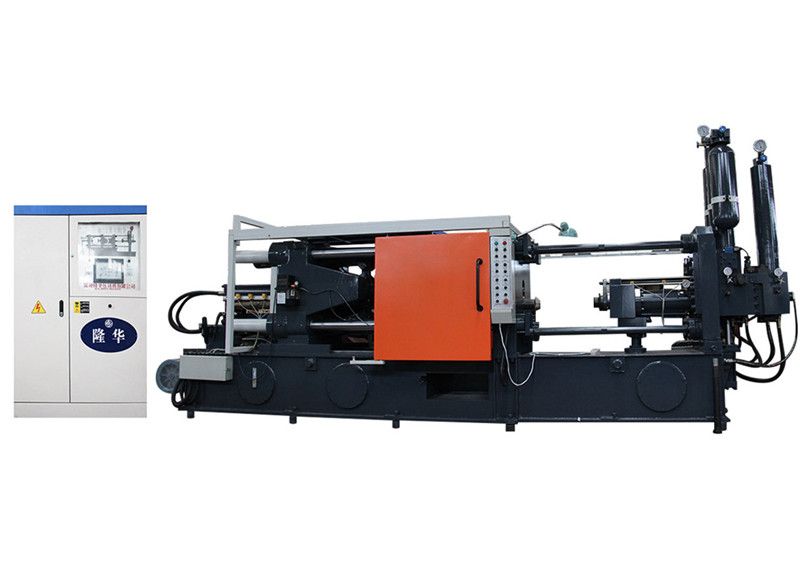

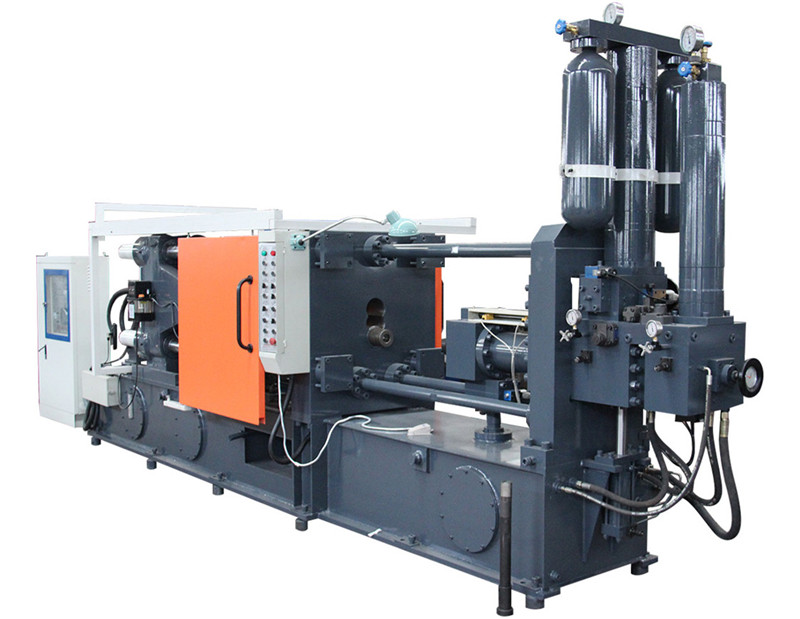

Longhua die casting machine design is reasonable, safe and reliable to use, fully meet the production technology requirements of all types of die casting, strive to create a new, service to the majority of customers.

Product Item:

New design Intelligent die casting machines to make aluminum motor housings(LH-350T)

The cold chamber die casting machine drives the die casting mold to close and open. When the mold is closed, it has enough ability to lock the mold to ensure that the parting surface of the mold will not expand during the injection filling process. The clamping force of the mold is called the clamping force (also known as the mold matching force), and its unit is kN, which is the primary parameter to characterize the size of the die casting machine.

LH SERIES OF STANDARD PARAMETER TABLE (LH-350 T)

|

ITEMS |

UNIT |

SPECIFICATION |

|

HYDRAULIC WORKING PRESSURE |

MPA |

14 |

|

CLAMPING FORCE |

KN |

3500 |

|

SPACE BETWEEN TIE BARS |

MM |

600*600 |

|

TIE BAR DIAMETER |

MM |

¢120 |

|

DIE OPENING STROKE |

MM |

500 |

|

INJECTION FORCE(INTENSIFY) |

KN |

360 |

|

PLUNGER LAUNCH DISTANCE |

MM |

180 |

|

INJECTION POSITION |

MM |

0 -- 160 |

|

PLUNGER DIAMETER |

MM |

¢50----¢80 |

|

INJECTION STROKE |

MM |

480 |

|

CASTING PRESSURE (INTENSIFY) |

MPA |

184/127/94 |

|

CASTING FIANGE PROTRUSION |

MM |

12 |

|

CASTING FIANGE DIAMETER |

MM |

110 |

|

MAX CASTING AREA UNDER 40MPA |

CM2 |

875 |

|

LNJECTION WEIGHT(AL) |

KG |

3.8 |

|

DIE HEIGHT(MIN--MAX) |

MM |

250~750 |

|

EJECTOR FORCE |

KN |

180 |

|

EJECTOR STROKE |

MM |

110 |

|

MOTOR CAPACITY |

KW |

18.5 |

|

MACHINE DIMENSIONS (L*W*H) |

M |

6.8*1.8*2.7 |

|

REFERENTIAL MACHINE WEIGHT FOR UPLIFTING |

T |

14.2 |

|

OIL TANK CAPACITY |

L |

700 |

PS:WE RESERVE THE RIGHT TO MAKE ANY TECHNICAL IMPROVEMENT WITHOUT FURTHER NOTICE

Features of cold chamber die casting machine

(1) Suitable for die casting of zinc, aluminum, magnesium, copper and other alloys;

(2) The production site USES less, and most of them are minicomputers;

(3) The pressure chamber is placed vertically. After pouring metal liquid into the pressure chamber, the gas is above the metal liquid.

(4) The pressure transfer is affected due to many turning points of the injection pressure, especially in the pressurization stage. Due to the small orifice at the nozzle entrance, the pressure transfer is not enough.

(5) Convenient for opening center gate;

(6) The length direction of the machine covers a small area, but the height of the machine is relatively high;

(7) It is not convenient to troubleshoot when the metal solution is tampered with the lower punch;

(8) In the production operation, there are procedures to cut off the surplus cake and give out the cake, reducing the production efficiency;

(9) When adopting automatic operation, add the procedure of removing residual cake from the top surface of the bottom punch.

X

X