| ITEM | Unit | LS650 | ||

| Clamping Force | kN | 6500 | ||

| Clamping Stroke | mm | 680 | ||

| Ejector Force | kN | 300 | ||

| Ejector Stroke | mm | 160 | ||

| Die Height(Min.-Max.) | mm | 350-900 | ||

| Platen Size(HxV) | mm | 1290X1290 | ||

| Space Between Tie Bars(HxV) | mm | 850X850 | ||

| Injection Force(with intensification) | kN | 600 | ||

| Injection Stroke | mm | 650 | ||

| Plunger Diameter | mm | 70 | 80 | 90 |

| Injection weight | kg | 4.6 | 6.1 | 7.7 |

| Casting Pressure(with intensification) | MPa | 155 | 118 | 94 |

| Casting Area | cm2 | 416 | 544 | 689 |

| Max. Casting Area (40MPa) | cm2 | 1625 | ||

| Shot Injection Postion(below center line) | mm | 0,-250 | ||

| Plunger Penetration | mm | 280 | ||

| Diamater Of Pressure Chamber Flange | mm | 165 | ||

| Height Of Pressure Chamber Flange | mm | 15 | ||

| Hydraulic Working Pressure | MPa | 16 | ||

| Hydraulic Oil Tank Capacity | L | 1100 | ||

| Machine Dimensions(LxWxH) | mm | 7800X2120X2960 | ||

Product Advantages:

Lanson die casting machines are designed and manufactured according to international standards. Combining the latest technology with a wealth of die casting machine operational experience and theories. Lanson created the proprietary new generation die casting machine. Equipped German Siemens control system with powerful functions and stable operation. The real time control system concerned as the leading technology in China, makes the injection system meet the world class. The design of strong and efficient clamping system makes the force condition of the toggle unit more reasonable, machine operating more smoothly and the system more rigid. The reasons above make Lanson machine become the first choice for automotive parts, electrical appliance, telecommunications and all high-end die casting products.

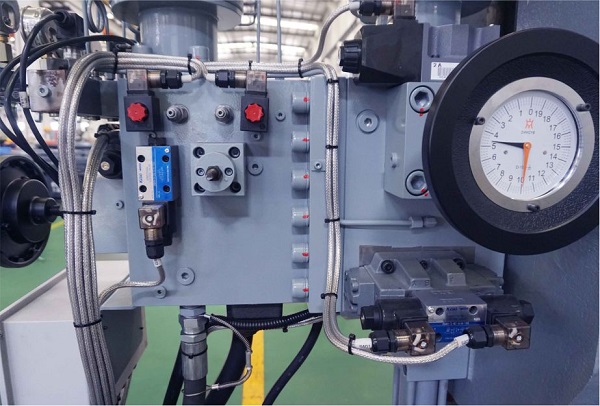

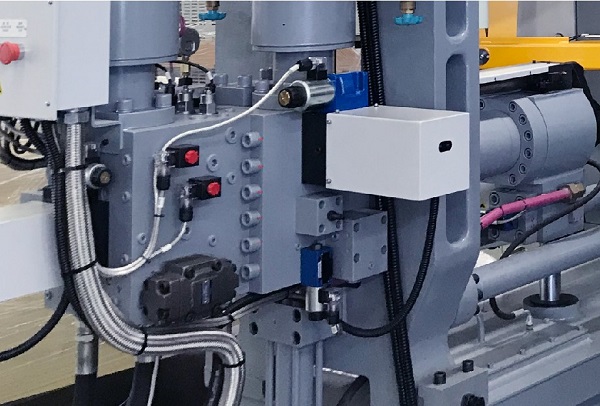

Equip with world-famous, reliable and durable hydraulic components, high-performance and low noise oil pump in order to keep the pressure and rate of flow stable.

Non-contact injection stroke detection, accurate control and high reliability

Large accumulator design, small pressure drop, adequate energy, high injection repetition, fast ramp pressure and speed response, more stable for pressure and speed. Improving the efficiency.

High speed injection, ramp pressure and rate of flow are controlled by the high precision electric proportional valve in the controller. Convenient, stable and save parameter easily .(Small machines are option, big machines are standard)

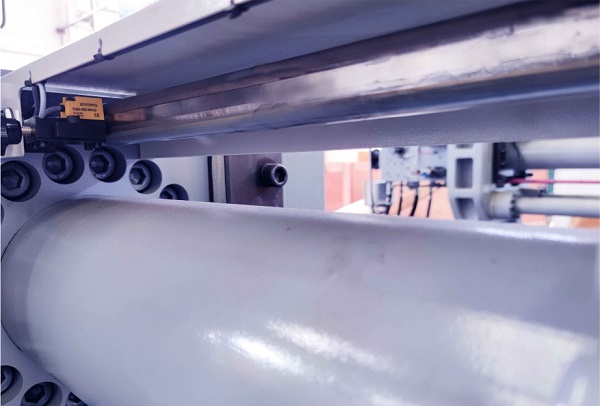

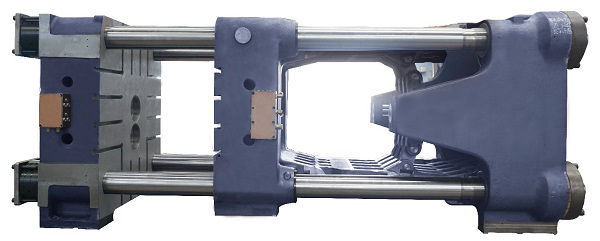

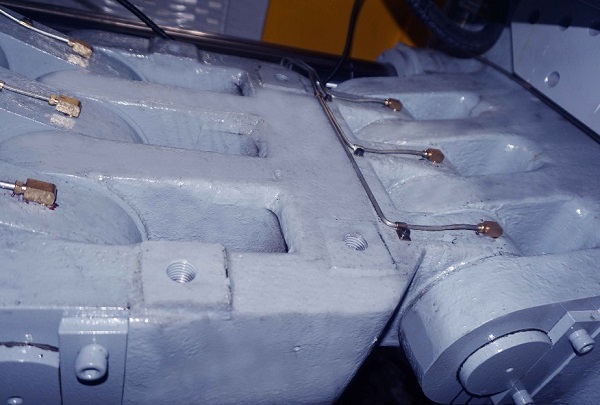

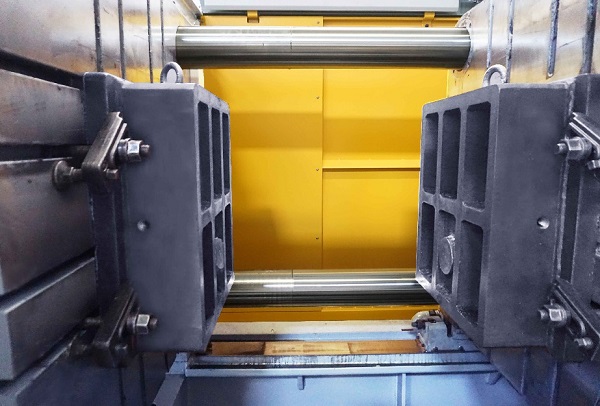

New integrated box type platen, thicker platen design, stronger rigidity, high strength, high stability, durable in impact resistant, longer usage life

Widened toggle and platen hinge ears, the compression will be even so that the chance of bending and deformation can be reduced.

The design of increasing the die height, allowing to accommodate larger die.

Patented high tensile alloy tie bar design, ensure reliable and durable of the clamping system, longer usage life

German Siemens PLC as the main control system, reliable and stable performance

X

X