This machine is used to making ultra thin sap paper for diaper & sanitary napkin absorbent core

1.This production line could realize a link production with fluffy nonwoven production equipment, effective control the product lose in the productive process. Promote the production efficiency.

2. Adopt modular construction design, PLC program control, integrated type HMI operation.

3. All main line drive by global famous brand frequency motor , SAP spread drive by Mitsubishi servo motor. Precision metrological materials spreading amount, measuring accuracy can control within ±3%.

4. Two section type unwinding mechanism with on-line nonwoven production equipment, non-stop, no need to speed down and auto splicing materials, reduce materials lose and time waste in the roll changing process. Effective capacity improvement. We configure patent structure for materials connection scheme. While ensure the strength of connecting materials, materials tails’ length is getting effective controlled.

5. Full automatic winding mechanism with auto roll changing function, alloy cutting knives online slitting product to be predetermined dimension.

1. Max design speed:70 m/min

2. Normal working speed: 30-60 m/min(no need to speed down while splicing)

3. Effective laminating width:2400 mm

4. Roller surface width: 2600 mm

5. Single-layer sap spreading amount:50g – 180 gsm

6. SAP spreading accuracy deviation : ±3%

7. Unwinding diameters for airlaid paper: ø1200mm

8. Winding diameters for laminated materials: ø1200mm

9. Finished product weight: 200-450 gsm , depend on client’s raw material

10. Electric control scheme: main line drive adopts closed-loop frequency converter adjust speed, sap shaft adopts servo drive

11. Overall dimension: 24500mm*4500mm*3500mm(L*W*H)

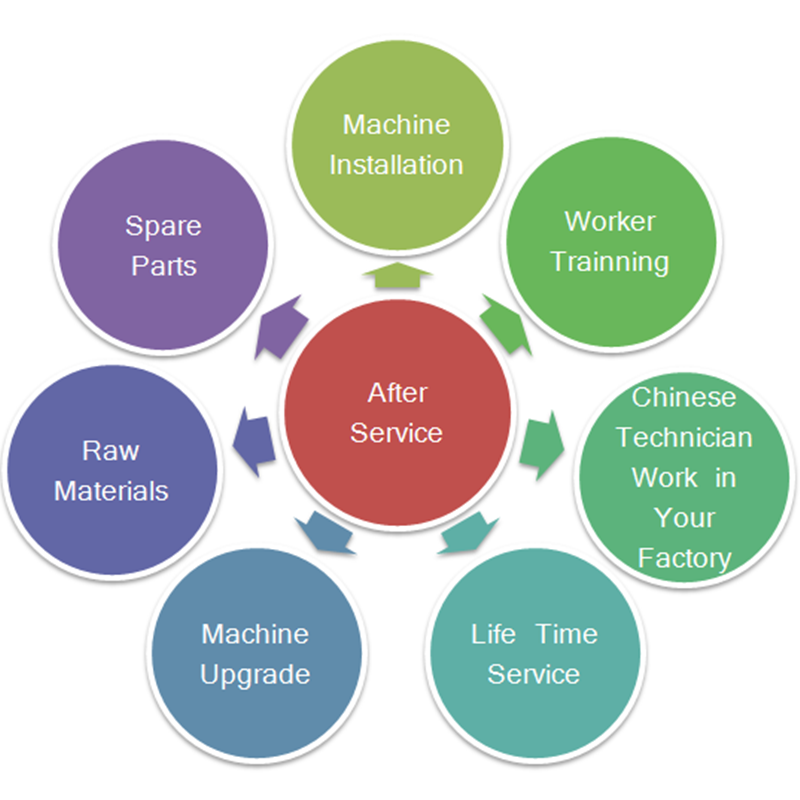

NISO is a professional raw materials and machine supplier for making baby diaper, adult diaper, feminine sanitary napkin,under pad and so on.

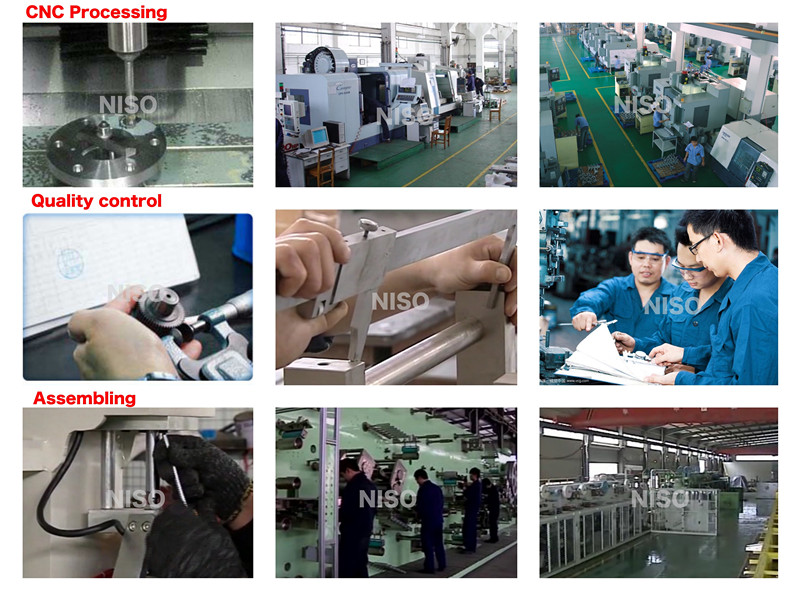

NISO covers an area of 5000 square meters, gets CE, ISO, SGS.

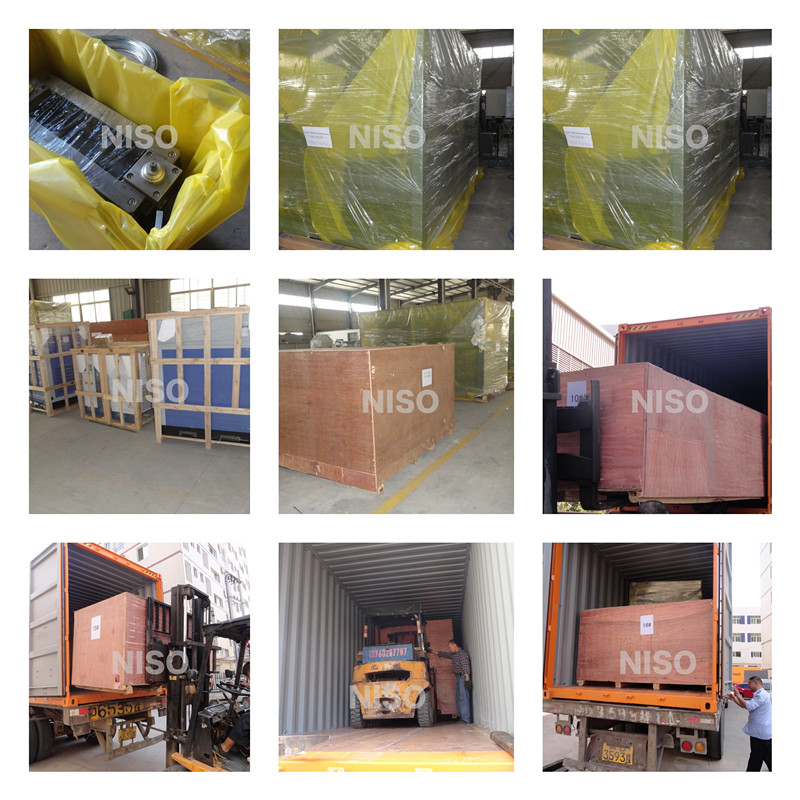

NISO exports more than1000 containers to Asia, Mid-east, Europe, South America, Africa countries.

NISO will be your consultancy and partner to reach win-win career together.

Quanzhou Niso Industry Co.,Ltd is your best choice for baby diaper machine, adult diaper machine, sanitary napkin machine and under pad machine in China.

X

X