High energy efficiency with Single motor for two-stage transmission, Easy operation for saving efficient working

Efficient heat dissipation with natural ventilation on the sides Bamboo barrel that is resistant to wear and tear with cooling and self-cleaning effects Uniform polishing performance with free flowing grinding method.

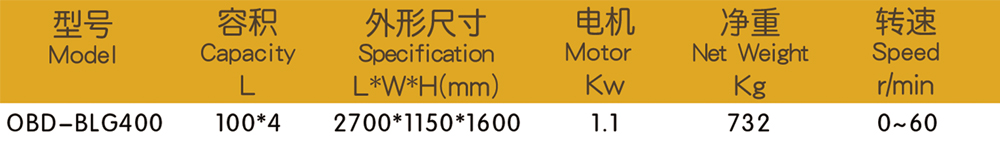

Rotary Tumbling Best Shiny Grinding Buffing Grinder And Tumbling Polisher Grinder Machine Grinder

The whole machine is divided into 4 separate drums. The material of the barrel wall is bamboo and wood. Bamboo wood can better reduce the use of rolling oil than the traditional wooden drum.

The grinding and polishing time is shortened as a whole by 4-9 hours.

Bamboo fiber: The density of bamboo fiber drum is higher than that of traditional wood material, which reduces the use of rolling oil. Better keep the inner barrel constant, so that

The workpiece is ground better and the polishing time is shortened

Automatic ventilation system: patented product, keeping the temperature inside the barrel to ensure that the product does not shrink due to high temperature shrinkage

Use / application area

Scope of application: metal fittings, hardware supplies, plastic tools, automobile and motorcycle parts, medical products, sheet glasses frames, etc.

For the surface treatment of acetate, plastic, metal and other products, improve the flatness of the surface of the product, brightness, for the subsequent processing

Efficiency and cost savings.

FAQ

Q: Which sulotions/machine/abrasive suitable for us ?

A:Wewill suggest the sulotions/machine/abrasive according to the testing report after free testing of your aplicationsifyou cansent us your products.

Professional advice:Our finishing specialists stand ready to provide answers to any question relating to specific surface finishing problems.Our decades of experience ensures that we will be able to provide you with the riaht answers

We have CE certificates for the products and IS09001 certificate for our factory.we have strict OC checking every details of the machine and full testing running before ship the machine.And we provide different wanrranties to the products.

X

X