ZXD Separated Type Water Electrolysis Hydrogen Generation Equipment/System

Technical Specification

Technical Specification

P/N

ZXD-60

ZXD-80

ZXD-100

Hydrogen Production(m3/h)

65

100

120

Oxygen Production(m3/h)

30

40

50

Hydrogen Purity(V/V)

≥99.99%

≥99.99%

≥99.99%

Oxygen Purity(V/V)

≥92.5%

≥92.5%

≥92.5%

Operating load

50%-100%

50%-100%

50%-100%

Working Pressure(MPa)

1.5~2.0

1.5~2.0

1.5~2.0

Hydrogen Moisture Content(g/m3)

≤4

≤4

≤4

Hydrogen Alkalinity(mg/m3)

≤1

≤1

≤1

Working Temperature(℃)

85±5

85±5

85±5

Cooling water flow(m3/h)

9

12

15

DC power consumption(kW·h/m3H2)

≤4.3

≤4.3

≤4.3

External dimension of electrolyzer L×W×H (mm)

2170x1450x1580

2620x1450x1580

2500x1650x1860

Electrolyzer Weight(kg)

7600

8900

14100

Alkali concentration

30% KOH

30% KOH

30% KOH

Circulation quantity of alkali liquor(m3/h)

3.35~4.0

5.6~6.7

6.5~8.0

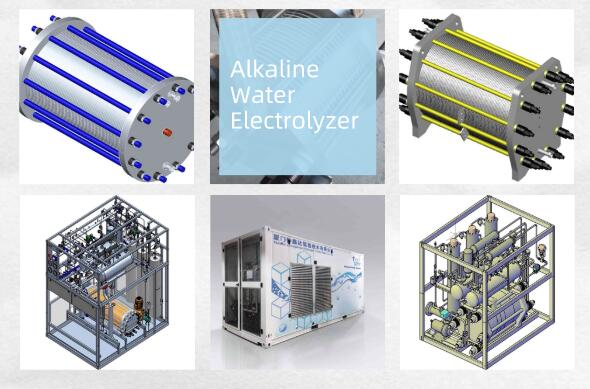

The main products of Zhongxinda also include: hydrogen purification device, oxygen purification device, nitrogen purification device, pressure swing adsorption hydrogen production device, pressure swing adsorption oxygen production device, pressure swing adsorption nitrogen production device, methanol cracking hydrogen production device and pure water device.

According to different site conditions, Zhongxinda has developed a variety of characteristic hydrogen production equipment, such as container-type hydrogen production equipment, skid-mounted hydrogen production equipment, cabinet hydrogen production equipment and so on, to fully meet the different needs of users.

Hydrogen production equipment and gas purification equipment produced by Zhongxinda have been widely used in electric power, electronics, semiconductor materials, optical fiber, metallurgy, building materials, atomic, chemical, aerospace, meteorology, medicine and other industries.

Company Profile

Company Profile

Zhongxinda has the leading alkaline hydrolysis hydrogen production technology in the field of hydrolysis. Our products cover the whole field of electrolyzer, the core component of water electrolysis hydrogen production process, and auxiliary system.

We have accumulated mature technologies in various application scenarios, such as renewable energy, hydrogen production and storage reuse, fixed/skid-mounted hydrogenation stations, by-product hydrogen exhaust hydrogen preparation, standby/emergency hydrogen fuel cell hydrogenation, peak and frequency regulation in thermal power plants and dark green hydrogen microgrid.

We can provide hydrogen production, hydrogen storage and other hydrogen industry chain solutions

Our Advantages

Our Advantages

Certification

Certification

Zhongxinda has passed ISO9001 quality management system certification

Zhongxinda has passed the ISO45001 occupational health system certification

Zhongxinda has passed the ISO14001 occupational health system certification

FAQ

FAQ

X

X