Precision CNC machined components milling metal circuit board

These products are showed here only to present the scope of our business activities, we can also supply other goods which you need, parts are produced according to your drawings or sample.

It would be our proud to serve you at once we receive your valued enquiry with detailed specification and drawings, and we will submit our competitive offer ASAP.

JY Machinery is one of leading manufacturer of CNC turning, milling, drilling, grinding, laser etching and welding parts located in Xiamen, China.

1) Our factory is specialized in doing OEM/ODM products according to customers drawings or samples

2) Software for specification drawings: PRO/E, Auto CAD, solid work 2001, CAXA, UG, CAD, CAM

3) Advanced equipment, excellent R&D teams and strict quality control system

It's our pleasure to serve you if we get your inquiry with detailed specification and drawings, we will submit our competitive offer ASAP and provide you premium quality porduct.

Product Details:

Description:China customized CNC machining manufacturer

Metal Material:steel, stainless steel, carbon steel, brass, aluminum, alloy, etc

Application:Home appliance equipment,Auto parts,Industrial equipment,Electrical

Pricing:Factory direct price

Samples:Offer free samples

MOQ:Small orders accepted

Packing:Packed in plastic bag with carton for outer packing or as your request

Cost control:Most efficient production process design

QC control:100% inspection on critical dimensions

Management:Skilled workers and rich experienced staff

Manufacturing Capabilities:

|

Material |

1. Stainless Steel: SUS303, SUS304,SUS304L, SUS316, SUS316L, etc 2. Free Cutting Steel: 12L14, 1215, etc 3. Carbon Steel: 1010,1020, 1035, 1045, etc 4. Alloy Steel: 8620, 4140, 40Cr, 35CrMn, Titanium Alloy etc 5. Aluminum or Aluminum Alloy: Al6061, Al6063, etc 6. Brass: C3604, C3800, etc |

|

Surface Treatment |

Zinc plated, Nickel plated, Chrome plated, Passivation, Oxidation, Anodization, Black Oxide, Phosphatizing,Powder Coating and Electrophoresis, etc |

|

Processing Equipments |

CNC machining center, CNC lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM etc. |

|

MOQ |

There is no limit for MOQ, any quantity is ok |

|

Standard |

ISO, DIN, ANSI, JIS, BS and Customer Requirement |

|

Drawing format |

We accept DXF,DWG,IGS,STEP,and so on |

|

Terms of trade |

EXW, FOB, CIF |

|

Lead Time |

15-20 days after order confirmed or as your request |

|

Packing |

Single polybag, bubble bags, wooden case, carton box, or as your requests |

|

Logo |

Can be made as your own logo, your own brand |

|

After-sales Service |

We will follow up every customer and solve all problems satisfied after sale |

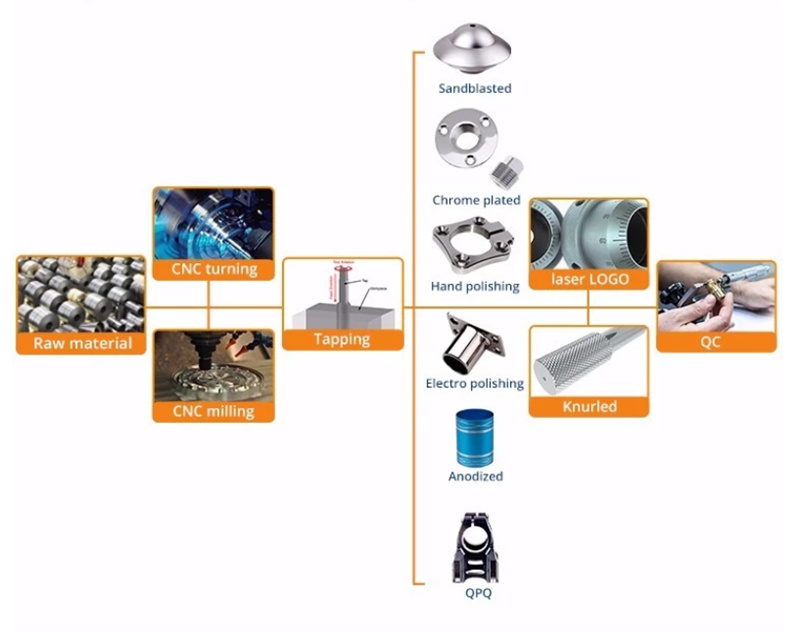

Production Process:

China cnc machined aluminum/stainless steel/brass/steel/titanium parts:

Our Factory:

Our Advantage:

1) Competitive price

2) High quality control : 100% full inspection before shipment

3) High precision, tolerance can be ± 0.002mm

4) Fast lead time (5-7days for samples, 12-15 days for mass production)

5) Non-standard//OEM//customized service provided

6) No MOQ, small QTY is acceptable.

7) Factory ISO 9001 certification, ROHS material used

9) Professional export packing: separate Blister plastic box or Bubble Wrap/Pearl Wool +Carton+ Wooden Case, keep no scratch and damage

Quality Control

Our principle is that no products are allowed to be produced without confirmation of the samples and drawing,meanwhile our company has the capability of production and quality controlling in the whole process from the selection of raw materials to the production of our products ,even to pre sales and after-sales service.We are able to ensure the stable quality of our products through controlling the key points with a variety of techniques and analysis means.

Testing Equipment:

Micro hardness tester, atomic absorption spectrometer, spectrophotometer, B&R&V three sclerometer, tool microscope, metallographic microscope, 3D imaging instrument, electronic universal testing machine, electronic balance, plug, two dimensional test instruments, pressure tester, tension tester, torque tester etc.

Raw Materials Control:

Surface Treatment:

|

As Machined |

Sharp edge and burrs will be removed |

|

Bead Blast |

The part surface is left with a smooth, matte appearance |

|

Anodized |

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. |

|

Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. |

|

|

Powder Coat |

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic. |

|

Customized |

Cotact us via email,skype,whatsapp. We will look into a finishing process for you. |

Package & Shipping:

FAQ:

Q: How Can I get a quotation?

A: We will submit the quotation in 8 hours if getting detailed information during working days.

In order to quote for you earlier, please provide us the following information together.

1). Detailed drawings (STP/STEP/IGES/IGS/PDF/CAD/DWG/DXF)

2). Material requirement

3). Surface treatment

4). Quantity

5). Any special demands or requirements, such as packing, labels,delivery,etc.

Q: What is your MOQ?

A: Without MOQ limited, trial order before mass production is welcomed.

Q: What is your machining scope?

A: CNC machining (including CNC Turning and CNC Milling), tapping, grinding, punching, laser etching (logo)/engraving, EDM related service.

Q:What about quality control?

A.: Self-inspection in every process by the production operator. Spot inspection and final inspection executed by inspectors. If you found any problems when received the parts,

please contact with us in time, we will provide a solution within 8 hours.

Q: What is the after-sales?

A: We will free remake parts or return payment if are sure that it is our error. This is our commitment. Quality is our culture!

X

X