Lock Seam Forming Machine is used for production customized lock seaming roofing profiles.

Description:

Lockseam Roofing Machine/Seam Lock Foofing Machine/Standing Seam Curving Machine/Seam Lock Profiling Machine/Lock Seam Forming Machine/Electric Seaming Machine:

It can be made as per desired requirements and can be fabricated from various material thicknesses and in almost any length. With highly punching accuracy, notching for light panel, accurate dimension forming automatically and cut to length, the forming line popular used in PEB construction field.

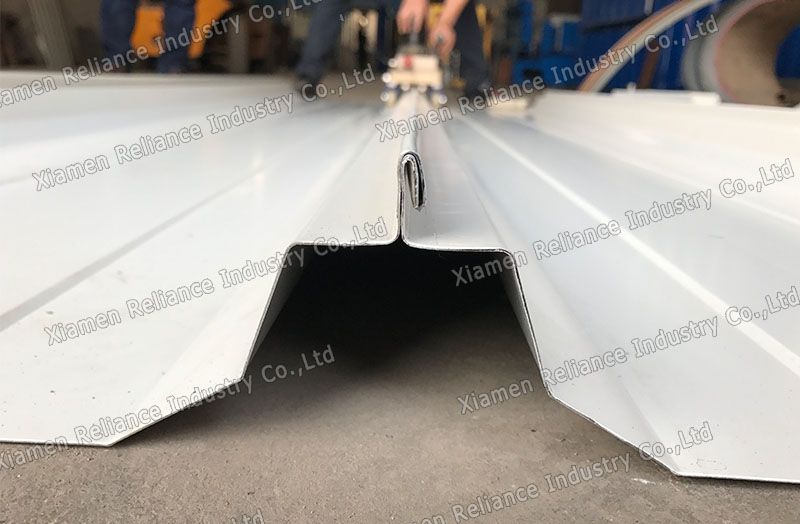

Roofing install with metal clips and seaming together that can get better joint function, no more leakage after years of raining season affect. Machine fix in container and make into portable type can suit for site working purpose, which much highly improve customer working efficiency.

Working Procedure:

Uncoiling– Roll Forming Machine– Cutting– Collecting

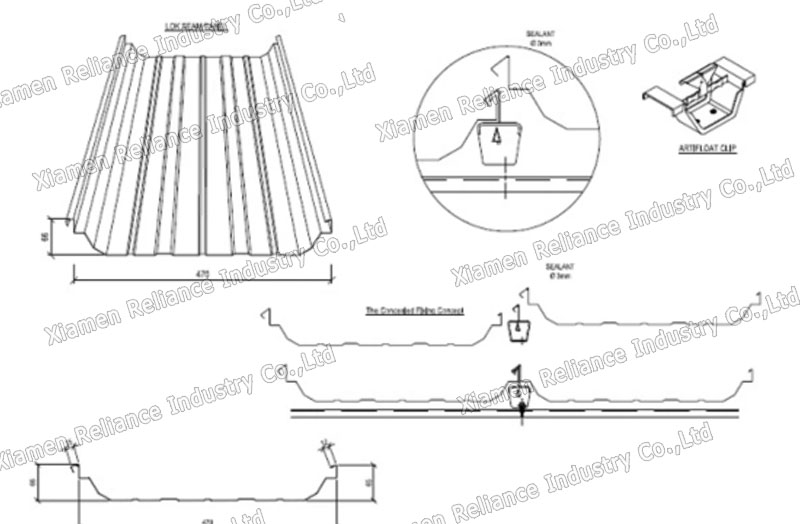

Profile:

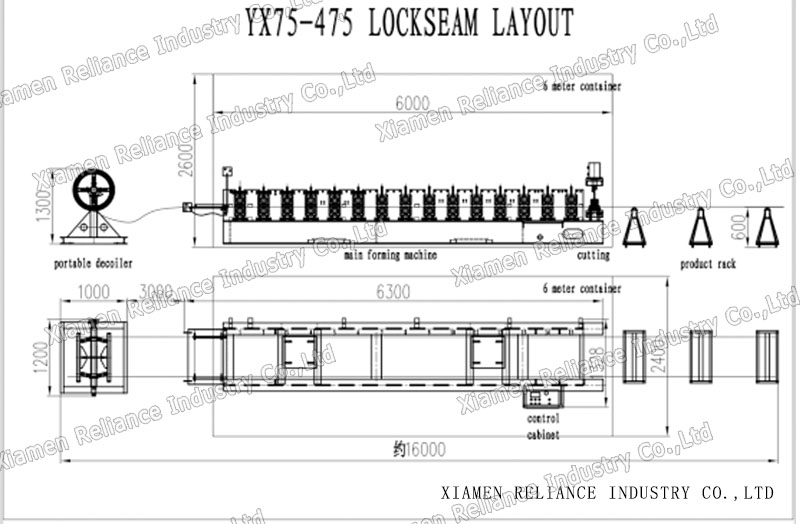

Layout:

Technical Details:

The Line’s Specifications

Weight

About 4600kgs

Whole line’s dimension

About 6m x 1.2m x 1.3m (length x width x height)

Color

Main color: blue

Warning color: yellow

Suitable Raw Material

Material

PPGI, GL, PPGL, ALUMINUM

Thickness

0.4-0.8mm

Coil feeding width

600/610mmm

Cover width

475/480mm

Yield Strength

350~550Mpa

Main Technical Parameters

Quantity of forming rollers stations

About 15

Diameter of forming rollers shafts

75mm

Roll Forming Speed

22m/min

Accessories

One electric seaming machine, two hand pincers

Forming rollers material

40Cr, CNC lathes, hard Chrome Coated

Cutter material

Cr12 mould steel, with quenched treatment

Controlling system

Combined with: PLC (Siemens), Touch Screen (Siemens), Inverter (Schneider), Encoder (Omron), etc

Electric Power requirement

Main motor power: 4kw*2

Hydraulic unit motor power: 4kw

Electric voltage

According to customer’s requirement

Main Components

Decoiler (manual and automatic for options)

1 set

Roll Forming system

1 set

20 feet container

1 unit, modify to site working purpose

Electric seaming machine

1 set

Hand seaming pincers

2 units

PLC control box

1 set

Hydraulic unit

1 set

Run outs tables

1 set

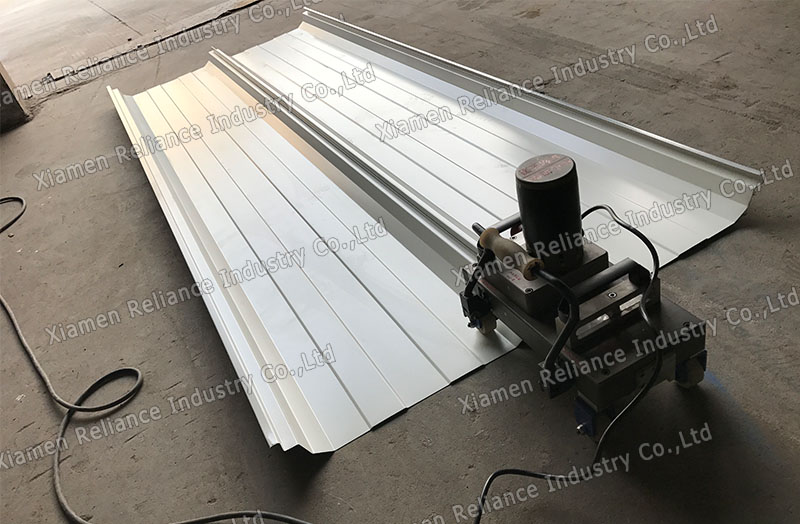

electric seaming machine:

lock seam forming machine:

lock seam seaming machine:

portable seam lock machine:

Loading Photos:

X

X