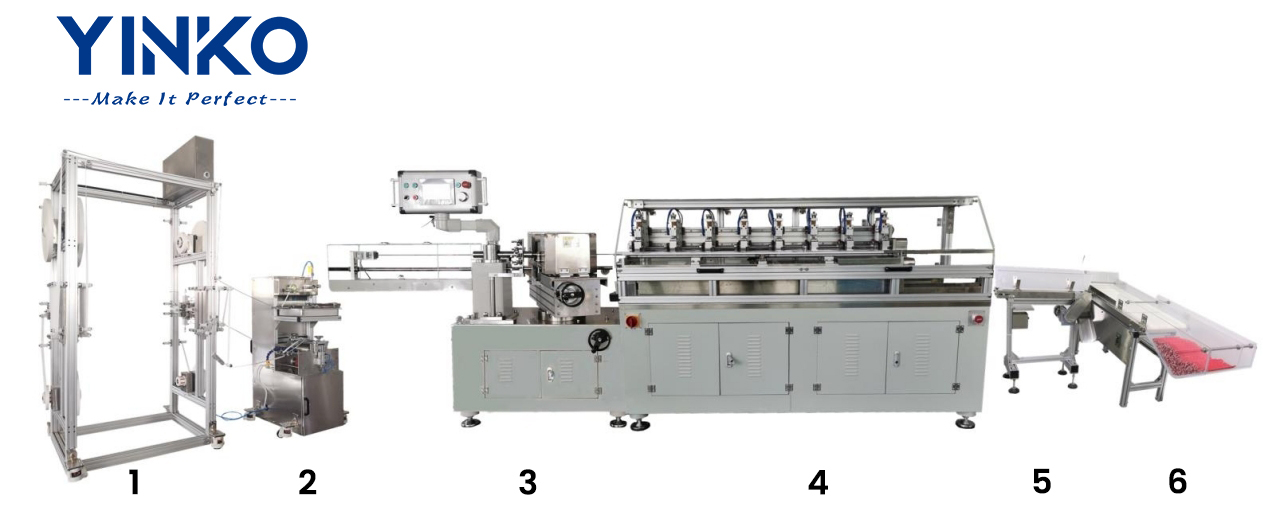

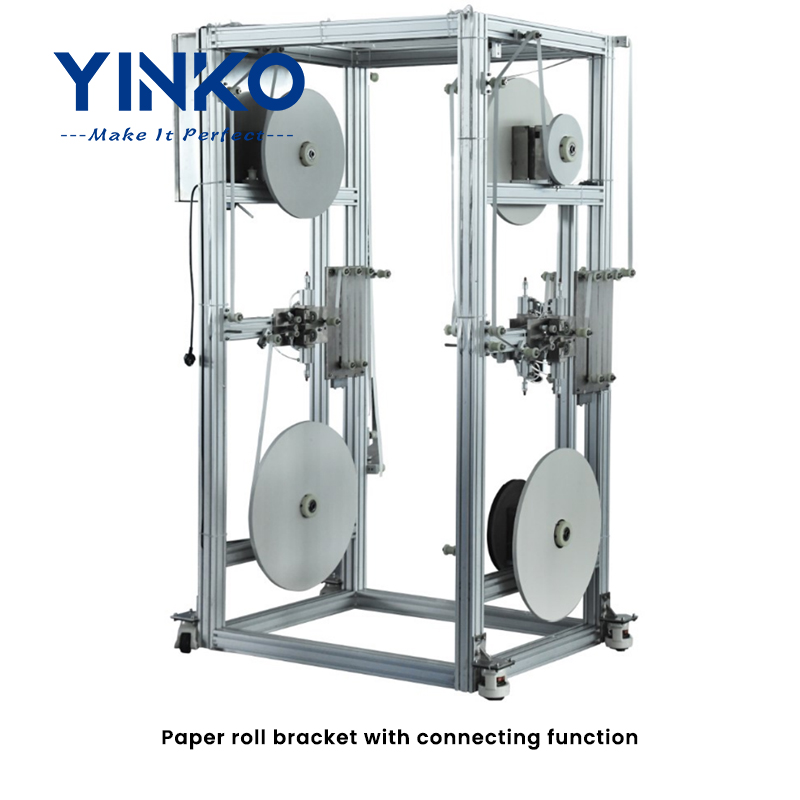

The whole system consists of following parts:

|

Features

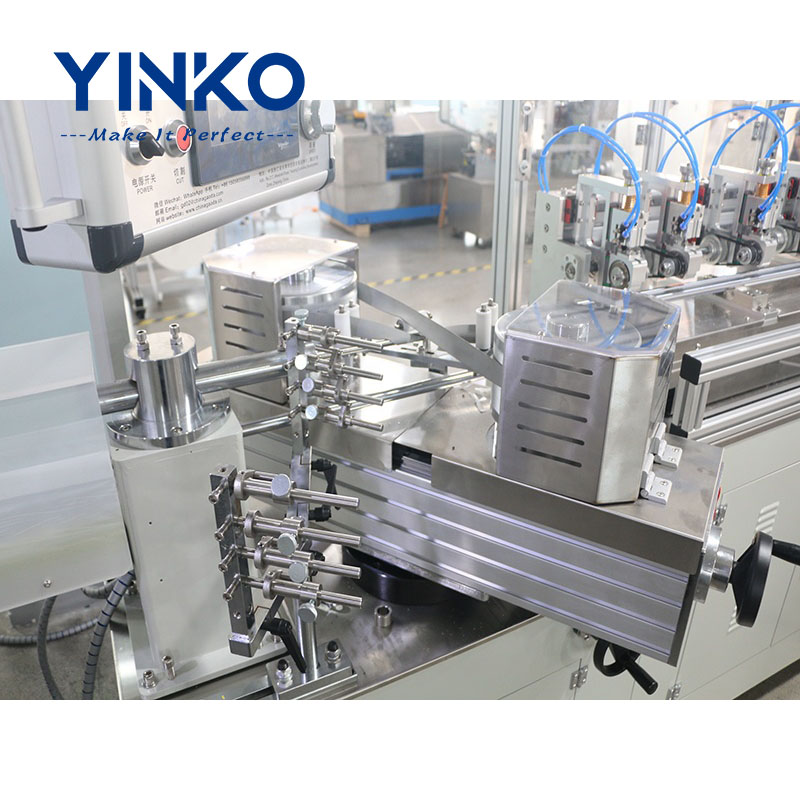

Machine details

|

|

|

|

|

Specifications

| Model | YKZXG-20 |

| Electric power | 3P 380V 50HZ |

| Power consumption | 4.5~6.5KW/H |

| Full load amps | 13.5A |

| Production speed | 0~80m/min(output) |

| 0~105m/min(paper feeding) | |

| Paper layer | 2-4 layers |

| Straw diameter | 4.3~12mm(outer diameter) |

| 3.5~11.3mm(inner diameter) | |

| Max thickness | 0.6mm-single side |

| Min thickness | 0.2mm-single side |

| Straw length | 100~1400mm(distance between 2 blades) |

| Cutting method | 8 knifes,pneumatic driving |

| Glue method | single & double side |

| Length control | Encoder |

| Speed control | Servo tracking |

| Mandrel fixing | Screw clamp |

| Synchronism control | Servo belt |

| Winding belt tension control | Hand wheel |

| Belt angle control | Hand wheel |

| Lubrication | lubrication grease |

| Main parts dimension | 3850×1200×1600mm |

| Land area required | 8000x4500x1900mm |

| Winding roller diameter | 215mm |

| Winding roller height | 120mm |

| Weight | 1400kg |

| Main parts | |

| PLC | Pankong |

| Control screen | Schneider |

| Control system | GD-XJ2.0 |

| Servo motor | Schneider |

| Frequency converter | |

| Circuit breaker | |

| Relay | |

| Signal sensor | Omron |

| Encoder | Omron |

| Pneumatic cylinder | AIRTAC |

| Bearing | HRB |

Paper straw photos

|

|

|

One stop solutions

We can provide more~

|

|

|

|

| Automatic paper straw bevel cutting machine | Flexible paper straw bending machine | ||

| Do you want more information? contact us right now | |||

FAQ

|

1. How to calculate the output capacity of paper straw per miniute? Answer: For example, 70m/min, making 6*197mm straws. Considering some waste, we use 200mm(straw length) for calculating.70m*1000/200mm=350 pcs/minute. |

|

2. What information shall we provide if we want to get a quote from your company? Answer: different straw diameter need different straw mold, you need to tell us the straw diameter that you want to produce,also the layer of paper straw,the most common is 3 layers paper straw, for 10mm-12mm paper straws,better to make 4 layers, the cost will also increased. |

|

3. Do you provide free spare parts? Answer: Yes, we provide cutting blades,winding belt,straw mold,air cyclinder |

|

4. Do you have paper straw bending machine, straw packing machine? Answer: Yes,we provide complete solutions, from straw making to straw packing machine. |

|

5. What about training & installation? Answer: We can provide on site training in our factory, it's better if your company can send one engineer come and get training here. |

|

6. What about lead time and payment? Answer: 40days, 30% deposit by TT,balance paid before delivery. |

X

X