Sales Manager: Andrea

Email: Andrea@tmaxlaboratory.com

Wechat: 18250801164

Overview of Industrial Planetary Ball Mill

Vertical planetary ball mill is a necessary device of high-tech materials mixing, fine grinding, sample making, new product development and small batch production. Tmax planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for R&D institution, university, enterprises laboratory to get samples (each experiment can get four samples at the same time). It gets powder samples under the vacuum state when equipped with vacuum ball mill tank.

Working Principle of Industrial Planetary Ball Mill

Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill with dry or wet method. Minimum granularity of ground powder can be as small as 0.1μm.

Features of Tmax Industrial Planetary Ball Mill

1. Stable revolving speed of the gear transmission ensures the consistency and repeatability of the experiment.

|

Drive Mode |

Gear drive |

|

Operate Mode |

Two or four grinding jars working together |

|

Maximum Loading Capacity |

2/3 of the total volume of milling jars |

|

Feeding Size |

Soil material≤10mm,other materials≤3mm |

|

Output Granularity |

Smallest granule reaches 0.1μm |

|

Rotational Speed Ratio |

1:2 |

|

Max.Continuous Operating Time |

72 Hours |

|

Materials of Jar |

Stainless steel.agate,nylon,corundum,zirconia,etc |

|

Type |

Specification |

Volume of Each Matched Pot |

Qty |

|

XQM-2 |

2L |

50ml-500ml |

4 set |

|

XQM-4 |

4L |

250ml-1L |

4 set |

|

XQM-6 |

6L |

lL-1.5L |

4 set |

|

XQM-8 |

8L |

1L-2L |

4 set |

|

XQM-10 |

10L |

1L-2.5L |

4 set |

|

XQM-12 |

12L |

1L-3L |

4 set |

|

XQM-20 |

20L |

2L-5L |

4 set |

|

XQM-40 |

40L |

5L-10L |

4 set |

|

XQM-60 |

60L |

10L-15L |

4 set |

|

XQM-100 |

100L |

20L-25L |

4 set |

|

Model |

Power supply |

Motor power Converter power |

Operating time setting (min) |

Positive and negative alternating operation time(min) |

Adjustable speed Revolution (rpm) |

Adjustable speed Rotation (rpm) |

Noise <db |

|

XQM-2 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

|

XQM-4 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

|

XQM-6 |

220V 50HZ |

0.75KW |

1-9999 |

1-999 |

30-335 |

70-670 |

60db |

|

XQM-8 |

220V 50HZ |

1.5KW |

1-9999 |

1-999 |

35-290 |

70-580 |

60db |

|

XQM-10 |

220V 50HZ |

1.5KW |

1-9999 |

1-999 |

35-290 |

70-580 |

60db |

|

XQM-12 |

220V 50HZ |

1.5KW |

1-9999 |

1-999 |

35-290 |

70-580 |

65db |

|

XQM-20 |

380V 50HZ |

4KW |

1-9999 |

1-999 |

25-215 |

50-430 |

65-db |

|

XQM-40 |

380V 50HZ |

5.5KW |

1-9999 |

1-999 |

20-195 |

40-390 |

68db |

|

XQM-60 |

380V 50HZ |

7.5KW |

1-9999 |

1-999 |

27-174 |

40-260 |

68db |

|

XQM-100 |

380V 50HZ |

11KW |

1-9999 |

1-999 |

27-160 |

40-240 |

68db |

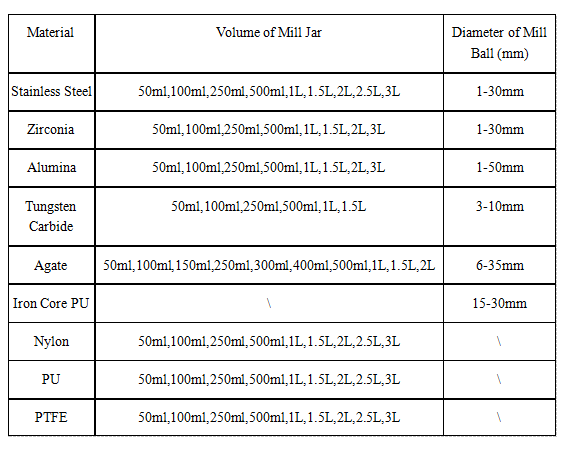

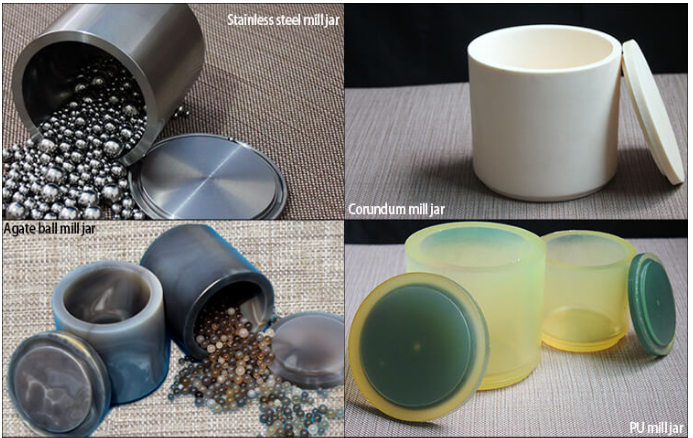

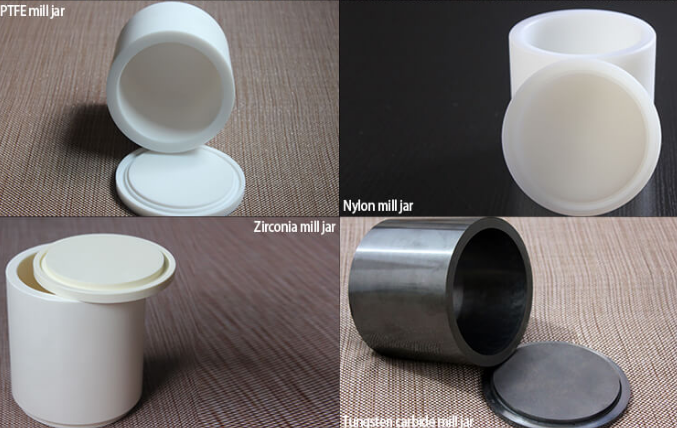

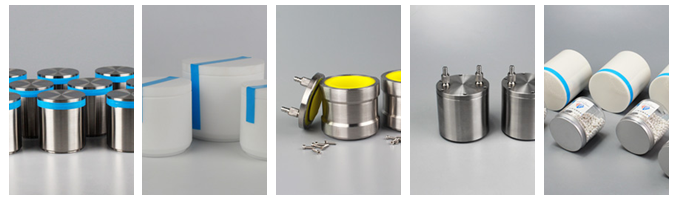

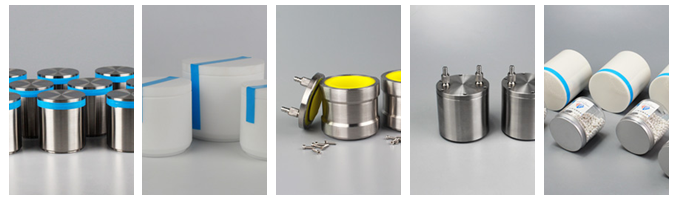

Accessories of Mill Jars & Balls For Industrial Ball Mill

Besides the planetary ball mill machine, our factory provides all kinds of mill pots,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU mill pot, tungsten mill pot, hard metal mill pot and tempered nylon mill pot etc. Further, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

X

X