Steel Downspout And Elbow Roll Former is offer a complete package for making downpipe and its elbow products.

Description:

Steel downspout Roll forming machine And Elbow roll former/downpipe forming machine/ square downpipe machine/Round Downspout Roll Forming Machine/Pipe Elbow Curving Machine:

The pipe can make into square and round shapes and also dimensions can be designed as per buyer requirements. It can be fabricated from various material thicknesses and in almost any length. With tightly seaming and nice appearance, the auto forming line is capable well improved customer production capacity.

The elbow bending machine is capable to crimp out straight pipe with bending degree automatically after manual swing in straight pipes. Bending degree available 0~90 degree.

Working Procedure:

Uncoiling– Roll Forming Machine– Cutting– Collecting- Elbow Bending- Downpipe Joint

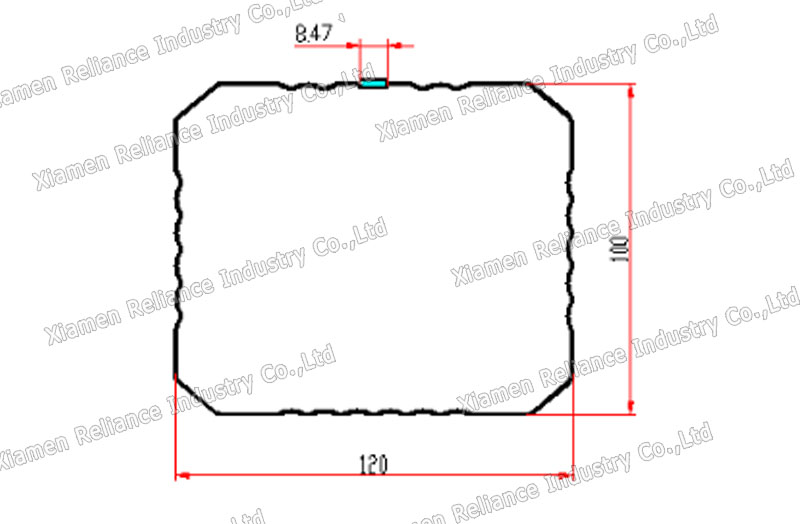

Profile drawing:

Material Thickness: 0.4-0.7mm

Applicable material: PPGI, Aluminum

With yield strength 250~350Mpa

Machine Components:

Feed Guide Device & Pre-shearing device

Smart cut control, to cut off the end of the final piece of sheet only

Working thickness up to 0.7mm

Main Forming Machine:

With feeding material guide, body base frame made of H frame steel by welding

Side wall plate thickness: Q235 t18mm

Rollers manufactured from 40Cr Steel, CNC lathes, hard Chrome Coated

with thickness 0.04~0.05mm

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving, 13-step+Idle rollers to form

Main Motor=7.5KW , Frequency speed control

All the screw bolts with grade 8.8

Max line speed 15 m/min (Not include cutting time)

Post Hydraulic Cutting Device

Post to cut, stop to cutting, two pieces type of cutting blade design, no blanking cut

Hydraulic motor: 3.0KW ;

Cutting tool material:Cr12, Heat treatment to HRC58-62 degree

The cutting power is provided by 3KW hydraulic station

PLC Control System :

Control The Quantity And Cutting Length Automatically

Input The Production Data (Production Batch, Quantity,Length,etc.) On The Touch Screen,

Then machine can proceed the production automatically.

Combined with: PLC (Siemens), Touch Screen (Siemens), Inverter (Schneider), Encoder (Omron), etc

Switch Bottom, Indicate Light, Power Supply, Intermediate Relay, AC Contactor,

Thermal Relay: Siemens/SchneiderCut-to-Length Tolerance≤±2mm

Control Voltage 24V

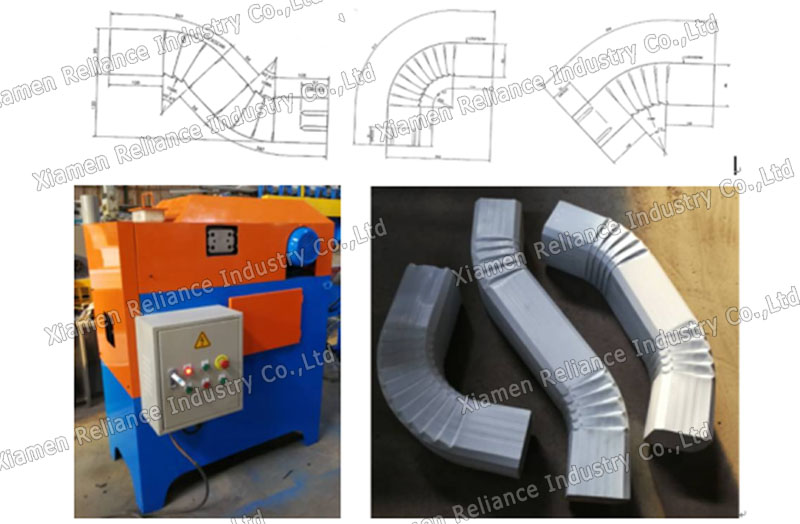

Elbow Curving Machine:

Electric driven elbow bending machine

Including the shrinking device for easy join downspout

Electric motor driven: 2.2KW, Curving speed 12m/min

Minimum bending degree 90

One set of elbow curving die

Loading Photos:

Elbow machine of downspout:

elbow curving machine:

down pipe elbow machine:

X

X