Polyurethane double side sealed rock wool sandwich panel gives full play to the unique properties of rock wool core material, and has remarkable effects in fire prevention, thermal insulation, sound absorption and sound insulation.

Polyurethane sealing edge rock wool sandwich panels

Polyurethane double side sealed rock wool sandwich panels has the advantages of polyurethane plasticity, sealing, high strength and non water absorption. The advent of this material is a revolutionary change in construction engineering, which fully integrates the advantages of polyurethane and rock wool, and eliminates the shortcomings of traditional panels.As thecladding of sandwich panel, the color steel material can be 100% recycled, which is really green and pollution-free.

Highlights of rock wool sandwich panels

1.Various colors:

Rock wool sandwich panels of different colors can be selected according to different styles of buildings.

2.Sound absorption and sound insulation

Rock wool sandwich panel has good sound absorption and sound insulation performance.

3.Waterproof and thermal insulation

Rock wool sandwich panel can be very good at waterproof, thermal insulation and fire prevention.

4.Long service life

Because the coating of color steel cladding works, the service life of Rock wool sandwich panel can reach more than15 years.

5.Easy installation

The installation of Rock wool sandwich panel is very simple, which can save a lot of construction time.

Product Specification

| Panel effective width[mm] | 950-1150 | ||

| Cladding thickness[mm] | 0.35--0.75 | ||

| Material of cladding | PPGL/PPGI sheet&Aluminum sheet | ||

| Core | Rigid mineral wool (nominal apparent density: 110 kg/m3) | ||

| Core thickness[mm] | 100 | 120 | 150 |

| Panel weight [kg/m2] | 20.3 | 22.4 | 25.6 |

| Insulating efficiency[W/m2K] | 0.38 | 0.32 | 0.26 |

| Panel thickness | Customized | ||

| Fire resistant level | A1 | ||

| Color | Customized | ||

| Panel length | 20FT,5.95m/40FT,11.95m | ||

Features

1) Sealing performance:Rock wool sandwich panels make use of the excellent waterproof of polyurethane products, overcomes the disadvantage of easy water absorption and deliquescence of rock wool, and effectively prolongs the service life of products in terms of physical properties.

2) Aesthetic performance: round and smooth appearance, flat and beautiful board surface, tight joints and reliable strength.

3) Good stiffness: after the sandwich panel is fixed with the purlin through the connector, the overall stiffness of the roof is greatly improved and the overall working performance of the roof is strengthened. Rock wool sandwich panel can be used with large purlin distance, which can save 1 / 3 ~ 2 / 3 of purlin consumption.

4) Reasonable buckle connection method: theRock wool sandwich panel adopts concealed buckle connection, which avoids the hidden danger of water leakage at the roof panel joint and saves the amount of accessories.

5) Short installation period: the average daily installation area of rock wool sandwich board is 600 ~ 800m2.

6) Scratch protection: during the production of Rock wool sandwich panels, polyethylene self-adhesive protective film can be pasted on the surface to avoid scratch or wear on the surface coating of steel plate during transportation and installation.

Application

Sandwich panels with a mineral wool core are non-flammable.

They can be used in projects which require above-standard fire protection ratings. It is widely used for the ceiling and partition of the roof, wall and air clean room of steel structure workshop and simple movable room.

Product display

Packing & Delivery

◆Packing:

Seaworthy packing standards:

PVC on both sides to protect the roof panel ends;

Packed with paper to protect the panel ends;

Put EPS foam on the each space to keep the panel from squeezing each other.

If you have special requirements,please feel free to discuss with us.

This is to make us improved and protect your goods well.

◆Delivery:

Delivery time for regular colors,coating types and thickness:7-10 days;

Delivery time for special colors,coating types and thickness:20-30 days;

Delivery terms:FOB/CIF/CFR/DDP is available;

We can find good forwarder for customer or accept appointed forwarder from customers.

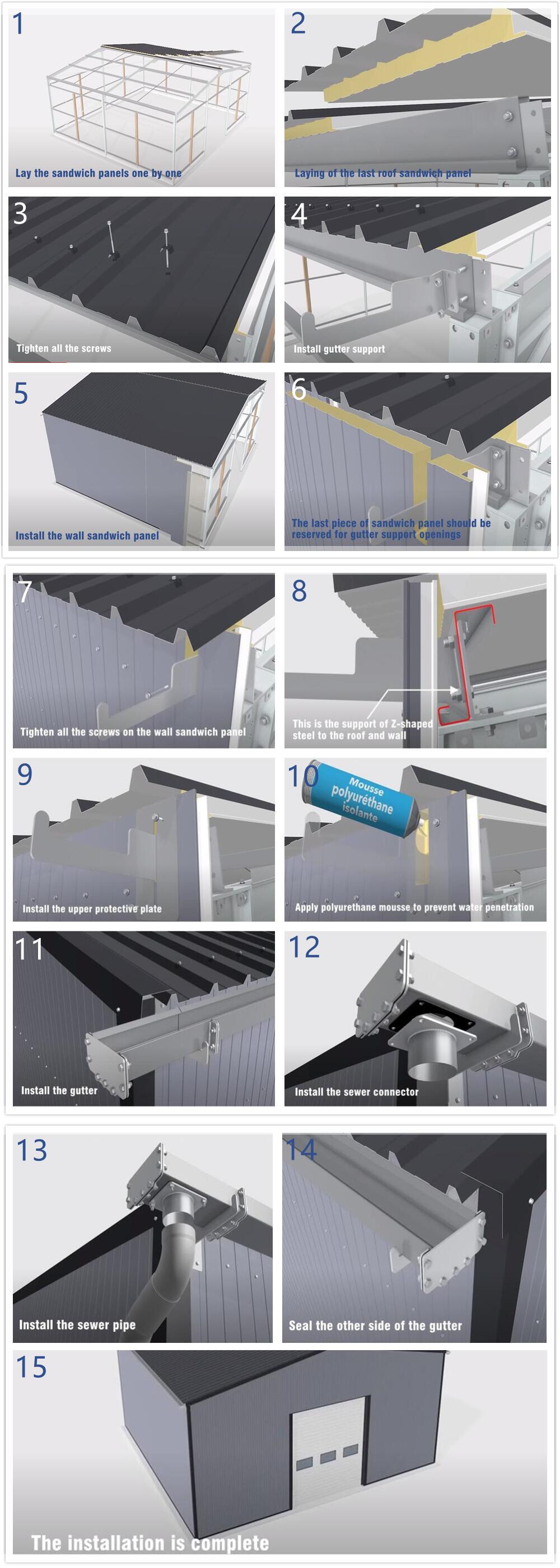

The installation of sandwich panels is relatively simple. Let's take a small house as an example to show you how to install sandwich panels.

If you have any questions about the installation of this product, please contact us and we will send you a detailed installation instruction.We can also tell you how to easily solve the installation problem in the email : syinhuan@chinayinhuan.com

X

X