The surface finishing compound is an important part of the finishing process,and the right compound makes the difference between a good surface finish and a great surface finish. Compounds keep the surfaces of the media and components clean, and can also provide corrosion protection and/or degreasing.

In order to determine the right compound for the process you must consider: 4 the >material the component is made of

> the required surface finish

>the individual application and process requirements

Due to the ease of dosing, liquid compounds are most widely used with modern finishing systems. Powder compounds are recommended for special applications such as shock degreasing and media cleaning.

Surface Finishing Compound

Our compounds are ideal for all surface finishing processes. Their manufacture combines environmental protection, precision, and quality of process technology.

Our Research and Development process takes place both in our development laboratory and in our test centres worldwide. We are continuously improving our products, as well as developing new ones, ensuring that we can always provide the right compound to fit your process and your budget.

Thorough testing of raw materials and finished products according to DIN EN ISO 9001 standards allow us to fully document the quality

control used in the production of our consumables.

Regardless of which of our products you utilize, you can be sure that environmental protection will be a part of your surface finishing process.

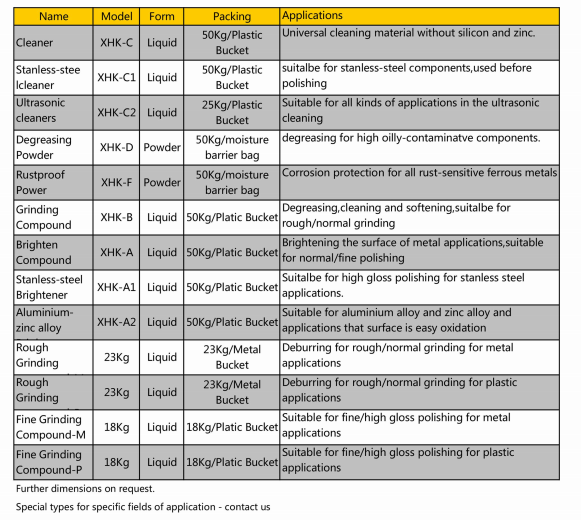

Liquid Compounds

The liquid compounds are the foundation of the modern surface finishing process. Thanks to their ability to remove contaminants such as metal and/or media fines from the process, they keep the components and the media clean and ensure that the media perform properly.

Choose the right product for your application from our product range. This will guarantee that your solution is both economical and environmentally-friendly.

Dry Compounds

Dry polishing media corn cob and walnut shells are treated with dry polishing compounds for use in rotary vibrators, high-energy centrifugal systems, and barrels. This media/compound combination works to achieve a fine, smooth high-end polish with a bright luster on ductilesurfaces. We can also adapt both media and compounds for specialised applications.

All dry polishing media is ready to use, and available in a variety of sizes.

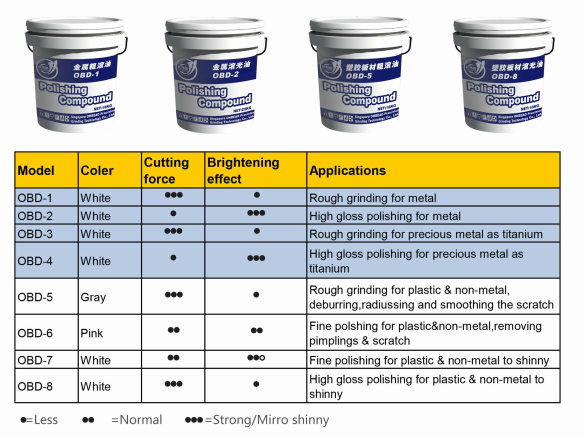

Grinding And Polishing Paste

The Ginding and polishing process refines, superfinishes, and produces mirror-bright, high polish surfaces. our polishing pastes are designed to produce the required surface finish, are environmentally-friendly, and economical to utilise. In addition to pastes, we have also developed powdered products for use with recirculation systems.

Polishing Powder Compounds

FAQ

Q: Which sulotions/machine/abrasive suitable for us ?

A:Wewill suggest the sulotions/machine/abrasive according to the testing report after free testing of your aplicationsifyou cansent us your products.

Professional advice:Our finishing specialists stand ready to provide answers to any question relating to specific surface finishing problems.Our decades of experience ensures that we will be able to provide you with the riaht answers

We have CE certificates for the products and IS09001 certificate for our factory.we have strict OC checking every details of the machine and full testing running before ship the machine.And we provide different wanrranties to the products.

X

X