Fluorine lined diaphragm valve is a special form of cut-off valve, appeared in the 1920s.Its opening and closing parts is a diaphragm made of soft material, the valve body cavity and valve cover cavity and drive parts separated, so called diaphragm valve.

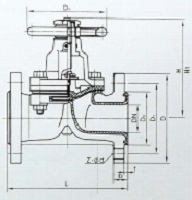

G41F46/J Fluorine lining diaphragm valve

Fluorine lined diaphragm valve is a special form of cut-off valve, appeared in the 1920s.Its opening and closing parts is a diaphragm made of soft material, the valve body cavity and valve cover cavity and drive parts separated, so called diaphragm valve.

The most prominent feature is the diaphragm of the lower body cavity and upper valve cover chamber separated, so that the valve stem above the diaphragm, valve disc and other parts are not corroded by the medium, leaving out the packing seal structure, and will not produce medium leakage.

1, the use of rubber or plastic and other soft sealing diaphragm, good sealing.As the diaphragm is a vulnerable part, it should be replaced regularly according to the characteristics of the medium.

2, by the diaphragm material restrictions, diaphragm valve is suitable for low pressure and temperature is relatively low.

3, according to the structure of the diaphragm valve can be divided into: room type, straight flow, cut-off, straight through, gate type and right-angle type six;The connection form is usually flange connection;According to the driving mode can be divided into manual, electric and pneumatic three, pneumatic drive is divided into normal open, normal closed and reciprocating three.

4. Generally, it should not be used in pipelines with temperature higher than 60 degrees and conveying organic solvents and strong oxidizing media, nor should it be used in pipelines with higher pressure

Nominal pressure:PN1.0~1.6Mpa Nominal diameter:DN15~DN300

|

Main Parts Material |

|||||||||

| No. | Part name | Cast iron |

Cast steel |

Rust - resistant cast steel |

Ultra low carbon stainless steel acid cast steel |

||||

|

Z |

C |

P | R | PL | RL | ||||

| 1 | Body/Bonnet |

HT250 |

WCB |

CF8 | CF8M | CF3 | CF3M | ||

|

2 |

Disc/Stem |

WCB |

1Cr13 |

WCB |

2Cr13 |

1Cr18Ni9Ti |

1Cr18Ni12Mo2Ti |

00Cr18Ni10 |

00Cr17Ni14Mo2 |

|

Carbon steel (surface anti-corrosion treatment) |

Carbon steel (surface anti-corrosion treatment) |

||||||||

| 3 | Liner/Seat |

PCTEF(F3),FEP(F46),PFA(Fusible type F4),PP,PO |

|||||||

| 4 | Diaphragm |

PEP(F46)/CR,PFA/FPDM |

|||||||

| 5 | Stents |

PTFE(F4) |

CF8 |

CF8 |

|||||

| 6 | Stem Nut |

ZCuAl10Fe3 |

ZCuAl10Fe3 |

ZCuAl10Fe3 |

|||||

| 7 | Fastening bolt |

35 |

1Cr17Ni2 |

1Cr18Ni9Ti |

|||||

| 8 | Nut |

45 |

0Cr18Ni9 |

0Cr18Ni9 |

|||||

| 9 | Handwheel |

WCB |

WCB |

WCB |

|||||

| Dimensions,connection size and weight | ||||||||||||

| Nominal diameter | Standard values | Reference | ||||||||||

| DN(mm) | NPS(inch) | L | D | D1 | D2 | f | b | z-φd | Do | H | H1 | WT(kg) |

| PN 0.6 Mpa | ||||||||||||

| 15 | 1/2 | 124 | 80 | 55 | 40 | 2 | 12 | 4-12 | 100 |

|

80 | 1.6 |

| 20 | 3/4 | 135 | 90 | 65 | 50 | 2 | 14 | 4-12 | 100 |

|

90 | 2.4 |

| 25 | 1 | 150 | 100 | 75 | 60 | 2 | 14 | 4-12 | 120 |

|

100 | 3.4 |

| 32 | 1 1/4 | 160 | 120 | 90 | 70 | 2 | 16 | 4-14 | 120 |

|

110 | 4.8 |

| 40 | 1 1/2 | 180 | 130 | 100 | 80 | 3 | 16 | 4-14 | 140 |

|

120 | 6.0 |

| 50 | 2 | 210 | 140 | 110 | 90 | 3 | 16 | 4-14 | 160 |

|

135 | 8.8 |

| 65 | 2 1/2 | 250 | 160 | 130 | 110 | 3 | 16 | 4-14 | 200 |

|

145 | 11.5 |

| 80 | 3 | 300 | 185 | 150 | 125 | 3 | 18 | 4-18 | 200 |

|

180 | 15.2 |

| 100 | 4 | 350 | 205 | 170 | 145 | 3 | 18 | 4-18 | 280 |

|

195 | 18.8 |

| 125 | 5 | 400 | 235 | 200 | 175 | 3 | 20 | 8-18 | 320 |

|

210 | 22.5 |

| 150 | 6 | 460 | 260 | 225 | 200 | 3 | 20 | 8-18 | 400 | 200 | 450 | 48 |

| 200 | 8 | 570 | 315 | 280 | 255 | 3 | 22 | 8-18 | 400 | 200 | 490 | 65 |

| 250 | 10 | 680 | 370 | 335 | 310 | 3 | 24 | 12-18 | 500 | 240 | 550 | 88 |

| 300 | 12 | 790 | 435 | 395 | 362 | 4 | 24 | 12-23 | 500 | 280 | 600 | 125 |

| 350 | 14 | 900 | 485 | 445 | 412 | 4 | 26 | 12-23 |

|

280 | 675 | 185 |

| 400 | 16 | 1000 | 535 | 495 | 462 | 4 | 28 | 16-23 |

|

320 | 780 | 255 |

| 450 | 18 | 1092 | 590 | 550 | 518 | 4 | 28 | 16-23 |

|

360 | 820 | 320 |

| 500 | 20 | 1194 | 640 | 600 | 568 | 4 | 30 | 16-23 |

|

360 | 910 | 405 |

| Dimensions,connection size and weight | ||||||||||||

| Nominal diameter | Standard values | Reference | ||||||||||

| DN(mm) | NPS(inch) | L | D | D1 | D2 | f | b | z-φd | Do | H | H1 | WT(kg) |

| PN 1.0 Mpa | ||||||||||||

| 15 | 1/2 | 124 | 95 | 65 | 45 | 2 | 14 | 4-14 | 100 | 105 | 110 | 3.5 |

| 20 | 3/4 | 135 | 105 | 75 | 55 | 2 | 16 | 4-14 | 100 | 115 | 125 | 4 |

| 25 | 1 | 150 | 115 | 85 | 65 | 2 | 16 | 4-14 | 120 | 120 | 135 | 5.5 |

| 32 | 1 1/4 | 160 | 135 | 100 | 78 | 2 | 18 | 4-18 | 120 | 125 | 150 | 8 |

| 40 | 1 1/2 | 180 | 145 | 110 | 85 | 3 | 18 | 4-18 | 140 | 135 | 175 | 11 |

| 50 | 2 | 210 | 160 | 125 | 100 | 3 | 20 | 4-18 | 160 | 155 | 195 | 14 |

| 65 | 2 1/2 | 250 | 180 | 145 | 120 | 3 | 20 | 4-18 | 200 | 170 | 200 | 23 |

| 80 | 3 | 300 | 195 | 160 | 135 | 3 | 22 | 4-18 | 200 | 200 | 255 | 29 |

| 100 | 4 | 350 | 215 | 180 | 155 | 3 | 22 | 8-18 | 280 | 270 | 325 | 46 |

| 125 | 5 | 400 | 245 | 180 | 185 | 3 | 24 | 8-18 | 320 | 335 | 405 | 70 |

| 150 | 6 | 460 | 280 | 210 | 210 | 3 | 24 | 8-23 | 400 | 370 | 450 | 95 |

| 200 | 8 | 570 | 335 | 240 | 265 | 3 | 26 | 8-23 | 400 | 480 | 600 | 170 |

| 250 | 10 | 680 | 390 | 350 | 320 | 3 | 28 | 12-23 | 500 | 545 | 620 | 270 |

| 300 | 12 | 790 | 440 | 400 | 368 | 4 | 28 | 12-23 | 500 | 585 | 680 | 320 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway,normally, we are able to make sure the delivery will not exceed 45 days.

X

X