Alkaline Water Electrolysis Hydrogen Production

P/N

ZXD-470

ZXD-500

ZXD-550

ZXD-600

Hydrogen Production(m3/h)

470

500

550

600

Oxygen Production(m3/h)

235

250

275

300

Hydrogen Purity(V/V)

≥99.99%

≥99.99%

≥99.99%

≥99.99%

Oxygen Purity (V/V)

≥98.5%

≥98.5%

≥98.5%

≥98.5%

Operating load

50%-100%

50%-100%

50%-100%

50%-100%

Working Pressure(MPa)

1.5~2.0

1.5~2.0

1.5~2.0

1.5~2.0

Hydrogen Moisture Content (g/m3)

≤4

≤4

≤4

≤4

Hydrogen Alkalinity(mg/m3)

≤1

≤1

≤1

≤1

Working Temperature(℃)

85±5

85±5

85±5

85±5

Cooling water flow(m3/h)

72

76

83

92

DC power consumption

≤4.3

≤4.3

≤4.3

≤4.3

External dimension of electrolyzer

4720x2325x2750

4750x2325x2750

5160x2325x2750

5520x2325x2750

Electrolyzer Weight (kg)

36100

36600

38900

41400

Alkali concentration

30% KOH

30% KOH

30% KOH

30% KOH

(kW·h/m3H2)

L×W×H (mm)

Technical features of H2 generator by water electrolysis.

Our Service Team

Available to clients around the world,

our flexible service department helps with:

Each service agreement can be tailored to the customer so businesses only pay for the services they need, safe in the knowledge that they can count on their hydrogen supply

Customers rely on our state-of-the-art equipment.

They expect the highest standards of hydrogen quality, reliability and safety from electrolysers that will last.

As with any complex machine, regular maintenance is essential to uphold these standards. We provide a detailed maintenance schedule with each electrolyser, so owners know what to check for each day and how to carry out essential periodic tasks

Even so, we know that owners sometimes need extra support. A service team of experienced engineers is ready to assist our customers in the day-to-day operation to keep your equipment performing at its best

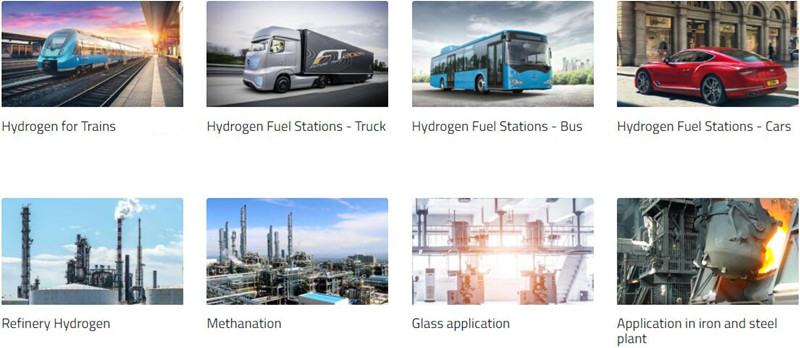

Application:

• Redundant renewable energy transformation and storage

• Lab experiment and teaching

• Laboratory analytic instrument

• Hydrogen healthy care industrial

• Hydrogen beauty industrial

• Fuel for special field

• Hydrogen supply for fuel cell

• Other pure H2 application field

Certification

X

X