Economical Coil Slitting Machine/Economical Coil Recoiling Machine/ Smart Slitting Line Machine

is used to let the steel coil to uncoiler, section shear and recoiler.

Economical Coil Slitting Machine/Economical Coil Recoiling Machine:

The coil change in to some smallar coils, which have the requirement length. This line is fit to machining galvanized steel and pre-painted steel.

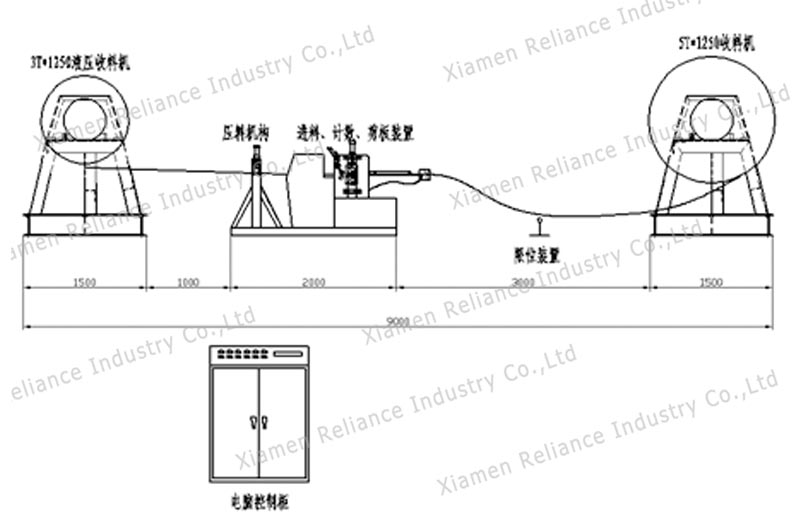

The production line including uncoiler, leveler, section shear, recoiler, unloading set, etc.

Whole line is controlled by PLC, human and machine screen display, high automatic degree, control simple and convenient operation.

Economical Recoiler Machine specification:

Material: Max. Coil Width 1250mm; Thickness Range: 0.3-0.8mm

Slitting accuracy≤0.5mm

Galvanized steel, Cold rolled steel, PPGI steel

Slitting/Recoiling speed: Approx. 15mpm

●5TonX1250 Hydraulic Un-coiler:

Hydraulic system expand coil inner hole, Pump motor: 3KW

Frequency Inverter to regulate turning speed, Motor: 3KW

Taper-wedge expanding system

Load capacity = Max.5Tons

Coil Inner-diameter=510±30 mm, Coil width = Max.1250mm

Automatic stopping device with limited switch as assistance to control stop/star rotation

●Feeding device Un-powered:

Manual feeding, un-powered

Two shafts before shearing machine with Pneumatic cylinder to keep the sheet straight

●Shearing machine:

PPGI and PPGL and Zinc-Aluminium coil

Main Power:1.5KW

Cut-to-length control

Comments: After shearing, the encoder still keeps the counting but the next sheet shall be guiding by manual to the re-coiler.

Pneumatic cylinder to press, for nice recoiling purpose, UN-powered

●3Ton*1250mm motorized re-coiler:

Power running, frequency speed control, manual speed control

Frequency Inverter to regulate turning speed, Motor: 3KW

Link-connect expanding system

Manual control to expand coil inner hole

Load capacity = Max.3Tons

Coil Inner-diameter=200±30 mm, Coil width = Max.1250mm

● PLC Control System:

Control the quantity & cutting length automatically.

Combined with: PLC, Touch Screen (Simens), Inverter (Schneider), Encoder (Omron), etc

Cut-to-length tolerance≤±2 mm

Control voltage 24V

COMMENTS: The Air compressor shall be provided by the customer only.

●Simple Recoiling Line Machine:

X

X