Powder Filling & Packing Machine is an ideal bag packing equipment that meets the requirements of high-quality packaging and smaller bag type. The packaging speed is fast and can realize the three-side sealing and four-side sealing bag types.

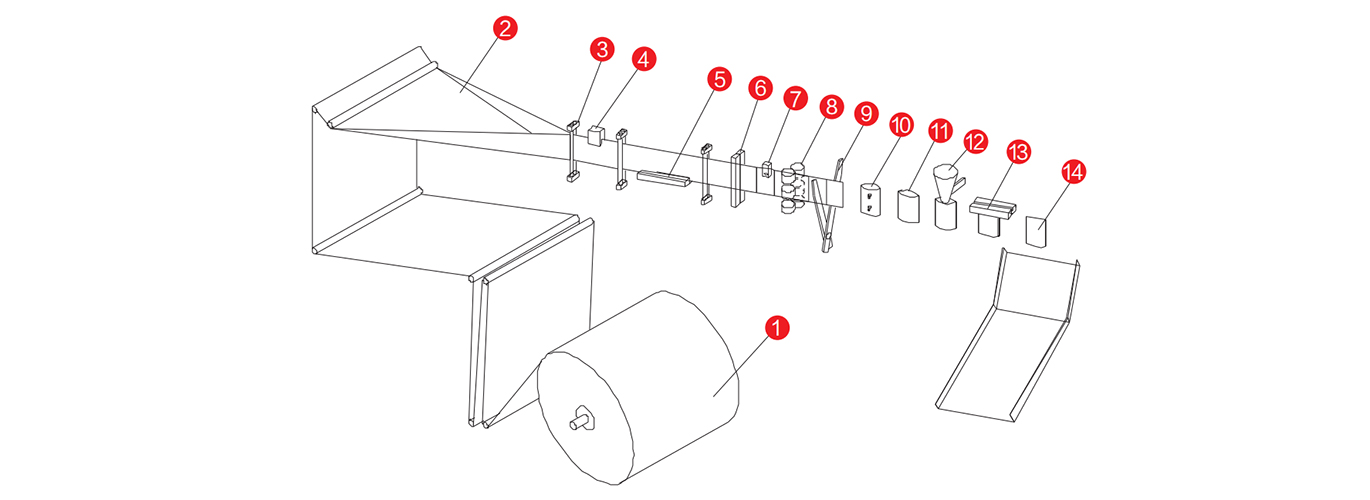

The Horizontal Form, Fill & Seal (HFFS) Sachet, Flatpack Pouch Packaging Machines are high-performance machines that eliminate the need for pre-made bags by using laminated roll stock film to create a large variety of flat pouch styles and reduce material cost dramatically. As opposed to purchasing pre-made pouches, cost savings of up to 30% may be incurred by producing a finished product in these machines. The DXD-180 is one of the larger machines in the DXD series of machines and makes, fills, and seals 3-side and 4-side sealed bags or Flatpacks, mold-cut shaped pouches, or flat spout pouches of premium quality and appearance.

Bag Types

The servo-driven HFSS machines can produce 3-side seal pouches and 4-sided seal flatpack pouches or flat pillow bags.

Filler Options

Machine Features

Machine Specifications

|

Model |

Function |

Pouch Size |

Filling Capacity |

Packaging Capacity (Max.) |

Electrical Consumption |

Pressure |

Air Consumption |

Machine Dimensions |

Weight |

|

DXD-180 |

3 side seal, 4 side seal |

60mm×75mm (Min.) |

400ml |

70ppm |

5kw |

0.6 Mpa |

200 NL/min |

3500mm(L) |

1400kg |

|

|

970mm(W) |

||||||||

|

180mm×225mm (Max.) |

1450mm(H) |

||||||||

|

DXD-180B |

3 side seal, 4 side seal,Twin-link |

60mm×75mm (Min.) |

150ml |

140ppm |

5kw |

0.6 Mpa |

250 NL/min |

3500mm(L) |

1400kg |

|

|

970mm(W) |

||||||||

|

90mm×225mm (Max.) |

1450mm(H) |

X

X