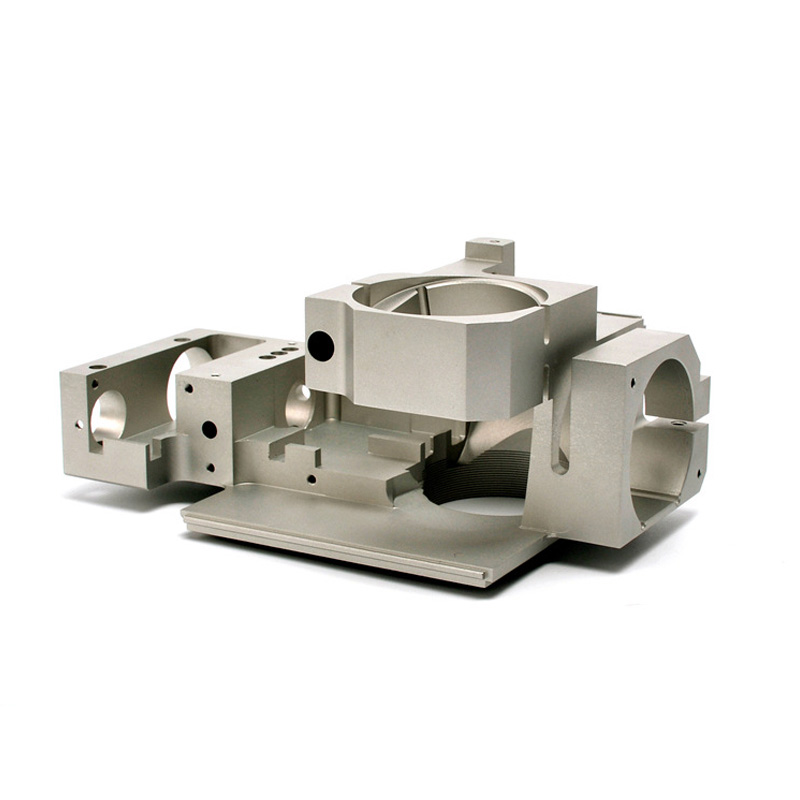

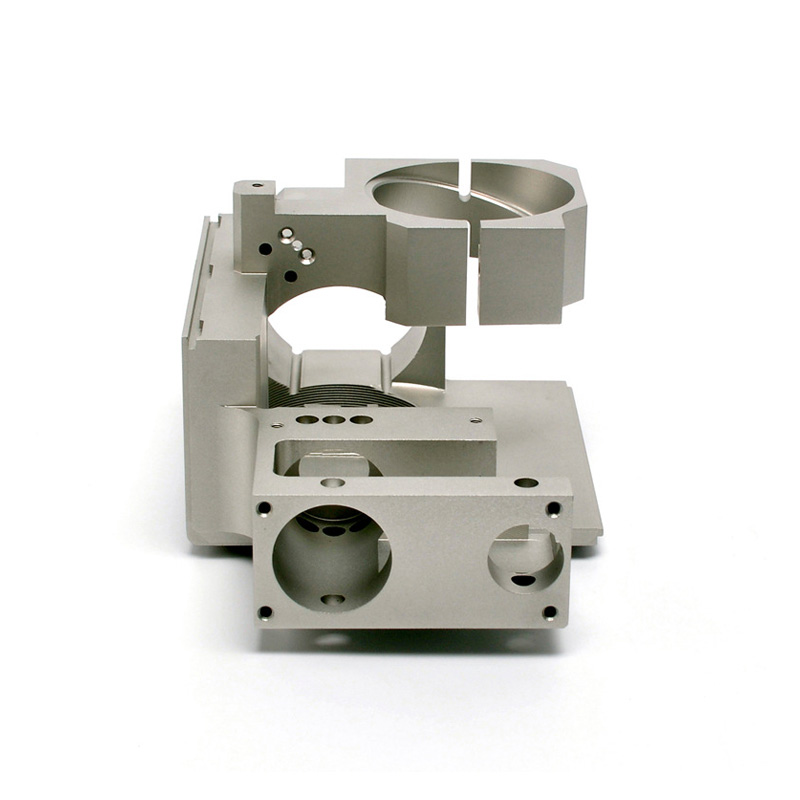

√ Precision CNC machining titanium alloy

√ Various of metal/plastic/FR4/G10 machined services

√ 5 axis / 4axis / 3axis CNC Machining

√ Surface treatment could be customized

√ Upload your own CAD/3D file for a fast quote

Titanium alloy CNC machining services

Titanium alloys are metals that contain a mixture of titanium and other chemical elements.It is hard and lightweight, resistant to erosion, and has high tensile strength and toughness.

Titanium alloy also has good biocompatibility, high chemical stability and excellent mechanical properties in physiological environment, so it is the most commonly used metal biomaterial for medical implants.

JY Machinery offer custom and complete solutions.We specialize in the production of various high precision CNC lathe parts and CNC milling parts, according to customer drawings or samples. If you are interested in our services,Inquiry now!

Our Manufacturing Services:

|

Item Name |

Titanium alloy CNC machining Parts Service |

|

Available materials |

Titanium,Aluminum, Steel, Stainless Steel, Brass, Copper, Bronze, Nylon, POM, ABS, etc |

|

Tolerance |

0.005mm~0.1mm |

|

Surface Roughness |

Ra 0.8-Ra3.2 |

|

DRW format |

.jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

|

Equipment |

CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, polishing machine etc. |

|

Capacity |

10,000pieces per month |

|

MOQ |

No limitation |

|

QC System |

100% inspection before shipment |

|

Payment term |

T/T, PayPal, West Union,etc |

|

Other services |

CNC engrave, Laser engrave, silk printing, Knurling |

|

Shipment Terms: |

1) 0-500kg: air freight priority |

|

2) >500kg: sea freight priority |

|

|

3) As per customized specifications |

|

|

Packing |

1. Prevent from damage. |

|

2. Foam and paper box or wooden box. |

|

|

3. As to customers' requirements, in good condition |

|

|

Lead time |

15~25 days, as to your quantity |

Surface Treatments:

|

Finish Result |

|

|

As Machined |

Sharp edge and burrs will be removed |

|

Bead Blast |

The part surface is left with a smooth, matte appearance |

|

Anodized |

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. |

|

Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. |

|

|

Powder Coat |

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic. |

|

Customized |

Cotact us via email,skype,whatsapp. We will look into a finishing process for you. |

Why choose us:

We have been working on CNC parts processing and rapid prototyping for over 10 years.We have an excellent mechanical design, CNC programming, manufacturing and quality control team.Our company enjoys a good reputation among our clients in America, Europe and Austria.

We offer 24 * 7 online customer service.We manufacture non-standard parts according to your drawings.And we offer the best after-sales service.

Our prices compare favorably with those of other manufacturers.

We have strict quality control from production to delivery.Our company has strong technical support.We have cultivated a group of managers who are familiar with product quality and good at modern management concepts.

Check your homework carefully

1. We have special quality control testers to check product quality according to different customers.

2. We have IQC to check the size and surface of the feed.

3. We have PQC to check the whole process in the process

4. We have FQC to inspect all electroplating products from the outside and conduct 100% inspection before delivery.

We are willing to provide samples for quality and functional testing.We are an ISO 9001:2015 certified company.Our products are superior in quality and reasonable in price.

FAQ:

Q:Do you make customized products based on our design drawings?

A: Yes. Nearly all our products are customized. We are a professional CNC fabrication factory with an experienced engineering team to make custom products according to clients' drawings.

Q: What is the MOQ?

A: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standards.

Q: Is it possible to know how my products are going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: How to deal with the parts received when they are found to be in poor quality?

A:Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs borne by our company.

X

X