STRPACK's positive displacement pump filling machines are best suited for filling viscous products, but they can be used to fill thin products as well. These fillers can handle a wide range of container sizes, fill volumes, and product types; but they are most ideal for filling pastes, creams, lotions, and gels, in large volumes and at greater speeds than otherwise achieved with a piston filler.

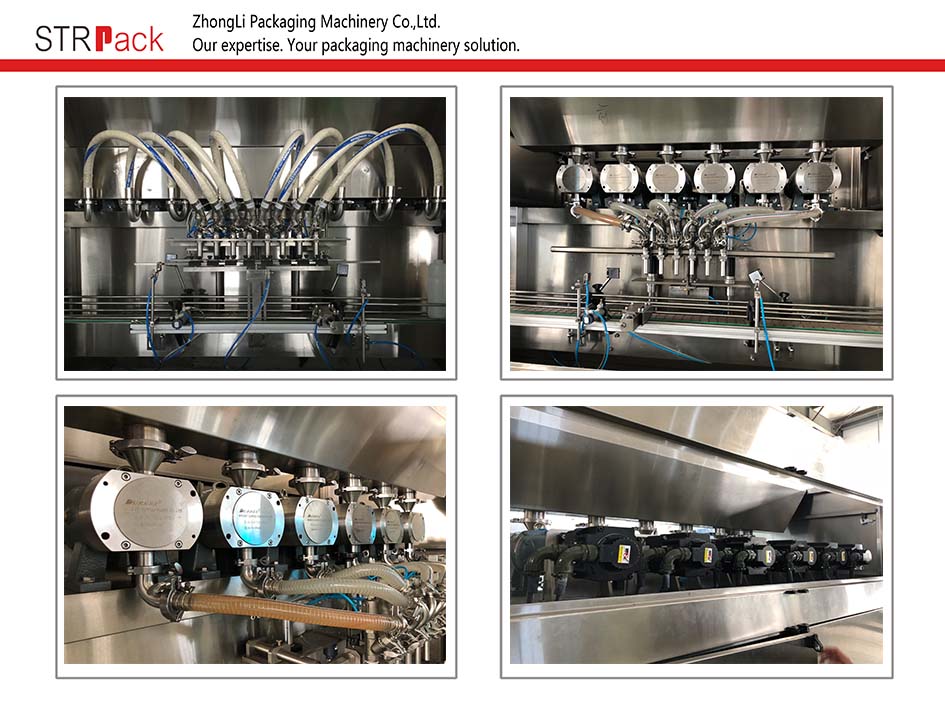

STRRP Rotor Pump Filling Machine

Brief Introduction:

Lobe Pumps

Like gear pumps, lobe pumps are a type of positive displacement pump that uses a rotary action to move product. Unlike gear pumps, a lobe pump will normally consist of about three lobes (versus the many teeth on the gear pump). Product is pushed throught the lobes in a manner similar to passing through the teeth of a gear pump. However, the extra space can be a benefit for products with small to medium particulates that may cause problems when passing through gears.

This filling machine is rotor pump filling machine which is made for filling high viscious product and non-flowable paste such as mayonnaise, sealant ,grease etc.

The machine is made by in-line structure , filling head quantity can be custom-made according to different production capacity such as 2/4/6/8 heads.

The filling system is driven by servo motor which assure high filling accuracy ,also easy to set filling volume on the touch screen directly.

It is widely used in the cosmetic, foodstuff, specialty chemical, pharmaceutical, and personal care industries.

Features:

Main Parameter:

|

Model |

Unit |

STRFP |

|||

|

Nozzle Number |

PCS |

6 |

8 |

10 |

12 |

|

Filling volume |

Ml |

100-10000ml |

|||

|

Production capacity |

Bottle/h |

1000-3000 pcs/Hour ( Depends on Filling volume) |

|||

|

Quantitative error |

% |

≤±1% |

|||

|

Voltage |

V |

380V/220V, 50Hz/60Hz |

|||

|

Power |

KW |

2.5 |

4.5 |

5.5 |

7.5 |

|

Air Pressure |

MPA |

0.6-0.8 |

|||

|

Air consumption |

M3/min |

0.8 |

1 |

1.2 |

1.2 |

X

X