800pcs/min Full Servo Ultra Thin Sanitary Napkin Production Making Machine

|

Stable Working Speed |

600-1200pcs/min |

|

Pass Percentage |

≥98% |

|

Operating Rate |

≥85% |

|

Power Supply |

380V 50Hz |

|

Electrical Supply |

380V ±5%, 50Hz Three-phase four-wire + ground wire |

|

Power Installed |

About 180KW (Not included hot melt glue machine) |

|

Supply Pressure |

0.6-0.8Mpa |

|

Machine Sizes |

22.0m* 5.5m* 3.5m(L* W* H ) |

|

Main Engine Sizes (L× W× H ) |

32m* 9.0* 5.0m (L*W* H ) |

|

Machine Color |

Customerized |

1. Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film.

2. Tension system:

Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine.

3. Drive system:

Full servo driven, imported timing blet, key position adopt with the imported bearing.

4. Safety system:

It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer.

5. Materials corrective system:

Germany BST automatic web guide system(optional)

1. PE film and cloth-like film materials

2. PP/MAGIC Side/Frontal Tape

3. Hot-melted glue(Spandex/Structure)

4. FLUFF PULP(treated/untreated,SAP)

5. Jumbo tissue paper(Upper/Lower Tissue Papdsxer)

6. Non-Woven (Topsheet-Hydrophilic N.W./ leakage-Hydrophobic N.W.)

7. Spandex

8. Release tape for sanitary napkin

9. Released paper (winged/back of sanitary pad)

10. Sap absorbent paper

11. Outside PE bags/Polybags

12. Elastic waistband

13. ADL

About NISO

NISO is a professional raw materials and machine supplier for making baby diaper, adult diaper, feminine sanitary napkin,under pad and so on.

NISO covers an area of 5000 square meters, gets CE, ISO, SGS.

NISO exports more than1000 containers to Asia, Mid-east, Europe, South America, Africa countries.

NISO will be your consultancy and partner to reach win-win career together.

Quanzhou Niso Industry Co.,Ltd is your best choice for baby diaper machine, adult diaper machine, sanitary napkin machine and under pad machine in China.

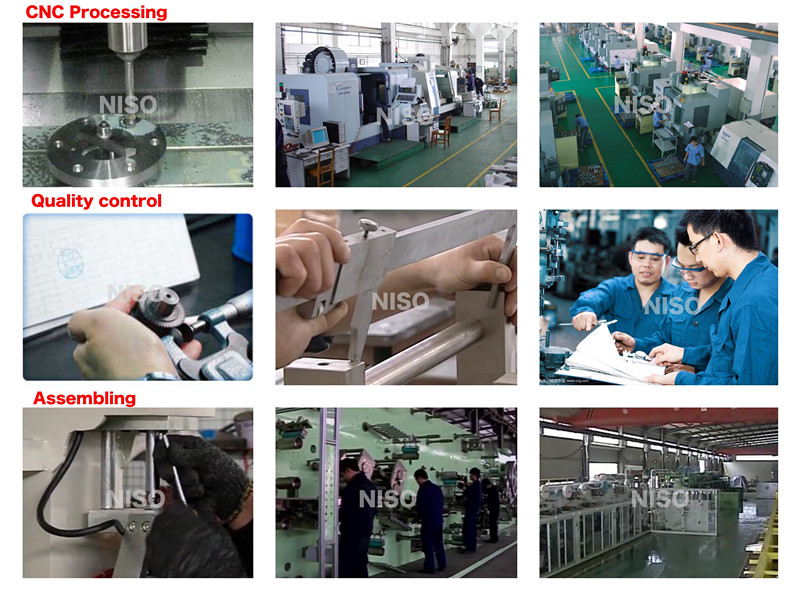

Factory Processing Map

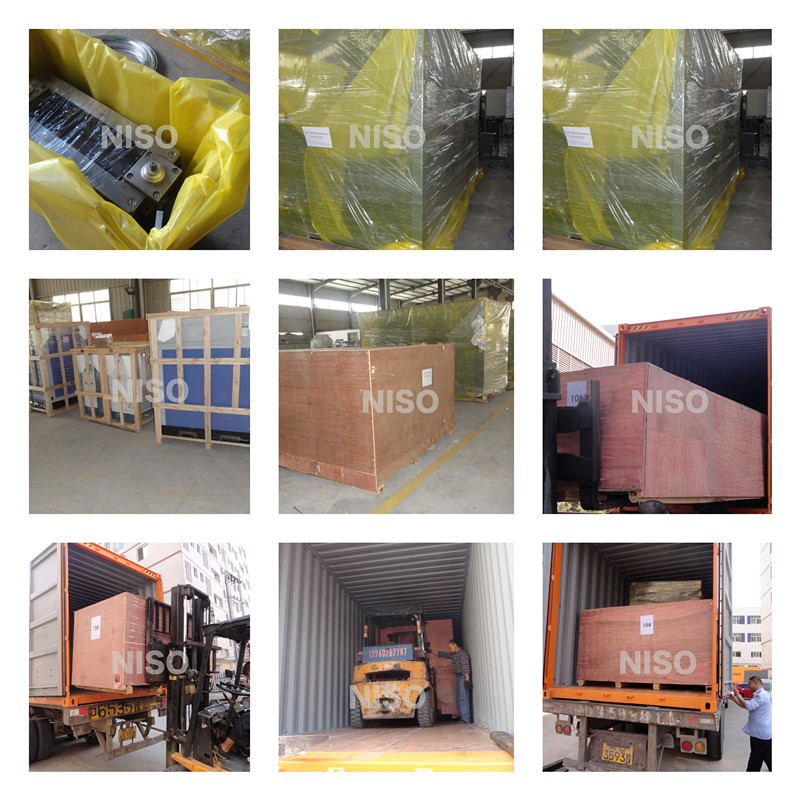

Packing and Packaging Diagram

Our Customers

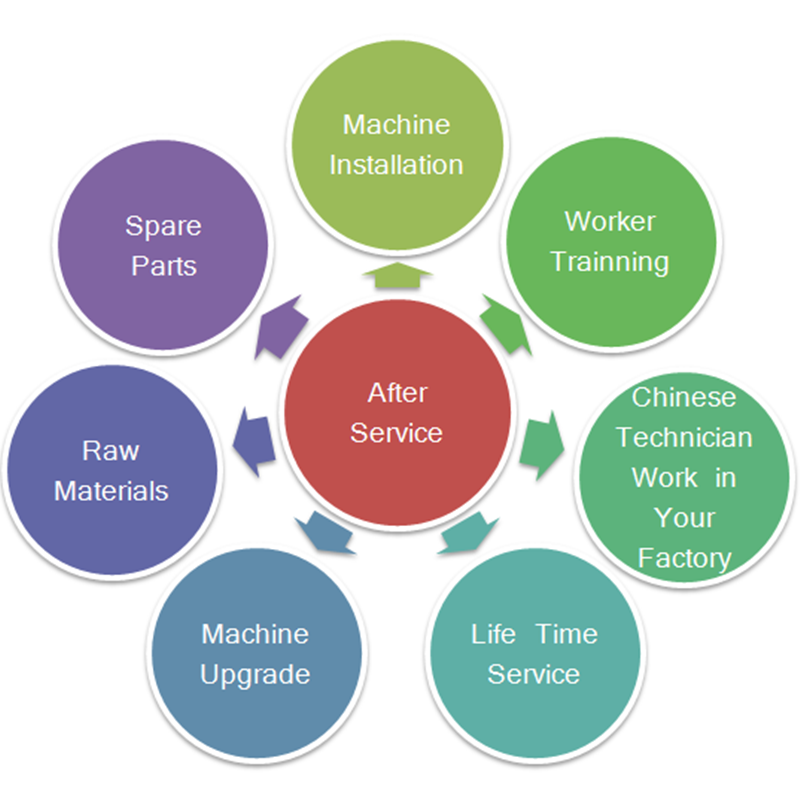

After-sales Service

X

X