Cone crusher is suitable for metallurgy, building materials, mining, chemical and other industries. It can perform medium and fine crushing operations on iron ore, copper ore, limestone, quartz, granite, sandstone and other medium and medium hardness materials. The type of the crushing cavity is determined by the use of the ore. The standard type is used for medium crushing; the medium type is suitable for medium and fine crushing; the short head type is suitable for fine crushing. The machine has the characteristics of reliable structure, high production efficiency, convenient adjustment, and economical use.

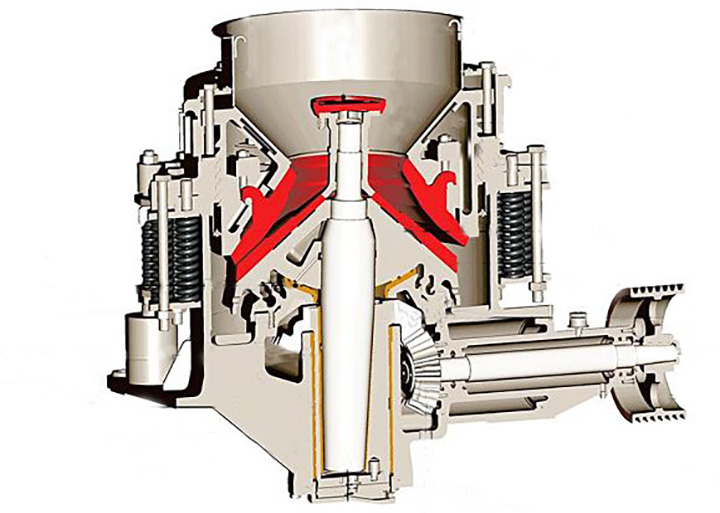

Working principles:

When the composite cone crusher working, the motor drives the eccentric sleeve to rotate via the belt, a big belt wheel,transmission shaft, bevel gear, bevel gear. Crushing cone axis swining under the force of the eccentric sleeve, the surface of broken wall sometimes close to and sometimes leave the rolling mortar wall surface. Material impact, extrusion, bending and crushing, in a ring crushing cavity of the fixed cone and moving cone. After repeated extrusion, impact and bending, material crushing to the required size, discharge from the outlet.

Performance characteristics:

1. Large crushing force, high efficiency, high throughput, low action cost, convenient adjustment, and economical use.

2. Specially designed main shaft structure withstands large crushing and impact forces.

3. The special configuration of stroke, wobble frequency and crushing cavity shape can realize the optimization of the machine capacity.

4. High cubic product content.

5. Hydraulically adjust the size of the discharge port, which is convenient for remote control of product size, saving labor and trouble.

6. The use of arc bevel gears makes the equipment run more stable, with less noise and higher transmission efficiency.

The main technical parameters:

|

Model |

Max Feeding Size(mm) |

Output Size(mm) |

Power (kw) |

Capacity(t/h) | Weight(kg) | ||||||||||

| 6 | 10 |

13 |

16 | 19 | 22 | 25 | 38 | 51 | 64 | ||||||

|

SC600 |

C |

95 |

10 |

37-45 |

|

20 |

25 | 30 | 35 | 45 | 50 | 76 |

|

|

5300 |

| M |

2 |

6 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 60 |

|

|

5300 | ||

| SC1000 | C |

160 |

13 |

90-110 |

|

|

80 |

100 | 135 | 150 | 175 | 235 |

|

|

10800 |

| M |

115 |

10 |

|

65 |

75 | 90 | 120 | 135 | 150 |

|

|

|

10800 | ||

| F |

80 |

8 |

52 |

60 | 72 | 78 | 115 |

|

|

|

|

|

10510 | ||

| EF |

50 |

6 |

50 |

55 | 56 | 70 | 102 |

|

|

|

|

|

10510 | ||

|

SC1160 |

C |

180 |

13 |

110-132 |

|

|

115 |

135 | 150 | 180 | 200 | 260 |

|

|

15500 |

| M |

130 |

10 |

|

100 | 110 | 120 | 135 | 165 | 175 |

|

|

|

15500 | ||

| F |

90 |

10 |

|

80 | 105 | 110 | 140 |

|

|

|

|

|

15500 | ||

| EF |

60 |

6 | 60 | 74 | 105 | 110 | 130 |

|

|

|

|

|

15500 | ||

| SC1300 | C |

200 |

16 |

132-160 |

|

|

|

150 | 180 | 200 | 230 | 310 | 390 |

|

22300 |

| M |

150 |

13 |

|

|

155 | 140 | 160 | 190 | 210 |

|

|

|

22300 | ||

|

F |

102 |

10 |

|

90 | 115 | 145 | 160 |

|

|

|

|

|

22300 | ||

|

EF |

70 | 8 |

|

88 | 110 | 135 | 155 |

|

|

|

|

|

22300 | ||

| SC1380 | C | 215 | 19 |

185-220 |

|

|

|

|

200 | 220 | 260 | 350 | 440 |

|

26300 |

| M | 160 | 16 |

|

|

|

155 | 180 | 200 | 220 |

|

|

|

26300 | ||

| F | 76 | 13 |

|

|

150 | 190 | 210 | 230 |

|

|

|

|

26300 | ||

| EF | 115 | 8 |

|

122 | 148 | 185 | 200 |

|

|

|

|

|

26300 | ||

|

SC1500 |

C | 235 | 22 |

185-220 |

|

|

|

|

|

265 | 310 | 420 | 525 | 580 | 37750 |

| M |

175 |

19 |

|

|

|

|

215 | 240 | 265 | 320 |

|

|

37750 | ||

|

F |

130 |

13 |

|

|

180 | 210 | 235 | 255 | 275 |

|

|

|

37750 | ||

| EF |

90 |

10 |

|

148 | 178 | 200 | 220 |

|

|

|

|

|

37550 | ||

|

SC1600 |

|

267 |

22 |

250-300 |

|

|

|

|

|

330 | 390 | 525 | 655 | 725 | 44300 |

|

|

203 |

16 |

|

|

|

230 | 270 | 300 | 330 |

|

|

|

44300 | ||

|

|

140 |

13 |

|

185 | 225 | 265 | 340 |

|

|

|

|

|

44300 | ||

|

|

95 |

10 |

|

180 | 220 | 260 | 335 |

|

|

|

|

|

44300 | ||

X

X