The machine is designed to produce high quality paper drinking straw with high production capacity,full automatic running.

New 9 Cutting Knifes Paper Drinking Straw Making Machine

Winding/spiraling different layers of the paper strip into the paper tube with glue.

Multi-cutting knife system, by servo track, cut the paper tube into a small piece of paper drinking straws.

Material: food-grade white craft paper and food-grade glue.

Sub-raw material: may need oil for lubrication and cooling. White mineral oil.

|

|

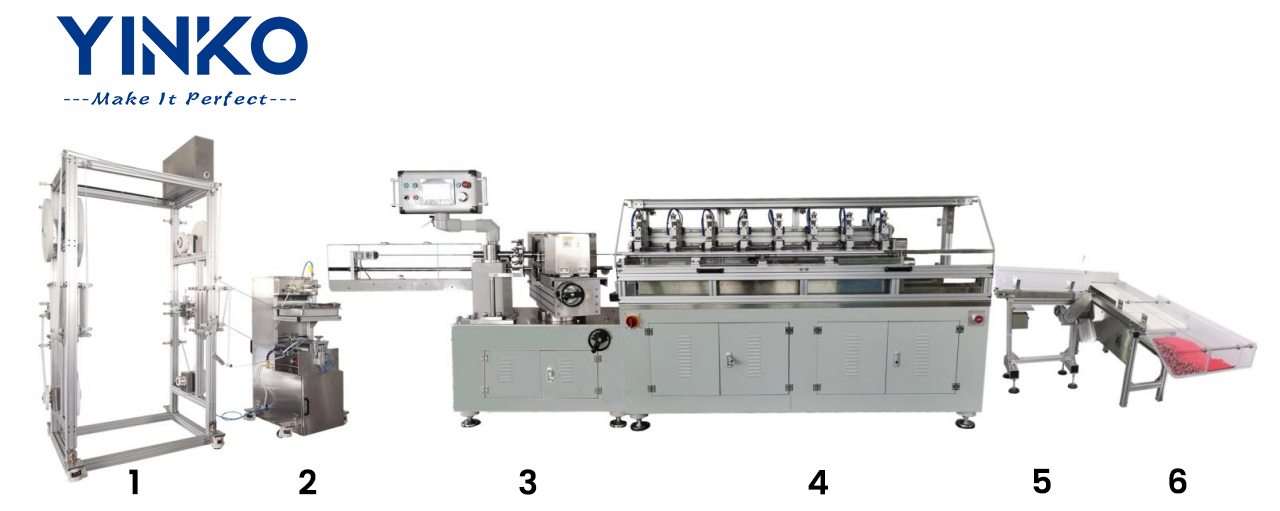

The whole system consists of following parts:

|

Features

Machine details

|

|

|

|

|

|

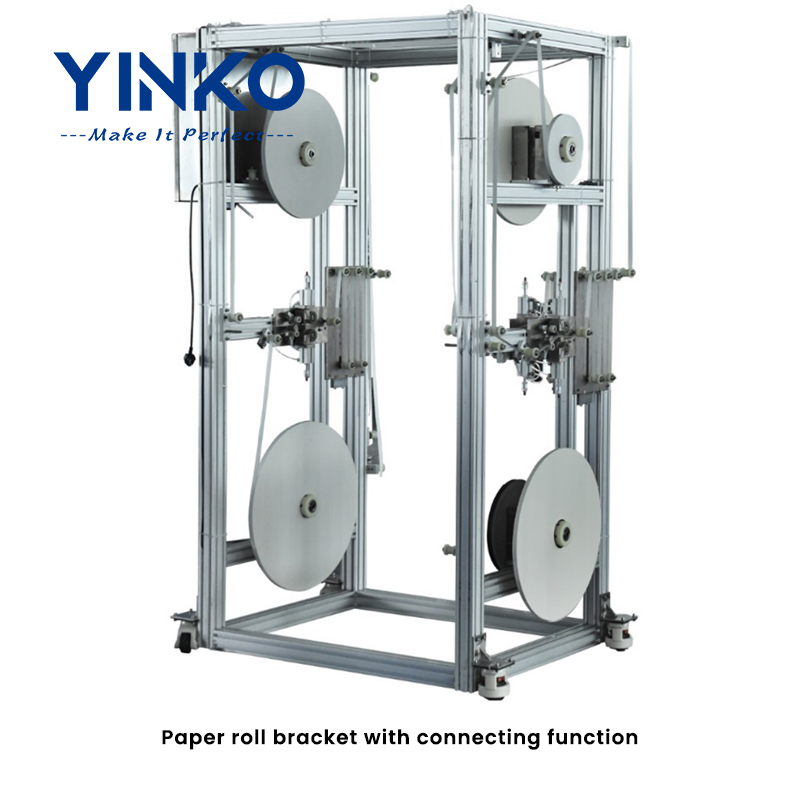

1.Help the paper straw-making machine not stop working. 2.Use auto-detection: When the paper roll is running out, the mechanism will cut the tail ends of the old paper roll and connect the new paper roll automatically. 3.Smaller dimension, easy delivery, and moving to adjust paper feeding angle. 4.Construction simpleness. If the paper break, no need to stop to route the paper up and down complicated. 5.Constant unwinding force for the paper rolls, to let paper feed more smoothly. 6.Optional choose: 4 layers connecting mechanism. |

Aluminum and stainless steel frame; Stainless steel glue pot; Glue recycle system Lubrication oil roller for inner paper strip; One pair roller ( rubber roller and steel roller) for filming glue on paper. 1 motor to drive glue roller; Easy to adjust glue quantity by adjust the distance of two roller. |

For more information,please feel free to contact us

Specifications

| Model | YKZXG-30 |

| Electric power | 3P 380V 50HZ |

| Power consumption | 4.5~6.5KW/H |

| Full load amps | 13.5A |

| Production speed | 0~95m/min(output) |

| 0~120m/min(paper feeding) | |

| Paper layer | 3-4 layers |

| Straw diameter | 4.3~12mm(outer diameter) |

| 3.5~11.3mm(inner diameter) | |

| Max thickness | 1mm-single side |

| Min thickness | 0.2mm-single side |

| Straw length |

90mm-1580mm(between 2 blades) |

| Output speed | 3-110m/min |

| Cutting method | 9 knifes,pneumatic driving |

| Glue method | single & double side |

| Length control | Encoder |

| Speed control | Servo tracking |

| Mandrel fixing | Screw clamp |

| Synchronism control | Servo belt |

| Winding belt tension control | Hand wheel |

| Belt angle control | Hand wheel |

| Lubrication | lubrication grease |

| Machine dimension |

4250×640×1600mm |

| Land area required | 9500x3500x1900mm |

| Winding roller diameter | 195mm |

| Winding roller height | 100mm |

| Weight | 1350kg |

| Main parts | |

| PLC | Schneider |

| Control screen | Schneider |

| Control system | GD-XJ3.0 |

| Servo motor | Schneider |

| Frequency converter | |

| Circuit breaker | |

| Relay | |

| Signal sensor | Omron |

| Encoder | Omron |

| Pneumatic cylinder | AIRTAC |

| Bearing | HRB |

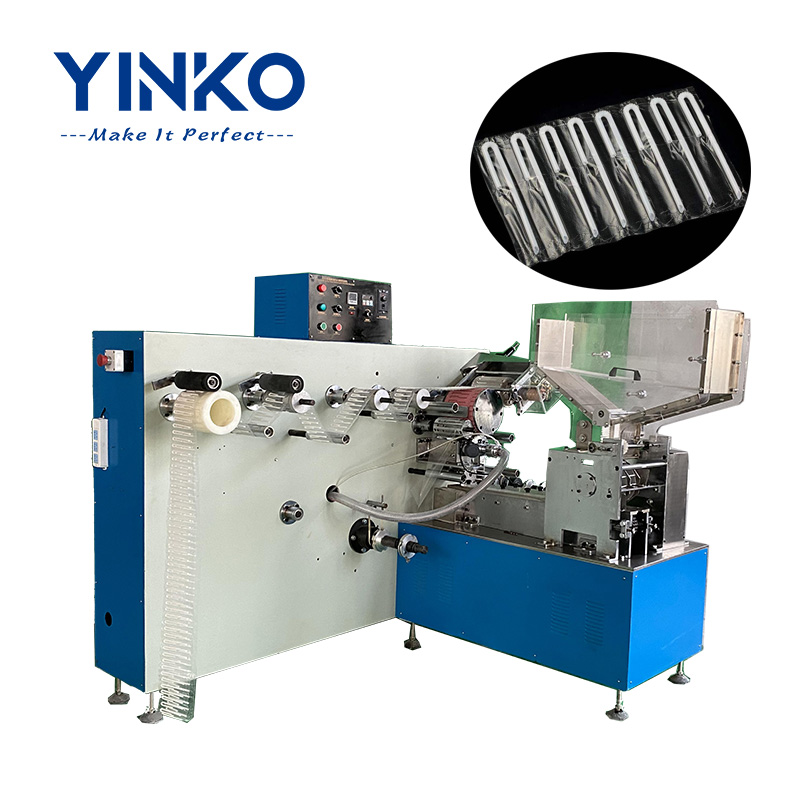

Paper straw photos

|

|

One stop solutions

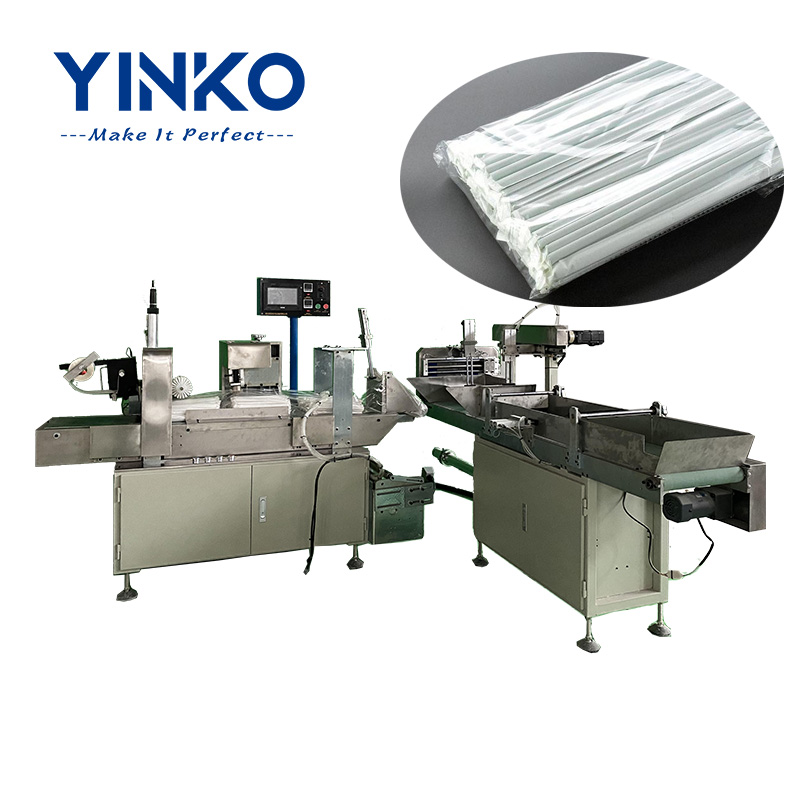

We provide complete production line from straight straw making to flexible straw bending,straw packing machine,

|

|

|

|

| Flexible straw bending machine | U shape straw packing machine | Individual straw packing machine | Group straw packing machine |

For more information,please feel free to contact us

FAQ

|

1. How to calculate the output capacity of paper straw per miniute? Answer: For example, 70m/min, making 6*197mm straws. Considering some waste, we use 200mm(straw length) for calculating.70m*1000/200mm=350 pcs/minute. |

|

2. What information shall we provide if we want to get a quote from your company? Answer: different straw diameter need different straw mold, you need to tell us the straw diameter that you want to produce,also the layer of paper straw,the most common is 3 layers paper straw, for 10mm-12mm paper straws,better to make 4 layers, the cost will also increased. |

|

3. Do you provide free spare parts? Answer: Yes, we provide cutting blades,winding belt,straw mold,air cyclinder |

|

4. Do you have paper straw bending machine, straw packing machine? Answer: Yes,we provide complete solutions, from straw making to straw packing machine. |

|

5. What about training & installation? Answer: We can provide on site training in our factory, it's better if your company can send one engineer come and get training here. |

|

6. What about lead time and payment? Answer: 40days, 30% deposit by TT,balance paid before delivery. |

X

X