Automatic High Speed Toilet Paper/ Maxi Roll Rewinding Machine is for toilet paper roll/maxi roll processing.

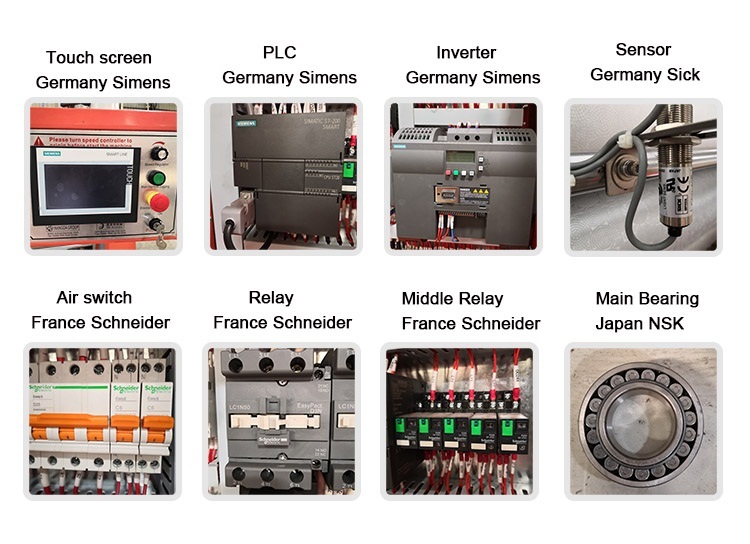

Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

WD-JR-RSM1092-3200IV JRT Big Roll Toilet Paper Rewinding Machine Production Line

Automatic High Speed Toilet Paper/ Maxi Roll Rewinding Machine is for toilet paper roll/maxi roll processing.

Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

X

X