The rotary vibrator is wildly uesd for applications in different size,shape and materials including metal,plastic,ceramic,rubber stone and wood. It can be used for deburring,surface grinding,descaling,de-oiling,cleaning,radiusing and polishing of stampings,machine components,saw-cut,custom-ben,forgings andcastings."Vibration Wheel Polishing Machine""Deburring Barrel Polishing Machine"Deburring Machine""Vibration Polishing Machine For Metal"

"Vibration Polishing Machine Wheels""Wheel Polishing Machine Vibrator""Automatic Deburing Polishing Machine"

"Vibration Finishing Polishing Machine""Polishing Machine Polishing Machine""Polishing Deburring Machine""Surface Metal Polishing

Industrial Vibratory Polishing Machine Grinding Polisher Tumbler Equipment Bowl

Successful mass finishing applications are usually the result of a combination of creative process technology and innovative equipment engineering. This approach is reflected in the varied line of Jintaijin rotary vibrators with their enhanced performance characteristics. They combine Jintaijin’ s high equipment quality and reliability standards with a functional design. In addition, they are easy to operate and provide a high degree of productivity.

Various types of our vibrators,combane with different abrasive and compound,supply various options customers.

Functionable:

Functionable include:de-burring,grinding,radiusing,general parts cleaning,casting,formed,forged and saw-cut pa ts as well as machined components.

Special machine Versions

FAQ

Q: Which sulotions/machine/abrasive suitable for us ?

A:Wewill suggest the sulotions/machine/abrasive according to the testing report after free testing of your aplicationsifyou cansent us your products.

Q: What after-sale service do you provide ?

A:Installation and training:Machine installations and operator training are performed by our team of highly skilled and experienced service enaineers

Spare partsservice:We maintain a complete inventory of spare parts in warehousedelivery to you in time.

Maintenance and repair service:We maintains a well trained staff of professional field service engineers to provide prompt reliable maintenance and repair service at competitive rates,as well as overhauls of your older eauipment

Professional advice:Our finishing specialists stand ready to provide answers to any question relating to specific surface finishing problems.Our decades of experience ensures that we will be able to provide you with the riaht answers

Q: How do you insure the quality ?

We have CE certificates for the products and IS09001 certificate for our factory.we have strict OC checking every details of the machine and full testing running before ship the machine.And we provide different wanrranties to the products.

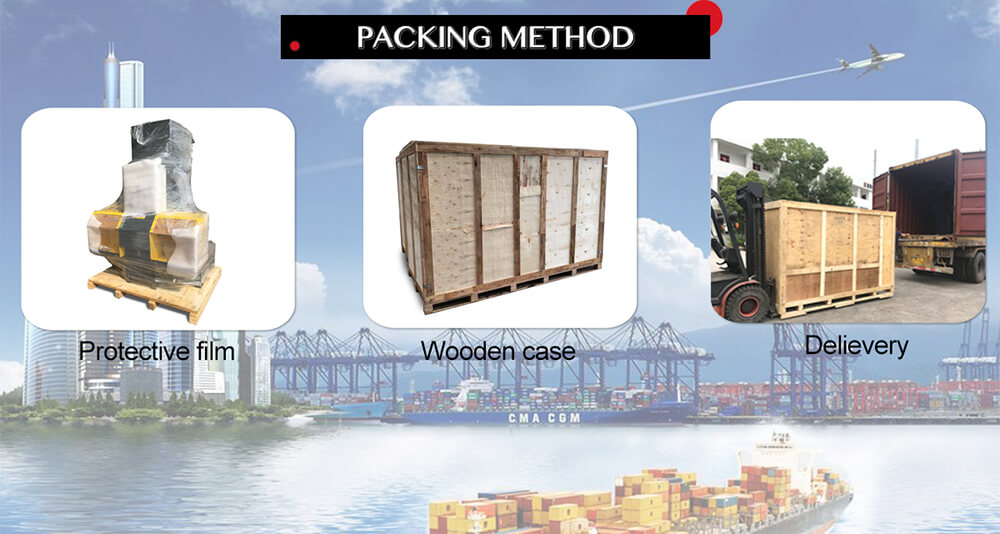

O: How about the delietverv ?

Thepaymentterms is 30% deposit and 70% balance before shipment. And 15~30 days for production.1~3 days for stocks.The packaae always be wooden case.and we could arrange shipment for you by sea by air or by express(Door to Door

"Vibration Wheel Polishing Machine"

"Deburring Barrel Polishing Machine"

"Vibration Polishing Machine Wheels"

"Wheel Polishing Machine Vibrator""Automatic Deburing Polishing Machine"

"Vibration Finishing Polishing Machine""Polishing Machine Polishing Machine""Polishing Deburring Machine""Surface Metal Polishing Deburring Machine""Vibration Polishing Machine For Metal"

X

X