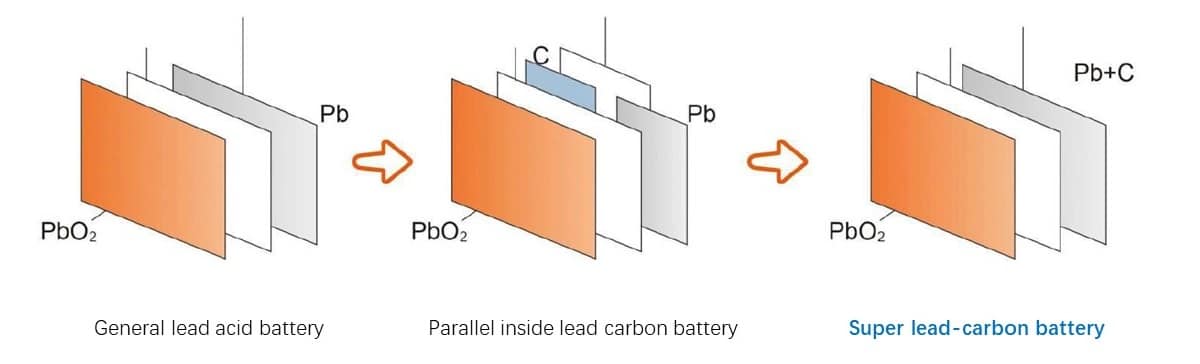

HDC series lead-carbon batteries use functional activated carbon and graphene as carbon materials, which are added to the negative plate of the battery to make lead carbon batteries have the advantages of both lead-acid batteries and super capacitors. It not only improves the ability of rapid charge and discharge, but also greatly prolongs the battery life. It is more suitable for the application of PSOC.

CHARACTERISTICS

CSBattery HDC SERIES Fast Charge DEEP CYCLE Lead Carbon BATTERY

> Why the market need Lead Carbon battery

The most common failure modes are:

– Softening or shedding of the active material. During discharge the lead oxide (PbO2) of the positive plate is transformed into lead sulfate (PbSO4), and back to lead oxide during charging. Frequent cycling will reduce cohesion of the positive plate material due to the higher volume of lead sulfate compared to lead oxide.

– Corrosion of the grid of the positive plate. This corrosion reaction accelerates at the end of the charge process due to the, necessary, presence of sulfuric acid.

– Sulfation of the active material of the negative plate. During discharge the lead (Pb) of the negative plate is also transformed into lead sulfate (PbSO4). When left in a low state-of-charge, the lead sulfate crystals on the negative plate grow and harden and form and impenetrable layer that cannot be reconverted into active material. The result is decreasing capacity, until the battery becomes useless.

Ideally, a lead acid battery should be charged a rate not exceeding 0,2C, and the bulk charge phase should be followed by eight hours of absorption charge. Increasing charge current and charge voltage will shorten recharge time at the expense of reduced service life due to temperature increase and faster corrosion of the positive plate due to the higher charge voltage.

Replacing the active material of the negative plate by a lead carbon composite potentially reduces sulfation and improves charge acceptance of the negative plate.

> Features for Fast Charge Deep Cycle Lead Carbon battery

> Advantages for Fast Charge Deep Cycle Lead Carbon battery

Tests have shown that our lead carbon batteries do withstand at least eight hundred 100% DoD cycles.

The tests consist of a daily discharge to 10,8V with I = 0,2C₂₀, followed by approximately two hours rest in discharged condition, and then a recharge with I = 0,2C₂₀.

≥ 2500 cycles @ 60% DoD (discharge during three hours with I = 0,2C₂₀, immediately followed by recharge at I = 0,2C₂₀)

≥ 3700 cycles @ 40% DoD (discharge during two hours with I = 0,2C₂₀, immediately followed by recharge at I = 0,2C₂₀)

> Construction for Fast Charge Deep Cycle Lead Carbon battery

CSBattery Lead Carbon Tech USE Three generations of technology Of Lead-Carbon Plates.

CSBattery Lead Carbon Tech USE Three generations of technology Of Lead-Carbon Plates.

> Applications for Fast Charge Deep Cycle Lead Carbon battery

> HDC Delivery time

X

X