Cooling tower profile

The cooling tower adopts steel frame and glass fiber reinforced plastic enclosure structure, and is equipped with energy recovery type FRP air cylinder low-resistance high-efficiency flame-retardant strength water-filling filler, high-efficiency fan, low-resistance high-efficiency water collector.

The product can reduce the energy consumption of the chiller, save energy, ensure the efficient operation of the chiller, and is suitable for a variety of climates. Small in size, low in height, light in weight, beautiful in appearance, compact in structure and light in height, especially suitable for installation in indoors and balconies where the narrow height of the site is restricted, and the cooling effect is good and the running noise is low.

Difference between

square type crossflow closed circuit cooling tower and Traditional open cooling tower

The cooling water of the open cooling tower is in direct contact with the air in the packing for heat exchange, so the purity of the cooling water system cannot be maintained, and the cooling water inevitably absorbs dust and bacteria in the air. In the closed cooling tower, the cooling water flows in the coil, and the spray water and air are outside the disc, so the cooling water and the outside air are not in contact, and the purity of the cooling water system can be kept forever.

Square type crossflow closed circuit cooling tower working principle

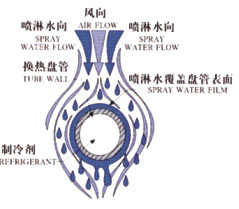

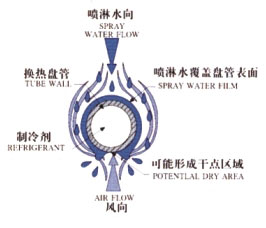

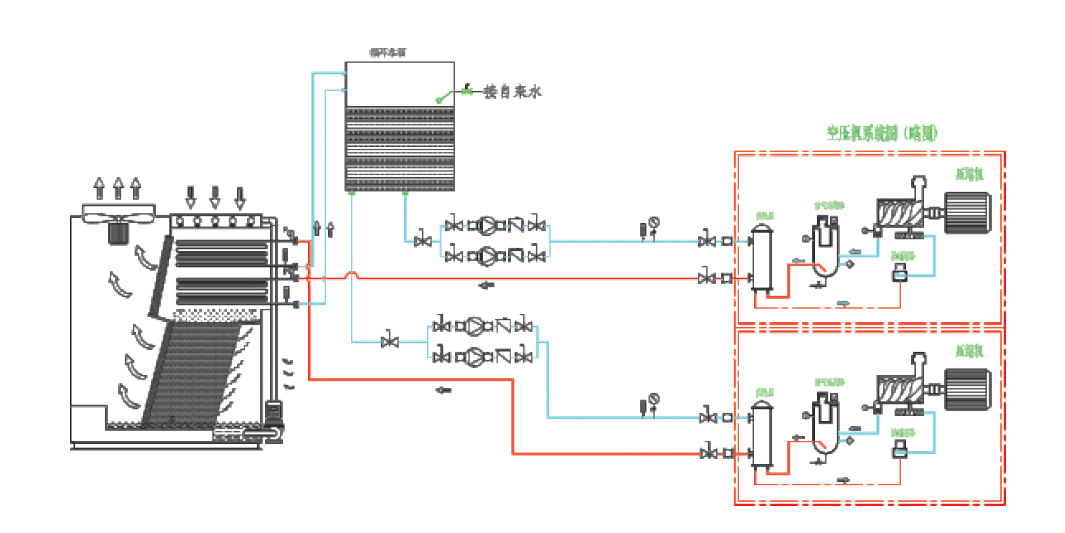

The working fluid (water, oil or other liquid) flows in the coil clock, the outer wall of the coil is wrapped by the spray water, the heat of the fluid is transmitted through the wall of the tube, and the saturated hot and humid air is formed with the water and the air, and the heat is discharged into the atmosphere by the fan. The parts are blocked and sprayed back to the sink, and the consumption is very small. The spray water reduces the water temperature through the PVC heat-dissipating material during the circulation process, and flows in the same direction as the fresh air. The coil mainly relies on the sensible heat conduction mode. An important feature of the principle is the maximum possible suppression of scale formation on the outer wall of the coil.

Square type crossflow closed circuit cooling tower Application industry

The cooling water of the cooling tower can provide cooling for the production process and the machine. The industries it adapts to are:

Air conditioning equipment industry

Metal processing industry

Energy industry

Chemical industry

Plastic products industry

Pharmaceutical Industry

Video processing industry

Square type crossflow closed circuit cooling tower working principle

The working fluid (water, oil or other

liquid) flows in the coil clock, the outer wall of the coil is wrapped by the

spray water, the heat of the fluid is transmitted through the wall of the tube,

and the saturated hot and humid air is formed with the water and the air, and

the heat is discharged into the atmosphere by the fan. The parts are blocked

and sprayed back to the sink, and the consumption is very small. The spray

water reduces the water temperature through the PVC heat-dissipating material

during the circulation process, and flows in the same direction as the fresh

air. The coil mainly relies on the sensible heat conduction mode. An important

feature of the principle is the maximum possible suppression of scale formation

on the outer wall of the coil.

1. Convenient transportation and installation

Factory assembly

Modular organization

Single-sided air intake and two-sided air intake

2. Excellent heat exchange performance

Low energy consumption, simple and reliable operation, and low maintenance costs. The product uses the combination of coiled water and coiled pre-cooling of the air and water co-flow mixed-flow secondary heat exchange to achieve efficient heat transfer. The air and cooling water flow in the same direction through the surface of the coil, ensuring that the cooling water can completely cover the surface of the coil, and the surface of the coil is always completely wet. Compared with the reverse structure of air and water, the formation of dry spots and scale on the surface of the coil is effectively avoided, and efficient heat exchange is realized. The cross-type water collection design strictly controls the drifting water loss, and its water rinsing rate is less than 0.001%.

3. Convenient maintenance, can achieve non-stop maintenance

The huge space inside the tower provides revolutionary convenience for the routine maintenance of the equipment. The repair of the coils at the key parts is simple and easy due to the structure of the equipment; the float valve and the filter can be repaired without stopping the machine. The nozzle and coil can be easily inspected while the unit is in operation.

4. Low operating costs, energy saving and environmental protection

The unique structure of this product, as well as its unique high thermal performance, so the working medium temperature is low, running nodes, water saving, low noise, no drifting and low maintenance costs, is a true energy-saving and environmentally friendly product.

5. Low failure rate

Both the fan and the pump are made of high quality bearings, and there are no other running wear parts.

The fan adopts a direct-connected structure and has no transmission loss caused by the pulley structure. Low noise and low failure rate.

6. Available for auxiliary equipment

For some small cooling projects, we can connect the closed cooling tower with the circulating water pump, circulating water tank and control system to form an integral model, which is convenient for users to use the product.

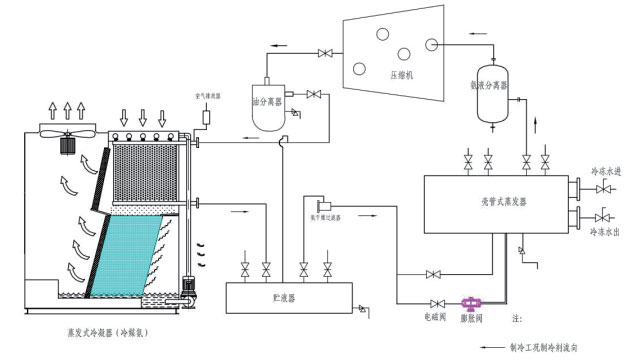

Structure diagram

1.Hot and humid air outlet

2.Fresh air inlet

3.Process fluid outlet

4.Process fluid inlet

5.Fan motor

6.Coil (copper pipe or steel pipe)

7.Water collector

8.Spray pump

9.PVC heat sink

10.Sprinkler system

Fan motor

The fan adopts aluminum alloy blade cooling tower special axial flow fan, which has high strength, large air volume, low energy consumption, low noise and long service life. The streamlined high-strength air cylinder ensures the inlet of the fan and the outlet airflow is uniform, minimizing the fan energy. Consumption.

The motor adopts a motor for the fully enclosed cooling tower, which is suitable for long-term continuous operation in a humid and hot environment. It has high efficiency, low noise, long life and high reliability.

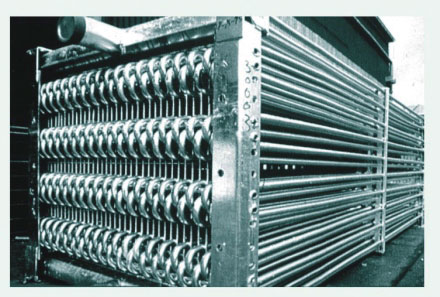

Heat exchange coil

The heat exchange coil is a key component of the cooling tower, and is made of a copper tube or a high-quality copper tube; the interior is cooled by a cooling medium, and the external water is sprayed to achieve cooling requirements;

Steel pipe (G type) or stainless steel pipe (S type), after grading and overall three 2.5Mpa strong pressure test, to ensure that the weld quality is 100% qualified, the whole pipe bundle is hot dip galvanized in the high temperature melting tank as a whole to ensure the coil Excellent performance.

Copper tube (T type): Deoxidized T2 high quality copper tube is used. The connection between copper tube and elbow is welded by silver electrode. The welding point is small and the quality is good. The design pressure is 1.2Mpa.

Stainless steel tube (S type): optional from 304 or 316 stainless steel. Its anti-corrosion ability can reach: NaCI solution with chlorine content of 750ppm; sulfide (such as S04) content of 1200ppm; calcification (such as CaCo3) content of 800ppm; silicon content (such as SiO2) of 150ppm, design operation temperature difference of 27.8 °C. The circulating water should not contain oil, fatty acids or organic dissolved substances.

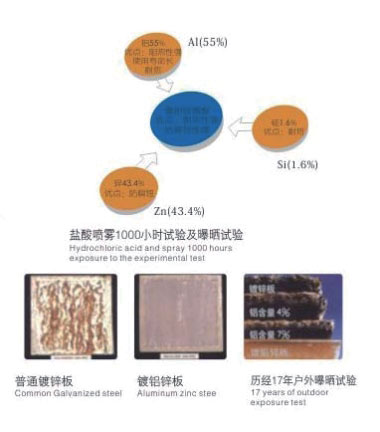

Protective panel

The cooling tower protective panel is made of imported galvanized sheet. It is one of the strongest corrosion-resistant galvanized sheets. Its service life is 3-6 times that of ordinary galvanized sheet, and it has strong heat resistance and excellent heat resistance. Beautiful appearance, etc.

Spray pump

It adopts high-quality mechanical seal that is not restricted by steering, has no leakage, long service life, and uses special outdoor type motor and special imported bearing to ensure long-term reliable operation of the pump, with low power, low lift, large flow, low noise, etc. Features.

PVC heat sink

PVC heat-dissipating filler is a film-type filler with an oxygen index of 33, which meets the national B1 flame-retardant standard. Each piece of packing has its own water collector and louver. The packing is suspended from a galvanized steel pipe supported by the tower structure.

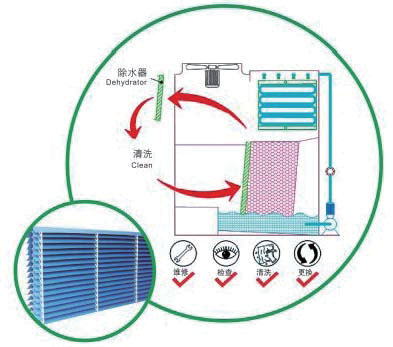

Water collector

The detachable water collector adopts high-quality PVC material, and its structure can effectively remove the moisture in the humid air by changing the flow direction of the air, so that the water drips rate is below 0.001%; maximally save water resources and ensure the tower body There is no pollution around, which can prevent the spread of Legionella bacteria.

Spray distribution system

The large-flow basket type nozzle is used to ensure that the cloth water is continuously and evenly sprayed on the wall of the coil. Under the action of the air, the water is wrapped to the surface of the coil to the maximum extent, so that the water, fresh air and the medium in the tube are fully exchanged. The nozzle and the nozzle are connected to the spray pipe for easy removal.

Electronic descaler (optional accessory)

Using electronic pulse technology to descale the circulating water, sterilizing and algae treatment, using 220V power supply, effectively reducing the formation of coil structure and filler surface structure

Immersion electric heater (optional accessory)

The heater is a stainless steel heater. During shutdown, in order to prevent the water in the collection basin from freezing, it is necessary to provide a system consisting of an electric heater and control immersed in water in each tower.

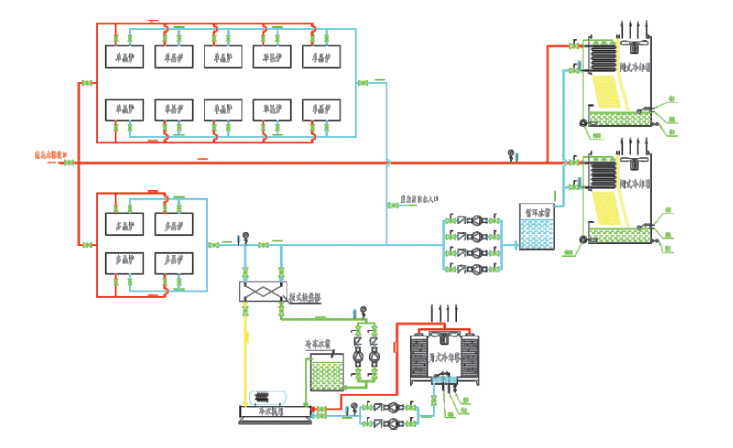

Application in the photovoltaic industry

In the photovoltaic industry, the safety of ingot PCW systems for single crystal furnaces and polycrystalline furnaces is extremely important, so the water quality of circulating water is extremely high.

Application in the machinery industry

High-speed equipment in industrial production will generate heat. These waste heats need to be drained in time to prevent high temperature damage, such as air compressor water jacket, reverse mold cooling, transformer cooling, and engine water jacket cooling.

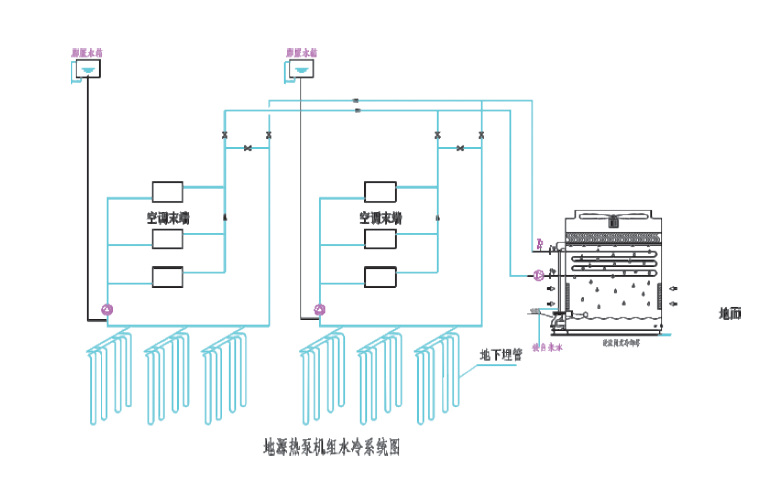

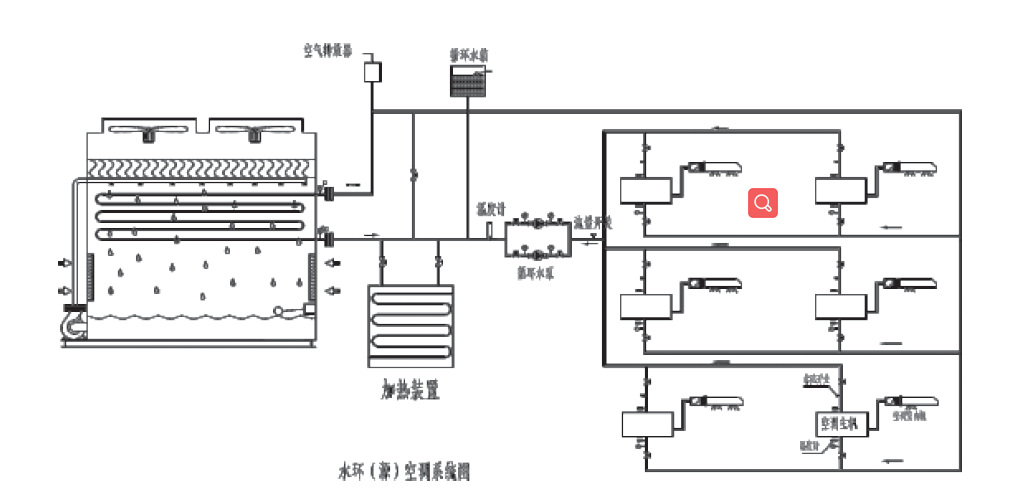

Application in the air conditioning industry

Evaporative condenser is used in the air-conditioning industry, and the condensing temperature and pressure are significantly reduced. The water-source heat pump system room air-conditioning system

Application in special industries

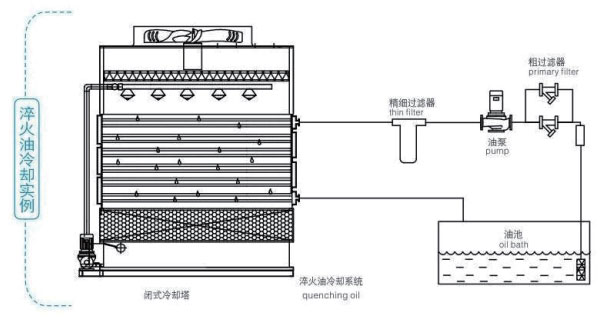

Cooling of special fluids in some industries because fluids cannot come into contact with the outside world. Quenching oil, sewage, emulsion, etc., need to use closed cooling method, the heat exchanger arm is generally tube box type, to facilitate maintenance.

Water ring heat conditioning system cooling

The safety of the equipment that needs to be cooled in the metallurgical industry clock is important, so the water quality of the circulating water is extremely high, such as the blast furnace circulating water in the iron making, the crystal library in the continuous casting, the oxygen furnace in the electric furnace, etc. High cooling water.

1, The requirements of the use of the environment

(1) Locations where acid exhaust, explosive dust, severe soot, and excessive water vapor should be avoided

(2) Placed beside the building and should be kept at a sufficient distance from the air inlet (05-3M, depending on the model)

(3) Placed in the well wall, should be alert to the hot air return caused by the hot air return, special circumstances can consider the air intake device

2, Piping problems

(1) Piping and pump valves should be installed below the operating water level of the cooling tower to prevent overflow and air inhalation.

(2) When considering the location of the equipment, there should be sufficient pump head, and the pressure loss along the path and the pressure loss of the cooling coil should be considered.

(3) The fluid flanged interface flange pressure is designed to be 1Mpa, all pipes are considered for hangers or supports

3, Consider fluid compatibility

(1) The fluid to be cooled by the fluid cooler must be compatible with the cooling coil, otherwise it will cause corrosion or blasting of the coil. For example, refrigerant ammonia is not compatible with copper tubes, and brine alkaline water is not compatible with carbon steel tubes and copper tubes.

4. Application in special industries

Cooling of special fluids in some industries because fluids cannot come into contact with the outside world. For example, quenching oil, sewage, emulsion, etc., need to use closed cooling method, the heat exchange arm is generally tube box type, to facilitate maintenance.

5, Capacity control

For multi-closed closed cooling towers, the number of running towers can be changed

For towers with multiple fans, the number of fans that can be changed

6, Spray system requirements

(1) With the operation of the closed cooling tower (evaporation cooling), part of the water evaporates, and the minerals and other impurities left in the water accumulate in the water tank, because the water quality must be checked regularly, and the sewage is cleaned regularly. Good control of water quality and prevention of scaling. The cleaning of the sink is generally recommended once a week in the summer and once every two weeks in the winter.

(2) Sprinkler water quality requirements: areas with particularly poor water quality should be treated with decontamination (softening), and it is recommended to use stainless steel.

(3) Replenishing amount of spray water

(4) Evaporation ≤ flow rate 08% + water liberation rate ≤ 0.1% + sewage discharge ≤ 03% = circulation flow ≤ 1.2

Sprinkler system antifreeze needs to consider one of the following three methods:

1. Set indoor insulation water tank, the flow tank has enough capacity, and all the spray water can be collected and moisturized when the machine is stopped.

2. Set the heater in the spray tank, generally using a submerged electric heater steam coil for heat injection

3. When the system stops running, drain the spray water clean.

7, Exhaust

The closed system of the fluid is operated. The steel pipe can be considered as a cooling coil. It can be fully enclosed or semi-closed. The steel pipe is used as a cold coil and must be fully sealed. The fluid is used to replenish the fluid. The gas in the pipe can be the highest in the pipeline. Install the automatic exhaust valve at the point. When the gas pressure reaches the set value, the valve will automatically open the gas. It can also be equipped with a manual exhaust device.

8, Supplementary water

The circulating water of the closed system can be demineralized water, demineralized water or condensed water, etc. due to the requirements of the production process for water quality.

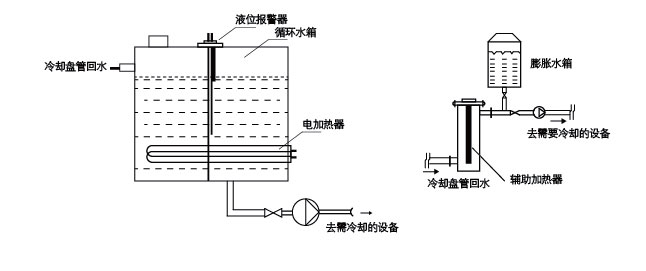

9, The cooling coil of the closed cooling tower antifreeze problem (very important)

When the temperature is low in winter, the circulating water of the closed system will not freeze even if the circulating water keeps flowing. There must be proper antifreeze measures. Generally, the following two methods are most suitable:

(1) Keep the circulating water at a certain heat load and ensure that the circulating water temperature is not lower than 7 °C (the warm area can be no less than 3 °C). To ensure this heat load, an immersed electric heater can generally be installed in the piping system. Or steam coil heat injector (Figure 1: set the electric heater in the water tank or set the auxiliary heater in the pipeline as shown in Figure 2) while maintaining a small flow of circulating water in the closed system.

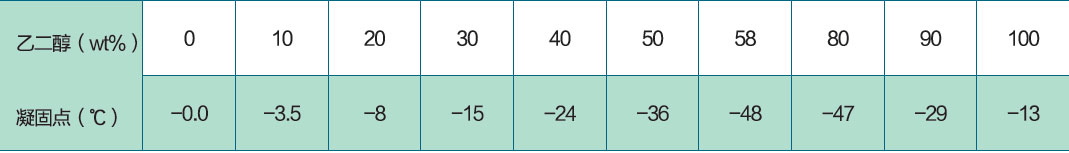

(2) The most effective method is to inject antifreeze, ethylene glycol or propylene glycol solution in a closed system. The proportion of the filling is as follows.

Antifreeze fitting ratio table

X

X