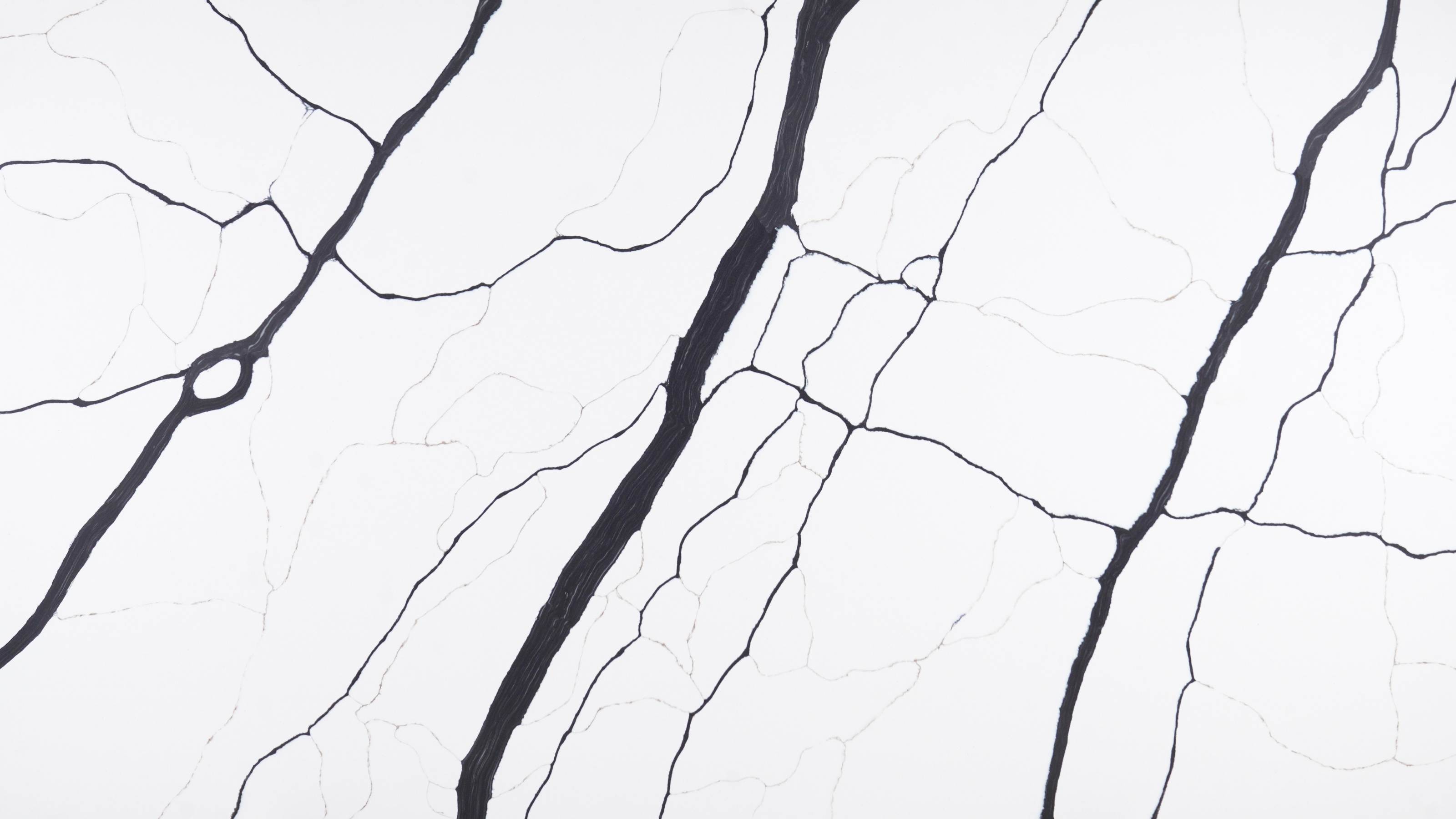

Unique natural solid high performance engineered quartz countertops

is a white backing quartz slab with bold, light abstract grey veins spreading across the slab area. And the middle bold veins are full of specialties.

Multiple and trendy design, veins, size, thickness for unique projects' requirements

Product Description

Multiple and trendy design, veins, size, thickness for unique projects' requirements

OEM, If want, we can print your brand mask on the slabs’ back side

Welcome to custom made color and design from us.

Packing

Projects experience

Welcome to custom made color and design from us.

How quartz is been made?

High purity 93% natural quartz powder, plus7% epoxy Resin or other decorative particles.

Raw material collection (raw quartz powder, glass, quartz, resin, etc.) →→Remove impurities( remove impurities, iron filings, etc. from raw materials) →→ Raw material allocation ( The materials are fully mixed in the gravity-free mixer to eliminate the problem of material color difference and uneven particles) →→ Stirring and mixing (Stir the unsaturated polyester resin, pigments, additives and granular powder thoroughly) → → Distribution (The stirred mixed materials pass through the conveyor belt and enter the fabric car, and then the material is evenly distributed into the fabric mold frame by the fabric car) →→ Vacuum high-frequency vibration pressing (After the cloth is completed, it is transferred to the press equipment and vibrated and pressed under the vacuum condition of -0.1MPa) →→ Heating, curing and shaping (After the pressing is completed, the blank is put into the curing furnace for heating and shaping at 85-110°C) →→ Thickness grinding (After the blank is solidified, it is cooled for 24 hours and then enters the thickness setting equipment for thickness determination) →→ Polishing: (After the thickness is determined, use a 20-head polishing machine for water grinding and polishing. According to different needs, polish until the gloss reaches requirements) →→ Inspection ( Inspect the appearance quality of the board) →→ Cutting (Use vertical and horizontal cutting and bridge cutting machines to cut the product to the required size) →→ Packaging and storage (The cut products are packaged after drying and stored in the warehouse)

Technical information

The main component of quartz stone countertop material is 93% quartz sand and resin, color or others. It feels very similar to stone.

|

Test item(s) |

Test method(s) |

Test result(s) |

|

Absorption by weight |

ASTM C97/C97M-15 |

0.05% |

|

Density |

2371 kg/m³ |

|

|

Abrasion resistance (polished) |

ASTM C241/C241M-15e1 |

44 |

|

Flexural strength |

ASTM C880/C880M-15 |

Dry condition:35.6 MPa |

|

Wet condition:40.1 MPa |

||

|

Compressive strength |

Refer to ASTM C170/C170M-17 |

Dry condition:248 MPa |

|

Wet condition:240 MPa |

||

|

Coefficient of linear thermal expansion |

ASTM C531-00(2012 |

22.2×10-6/C |

|

Specular gloss(60) |

ASTM D523-14 |

38.2 |

|

Stain resistance test |

Refer to ANSI Z124.6-2007 |

Total stain resistance value:56 Maximum individual depth of staining:0.04mm |

|

Composition analysis |

FTIR,PGC-MS,XRF and TGA |

See Page 9 |

|

Radioactivity |

GB 6566-2010 |

Class A |

|

Mohs'hardness |

Refer to EN 101:1991 |

6 |

|

Specimens identification No. |

1 |

2 |

3 |

4 |

5 |

|

Absorption by weight (%) |

0.04 |

0.05 |

0.05 |

0.05 |

0.04 |

|

Mean water absorption (%) |

0.05 |

||||

|

Density (kg/m³) |

2358 |

2372 |

2375 |

2373 |

2376 |

|

Mean density (kg/m³) |

2371 |

||||

major maintenance tips for quartz stone

①Daily maintenance: For oil stains, coffee stains, wine vinegar stains, sugar and salt stains, etc., just use warm water and soapy water. When encountering stubborn stains, use a white cleaning pad to remove them.

②Remove ink stains: Clean children's ink and handwriting with a wet rag and erase with rubber glue. If the stain cannot be removed, use washing powder and water in a ratio of 1:0.5, pour it on the stained area and soak it for about 5 minutes, and use a small Scrub with a brush until the stain is removed, and finally rinse with clean water.

③Remove rust: First use a wet rag to scrub the surface stains clean, then soak it with toothpaste, white vinegar or 84 disinfectant for 10 minutes, and then wash it with a rag.

④ Anti-scratch and avoid scratching: When cutting meat and vegetables, do not chop directly on the countertop. First put a layer of thick cloth on it, and then put the chopping board. Do not wipe it with steel balls, use a knife, or impact it with sharp objects, etc.

⑤Avoid long time heat: Although quartz stone is resistant to high temperatures, it cannot directly expose the heat to the countertop. Use heat insulation pads and heat insulation tripods to protect the countertop, especially the edges of the countertop.

⑥ Chemical resistance also requires avoiding chemical reactions: avoid cleaning chemicals containing bleach, corrosives, rosin oil, high alkalinity, xylene, toluene, potassium hydroxide, caustic soda, methylene chloride, trichloroethane and other chemicals.

How to start work with us?

Inquiry with detailed information ( color, chosen pattern, requested size, thickness, quantity ) →→ Counteroffer and confirming price by both sides →→ Checking sample →→

Sending 30% deposit to settle the order after checking performa invoice →→ Production

→→ Inspection →→ Paying rest for full set of documents to release the container →→ Quality and service feedback →→ Order completion

X

X