Fork positioners can easily handle pallets with different widths to help meet complex material handling demands. The M series fork positioner allows you to hydraulically move the forks closer together or further apart, individually or together. This is particularly useful when you have to handle a variety of pallet sizes. Damage to pallets and products will be reduced as well.

New Integral Side Shifting Fork Positioner

Fork positioners can easily handle pallets with different widths to help meet complex material handling demands. The M series fork positioner allows you to hydraulically move the forks closer together or further apart, individually or together.

This is particularly useful when you have to handle a variety of pallet sizes. Damage to pallets and products will be reduced as well.

Important parts configuration:

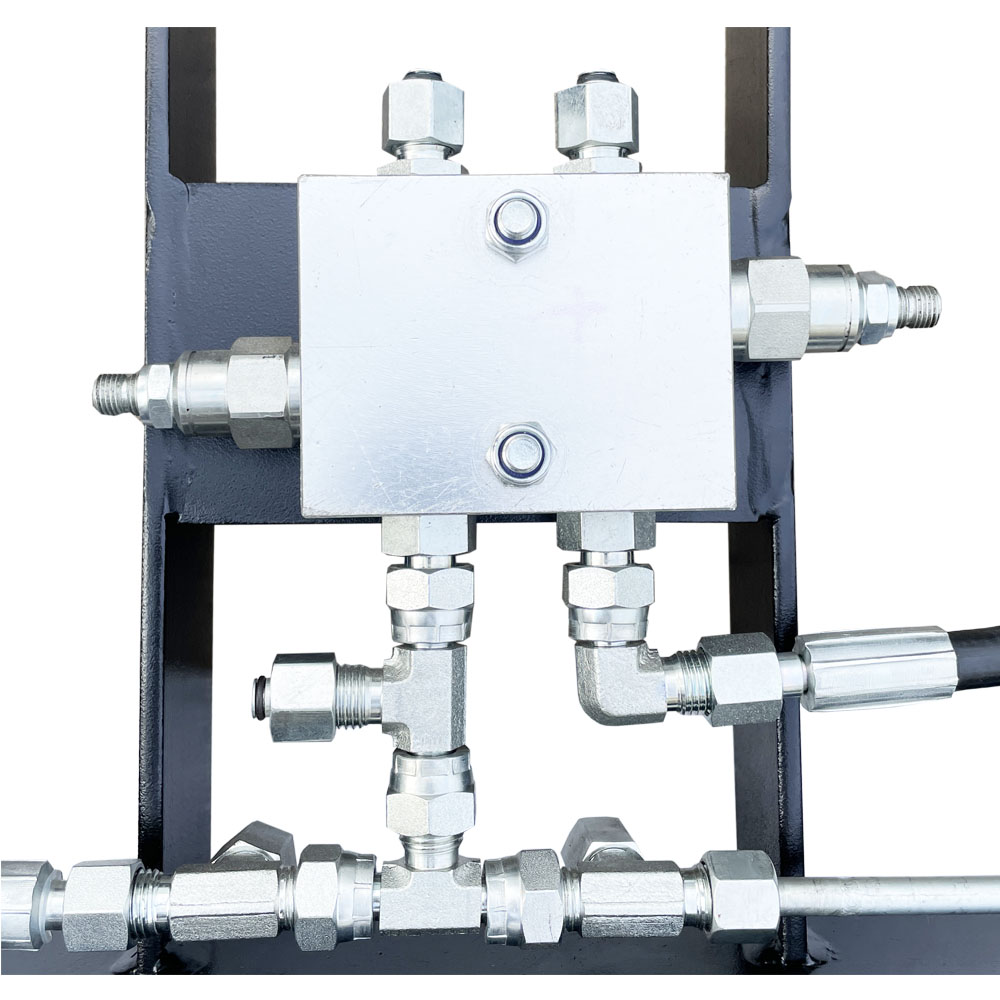

Hydraulic system: The use of multi-functional combined control valve, with 24° cone seal, greatly improves the reliability of the hydraulic system.

Structural parts: The shift fork is made of integral alloy steel castings, with beautiful appearance and reliable performance.

Mechanical performance: The use of control valves to ensure that the two forks can run synchronously, the forks are controlled by double cylinders, and the stability is good;

the standard forks of the forklift are used, which has good versatility and easy installation.

Important parts configuration:

Hydraulic system: The use of multi-functional combined control valve, with 24° cone seal, greatly improves the reliability of the hydraulic system.

Structural parts: The shift fork is made of integral alloy steel castings, with beautiful appearance and reliable performance.

Mechanical performance: The use of control valves to ensure that the two forks can run synchronously, the forks are controlled by double cylinders, and the stability is good;

the standard forks of the forklift are used, which has good versatility and easy installation.

Side shift function is optional, the specific configuration is:

Only fork positioner,no side shift,2 sets of additional oil circuits are required (no control valve);

Fork positioner and side shift,2 sets of additional oil circuits are required (with control valve);

Only fork positioner,no side shift,1 set of additional oil circuits are required(with control valve);

Note:

1. Please obtain the actual comprehensive load capacity of the forklift/attachment from the forklift manufacturer.

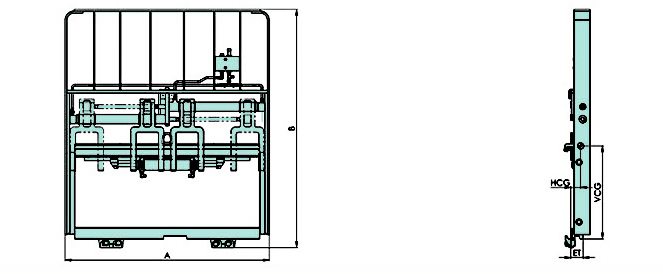

2. Fork pitch range: the minimum value is the inner distance of the two forks when the forks are closed, the maximum value is the outer distance of the two forks when the forks are opened.

3. Non-standard sizes not included in the form need to be booked separately.

Model

Pressure(Bar)

Flow(L/min)

Max.

Min.

Rec.

Max.

M**G

180

11

15

19

Capacity@

Load Center

Mounting

Class

Opening

Range

Total

Side Shift

Fork pocket

width

Min. Truck

Carrier Width

Overall

Width

Overall

Height

Effective

Thickness

Horizontal of

Gravity Centre

Avaliable

Forklift

Model

Weight

M18G-A1

1800@500

2

100-900

±100

100

895

1018

1245

139

62

50

1-1.8T

M25G-A1

2500@500

2

100-970

±100

100

940

1088

1245

152

62

50

2-2.5T

M30G-A1

3000@500

3

100-1025

±100

125

970

1148

1336

182

68

50

3-3.5T

M45G-A1

4500@500

3

100-1300

±100

150

1180

1428

1345

260

70

50

4-4.5T

X

X