Sales Manager: Andrea

Email: Andrea@tmaxlaboratory.com

Wechat: 18250801164

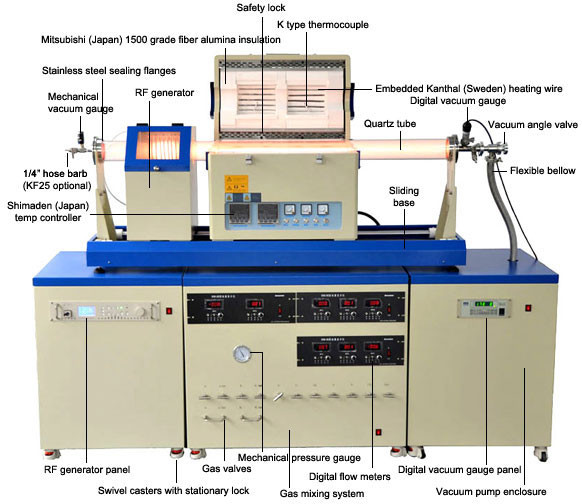

Lab CVD System with 1500-1500C Dual Zone Rotary Tube Furnace

The CVD system consists of gas supply system + tube furnace + vacuum system, and the maximum temperature can reach 1200 degrees, 1400 degrees, 1600 degrees, and 1700 degrees. The heating zone can be single temperature zone, dual temperature zone, three temperature zone, etc. The ultimate vacuum can reach 10-3Pa. The gas supply system can be mass flowmeter or float flowmeter for flow regulation. The number of mixing channels can be 2 channels, 3 channels, 4 channels, and 5 channels.

Detailed technical parameters

|

Model |

1500-1500-I 1500-1500-II |

|

Power |

9KW 9KW |

|

Tube size |

Dia 60(OD) X1400 mm Dia 80(OD) X1400 mm |

|

Supply voltage |

380V 380V |

|

Phase |

dual phase dual phase |

|

Tube |

Corundum tube: high purity AIO ceramics (including) 99.5% |

|

Heating element |

First temperature zone:silicon carbon rod Second temperature zone: silicon carbon rod |

|

Furnace tube rotation speed |

With stepless variable speed motor, the speed can be adjusted between (1-25 RPM) |

|

Motor power |

40W |

|

The furnace can be tilted at an Angle |

0-30degree |

|

Kind of drive |

Toothed belt and gear |

|

Control mode |

UAV program temperature control instrument (standard) 1, 30-stage program temperature control intelligent PID adjustment. 2. With over-temperature protection, the electric furnace heating circuit is automatically cut off when the temperature is over-temperature or broken, (when the electric furnace temperature exceeds 1520 degrees or the thermocouple is blown, the AC relay on the main circuit will be automatically disconnected, the main circuit is broken. On, the ON light on the panel is off, the OFF light is on, and the limited protection electric furnace). 3, with 485 communication interface (standard when purchasing software) 4, with power-off protection function, that is, when the power is turned on after the power is turned off, the program does not start from the starting temperature, but the furnace temperature rises from the time of power failure. 5, the meter has the function of temperature self-tuning

(you need to pay extra for the replacement of imported instruments, optional)

FP93 instrument EUROTHERM instrument Touch screen instrument (shimaden, Japan) |

|

Furnace material

|

1. High quality high purity alumina polycrystalline fiber curing furnace formed by vacuum filtration. 2. Adopt Japanese technology for molding. |

|

Control accuracy |

+/- 1℃ |

|

Trigger |

Phase-shifted trigger |

|

Electric appliance |

Zhejiang chint |

|

Silicon controlled |

106/16ESEMIKRON |

|

The highest temperature in the first and second temperature zones |

1500℃ |

|

Rated temperature in the first and second temperature zones |

1400℃ |

|

Heating rate |

≤20℃/ Min(it can be modified as required) |

|

Recommended rate of temperature rise |

≤10℃/ Min |

|

Thermocouple |

S typein the first temperature zone S typein the second temperature region |

|

Length of heating section in the first and second temperature zones |

300+300mm 300+300mm |

|

Constant temperature length |

450mm 450mm |

Gx-3 three-channel air supply (mixed air) system

1.1. The gas exits the cylinder, is depressurized through a pressure reducing valve, passes through the PTFE tube to the inlet of the gas supply system, and then passes through the mass flow meter to control the gas flow, and then passes through the gas mixing tank and then enters the furnace inlet.

1.2. A pressure gauge is attached to the gas mixing tank, and the pressure gauge display disk and the proton flowmeter controller are installed on the same panel.

1.3. Each gas line has a high pressure shut-off valve for safety.

1.4. The gas path adopts a high-precision gas mass flow meter, and the inside of the gas path is entirely made of stainless steel pipe, which has good corrosion resistance.

1.5. All the joints in the box are connected by stainless steel ferrules, which have good air tightness and high pressure resistance.

2. Technical parameters:

Pneumatic channel: 3

Gas flow control: mass flow meter.

Cabinet dimensions: 600X600X600mm

Mass flowmeter technical parameters:

Interface: Φ6

Display: LED

Working environment temperature: 5~45°C

Flow controller: Proton flow controller parameters Please check back

Stainless steel tube: Φ6 outside X Φ4

Pressure vacuum table: -0.1~0.15 MPa, 0.01 MPa/division

Stop valve: Φ6

Flow control: PLC intelligent control

3. Mass flowmeter technical parameters:

Product Name: Mass Flow Controller

Product Description : Normal type, analog circuit

Product details: Ordinary, analog circuit, rubber seal, tubular shunt, not easy to block.

Main indicators: Range: 5, 10, 20, 30, 50, 100, 200, 300, 500 SCCM, 1, 2, 3, 5, 10 SLM (you can choose the range arbitrarily)

• Accuracy: ±1% F.S

• Linear: 0.5% F.S

• Repeatability: ±0.2% F.S

• Response time: 1S

• Air pressure drop: <0.01MPa

• Maximum pressure: 3MP

• Working environment temperature: 5~45°C

• Input and output signals: 0~+5.00V

• Power: +15V 50mA -15V 50mA

• Dimensions: 158*30*110

• Weight: 0.9 Kgg

4. Configuration of the gas supply system:

1. Proton flowmeter: 3

2. Mechanical pressure gauge (range -0.1~0.15MPa): 1

3. Stainless steel cut-off valve: 4

4. Stainless steel plate joints: 4

5. Stainless steel valve connector: 2

6. Stainless steel cylinder connector: 3

7. PTFE tube: 15M

8. Mixing tank Dia80X140MM: 1

9. Furnace rack: 1 set

VS High Vacuum System

|

Molecular pump unit (Option 1 or option 2)

|

Unit input voltage |

380V /220V |

|

|

Bellows |

KF40X1000 |

||

|

Vacuum baffle valve |

KF40 |

||

|

Dimensions |

600X600X600 |

||

|

molecular pump

(Option 1) |

Model |

FJ620 |

|

|

input voltage |

380V |

||

|

Inlet flange |

DN160 |

||

|

Pumping rate L/S (to air) |

600 |

||

|

ultimate pressure(Pa) |

6×10-7 |

||

|

type of cooling |

water-cooling |

||

|

cooling water pressure(MPa) |

0.1-0.2 |

||

|

cooling water temperature |

<25℃ |

||

|

environment temperature |

0~40℃ |

||

|

Recommended starting pressure |

<100pa |

||

|

Fore-stage vacuum pump TRP-24 of molecular pump (FJ620 molecular pump must be equipped with previous pump) (Option 2

|

功率 |

0.75KW |

|

|

电压 |

380V |

||

|

转速 |

1450rpm |

||

|

· Inlet Diameter |

KF25/KF40 |

||

|

Pumping rate of front engine(L/S) |

6 |

||

|

Ultimate pressure |

4X10 -2Pa |

||

|

Germany Pfeiffer vacuum pump (Option 2)

|

voltage |

220V |

|

|

power |

110W |

||

|

Extraction interface |

KF40 |

||

|

weight |

150KG |

||

|

Pumping speed of front engine |

0.9m 3/ h |

||

|

pumping rate(N2) |

33L/S |

||

|

composite vacuum gages

|

model |

ZDF |

|

|

power supply |

220V 55W |

||

|

control accuracy |

± 1% |

||

|

Vacuum gauge measuring range |

10-5 -10 5 Pa |

||

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

X

X