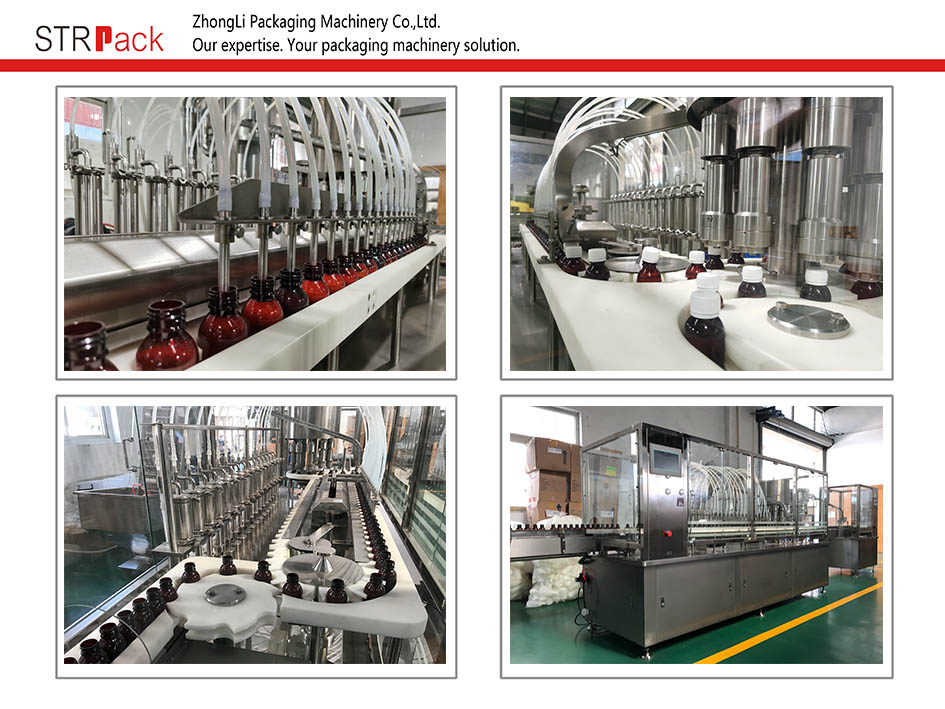

Automatic High Speed Oral Liquid Syrup Filling And Capping Machine

Brief Introduction:

Automatic High Speed Oral Liquid Syrup Filling And Capping Machine works on volumetric principle with syringe & piston & nozzle. It is used to fill liquid in bottle in pharmacy, food, dairy, agro chemicals and Beverages industries.

The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Drives unit with syringe & piston, Reciprocating Nozzle with self-centering devices & No container No filling system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of gear motor with synchronized variable drive.

Features:

Optional Features :

Main Parameter:

|

Model |

Unit |

SMF |

|

Filling volume |

Ml |

5-250 |

|

Production capacity |

Bottle/h |

5000-12000 |

|

Quantitative error |

% |

≤±1% |

|

Cap feeding rate |

% |

≥99% |

|

Capping rate |

% |

≥99% |

|

Source voltage |

V |

Three-phase four-wire system AC220V 380V ±10% |

|

Consumed power |

KW |

5 |

|

Gas supply pressure |

MPA |

0.4-0.6 |

|

Air consumption |

M3/min |

0.5 |

After-sales Service:

(1) Under stable voltage, the machines' quality that we sold will be guaranteed for 2 year

(2) Long time technology will be supplied.

(3) We can dispatch our engineer to your side for installing and debugging machines. Engineer's round-trip tickets, accommodation, and your side traveling fee will be charged by you. Engineer's salary will be USD100.00/day/person.

We can also supply training process for your engineers who come to china, so you can fit and debug machines by yourself.

About Us

--Focusing on Development, Packaging Industry Leader

--Keeping on Recruiting Talents and Innovation

--Advanced equipment, Guaranteed quality

For quick response please contact us by cellphone/ WhatsApp: 008617317720909

X

X