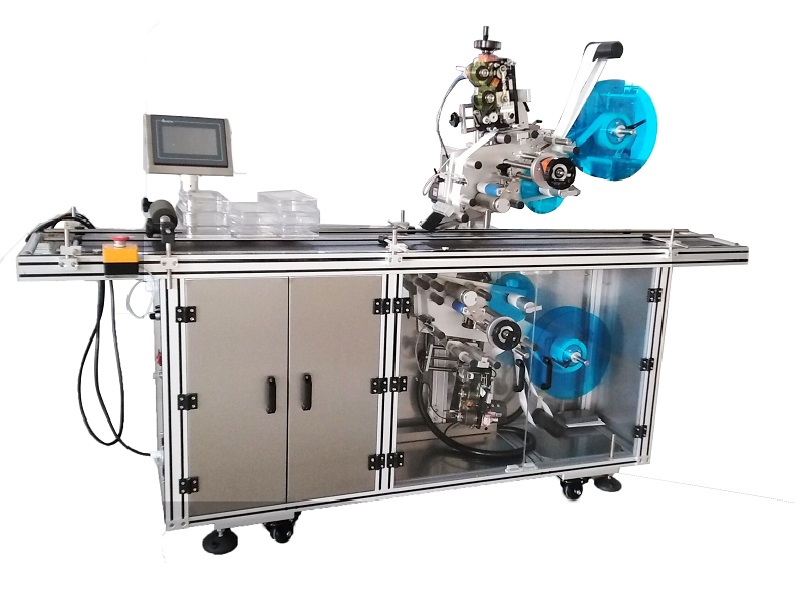

EPL-829 automatic Top&Bottom Flat Surface Labeling Machine For Box/Carton/Paper Sheet, Bag/Pouch, Bottle/Jar/Can/Tin etc.

■ Widely used in food, medicine, daily chemical, electronic, metal, plastics and other industries labeling request.

■ Customized with your labeling requirements.

Fully automatic labeling machines are used in automated production lines with high production volumes. An integration into existing production lines - both hardware and software - should be possible. If a high cycle rate of the production line is required, fully automated labeling of the products and packaging is necessary. Fully automatic labeling systems are less personnel-intensive.

Automatic Top and Bottom Flat Surface Labeling Labeling Machine

Automatic Top & Bottom sides Labeling Machine can work for all kinds of objects with flat surface, side surface, regular rectangles, square shape such as bags, paper, pouch, card, books, boxes, jar, cans, tray etc. To finish top and bottom labeling, two labeling machine can work at the same time. It has optional date coding device, realize date coding on stickers.

CHARACTERISTICS

1.Features

2.After-sale service

After the warranty period, we continue to provide lifetime maintenance services.

Main electrical configuration

(Remark: The configuration will base on the materials condition to adjust it into the same level’s configuration and we also can accord customers’ requirement to revise).

Main Electric Configuration

No.

Name

Q’ty

Brand

Origin

Remark

1

PLC

1

Delta

Taiwan

2

Touch screen 7 inch color

1

Delta

Taiwan

3

Stepping motor

1

Leisai

China

4

Driver

1

Leisai

China

5

Label detection electric eye

1

SICK

Germany

non-transparent label

6

Switching power supply

1

Meanwell

Taiwan

7

Conveyor motor

1

Lijia

China

8

Frequency Inverter

1

Delta

Taiwan

9

Reduction gearbox

1

Funeng

China

10

Optical Fibers

1

SICK/PANASONIC

Germany/Japan

11

Optical Fiber amplified

1

SICK/PANASONIC

Germany/Japan

12

Transparent label detection electric eye

1

Leuze

Germany

Need consider cost difference

13

Key pressing switch

1

Schneider

France

14

Leakage switch

1

CHNT

China

TECHNICAL SPECIFICATIONS

|

Model |

EPL-829 |

|

Accuracy |

±1mm (excluding product and label error) |

|

Labeling speed |

0~150pcs/min(Related to product, label size) |

|

Application |

Apply to Round, flat and square bottles |

|

Application product size |

Length:50-400mm; Width:30-300mm; Height:15-100mm; |

|

Applicable label size |

Length: 20mm~250mm Width(Body paper width): 20mm~110mm |

|

Environment temperature/humidity |

0-50℃/15-85% |

|

Machine Size(L×W×H) |

2350mm×980mm×1350mm(L*W*H) |

|

Voltage |

220V/50/60Hz |

Applications

Top and bottom labeler is widely used in cosmetics , food , medicine , daily chemicals , electronics , toys , hardware , plastics and other industries , and can be applied to many differnet kinds of products that need label on top and bottom two sides, such as boxs,bags, jars ,bottles,cans caontainer and so on; and the machine has the advantages of high stability , good labeling effect , no air bubbles , no wrinkles and accurate labeling.

X

X