Floor Decking Roll Forming Machine is Easy to operate and keep stable.

Please Click Here to View the Video

YX76-960 Floor Deck Roll Forming Machine

1. Advantages:

1) The Floor Deck Roll Forming Machine produced by BMS has the characteristics of low, light weight and high strength

2)Save materials and do not waste.

3)Simple operation and low maintenance cost

2. Machine Components

Machine Order

1) Pre-cutter

Brand: BMS Original: China

It is only used to cut the first and last pieces of the sheet. Easy to operate and save materials.

The pre-cutting knife is connected to the PLC control system, and the PLC calculates the length of the profile during the roll forming.

The movement requires refueling, and the PLC calculates the length and reminds the operator,

After completion, the material can be cut manually before the rolling production molding, which is easy to replace

New products, advanced functions, saving materials, and no waste.

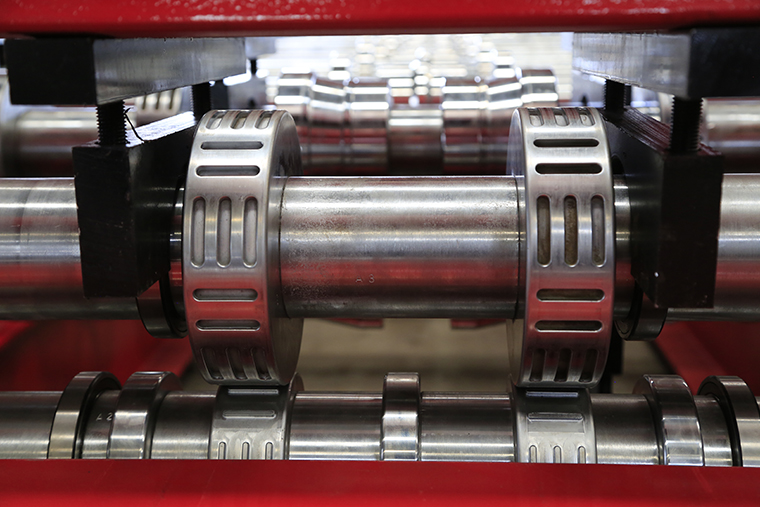

2)Main Forming Mill

The rollers are made of high-quality 45# steel and are heat-treated on a lathe.

Use 400#H-shaped steel welded parts Embossing roller material: bearing steel GCr15, heat treatment

3)Cutting Device

Made of high-quality Cr12 through mold heat treatment

The tool post adopts high-quality 20mm steel plate welded hydraulic

Hydraulic motor: 5.5K, hydraulic range: 0-16Mpa

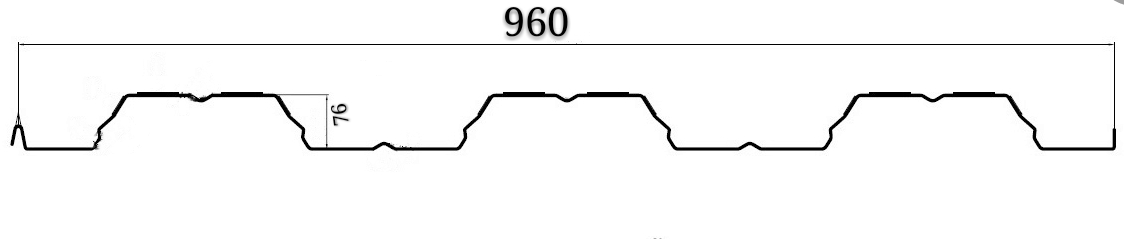

4)Profile Drawing & Product Show

5)Decoiler

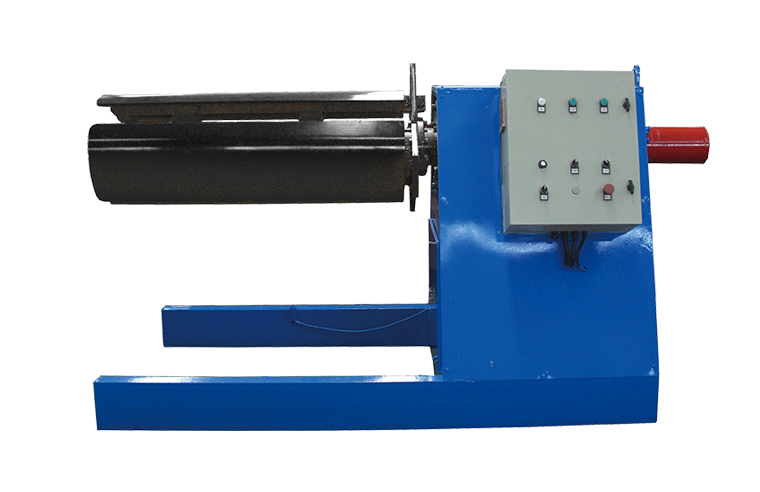

Manual Decoiler

Un-power,Manually control the shrinkage and stop of the inner hole of the steel coil

Maximum. Feeding width: 1200 mm, coil inner diameter range 508 mm ± 30 mm

Capacity: 5-9 tons

Combined with 6 tons hydraulic decoiler (with or without coil)

More Details

Suitable for materials with a thickness of 0.8-1.5mm

The shaft is made of 45#, shaft diameter = φ90mm, precision

Motor drive, gear chain drive, 22-step to form.

Main motor=18.5KW,

Forming speed is about 12-15m/min

PLC control system (touch screen brand: German Schneider Electric/Taiwan WEINVIEW)

Inverter Brand: Taiwan DELTA/SHILIN, Encoder Brand: Japan Koyo/OMRON

Fixed length tolarence: ≤±2 mmWe can send our technicians to install and train the workers in the clients' factories with extra cost

After-Sale Service

1. The warranty is 24 months after the client receives the machine. Within the 24 months, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories with extra cost.

Terms Of Trade

1.Minimum order quantity (MOQ): 1 Set

2.Delivery time: about 45 workdays

3.Port of loading: port of Xiamen

4.Type of payment: by T/T or by L/C

5.Export:to more than 80 countries and regions, including South Korea, Taiwan, UK, Australia, USA, Mexico, Brazil, Russia, Saudi Arabia, UAE, Iran, India, Singapore, Malaysia, Thailand, Indonesia, Philippines, Vietnam, South Africa, Nigeria, Egypt. With us your money in safe, Your Business in Safe.

X

X