XUVAL centric butterfly valves with fixed liner feature an outstanding seating concept. The rubber is injection molded directly on the valve body forming a permanent bond. Consequently, there is no risk of deformation or dislocation of the liner making the valves suitable under vacuum conditions. The combination of the profiled disc edge and the excellent XUVAL rubber quality ensures maximum durability of the liner.

Cast iron lug butterfly valve

Cast iron lug butterfly valve, also known as flip plate valve, is a simple structure of the regulating valve, can be used for low pressure pipe medium switch control butterfly valve refers to the closing part (disc or butterfly plate) as a disc, rotating around the valve shaft to achieve the opening and closing of a valve. Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. It mainly acts as cutting and throttling on the pipeline. Butterfly valve opening and closing is a disc-shaped butterfly plate, in the body around its own axis rotation, so as to achieve the purpose of opening and closing or adjustment.

Characteristics

1. Cast iron lug butterfly valve has the characteristics of simple structure, small volume, light weight, less material consumption, small installation size, fast switch ,90° reciprocating rotation, small driving torque and so on. it is used to cut off, turn on and adjust the medium in the pipeline. it has good fluid control characteristics and close sealing performance.

2. Butterfly valve can transport mud, at the pipe mouth accumulated the least liquid. low pressure, can achieve good sealing. good adjustment performance.

3. butterfly plate streamline design, so that fluid resistance loss is small, it is an energy-saving product.

4. stem is a through rod structure, after tempering treatment, has good comprehensive mechanical properties and corrosion resistance, scratch resistance. When the butterfly valve is opened and closed, the stem is operated only by rotating motion but not by lifting. Fixed with the butterfly plate cone pin, the outer extension end is anti-out-type design, so as not to break out the stem when the valve stem and butterfly plate joint accidentally.

5. connection mode has flange connection, pair clamp connection, butt welding connection and lug pair clamp connection. The driving forms are manual, worm gear transmission, electric, pneumatic, hydraulic, electro-hydraulic linkage and other actuators, which can realize long-distance control and automatic operation.

Advantages

1. opening and closing is convenient and quick, labor-saving, fluid resistance is small, can be operated frequently.

2. simple structure, small shape size, short structure length, small volume, light weight, suitable for large caliber valves.

3. can transport mud and accumulate the least liquid at the pipe mouth.

4. low pressure, good sealing can be achieved. good

5. regulation performance.

6. full open seat channel effective circulation area is larger, fluid resistance is smaller.

7. the opening and closing torque is small, because the butterfly plate on both sides of the shaft is basically equal by the medium action, and the direction of the torque is opposite, so the opening and closing is more labor-saving.

8. sealing materials generally use rubber, plastic, so low pressure sealing performance.

9. easy to install. 10. Flexible and labor-saving operation, can choose manual, electric, pneumatic, hydraulic mode.

Applicationg

|

|

|

1 |

The design can be suitable for BS/ANSI/DIN/UNI/JIS standand. |

|

2 |

For water,neutral liquids,oil and Air etc. |

|

3 |

Coating epoxy painting,150 um. |

| Main Parts and Materials | ||

|

Number |

Part Name |

Material |

| 1 |

Disc |

Ductile iron with nickel plated,Bronze ,Stainless steel SS304 and SS316 |

|

2 |

Body |

Cast iron or Ductile iron |

| 3 |

Stem |

Stainless steel |

| 4 |

seat |

NBR,EPDM,VITON,PTFE |

| 5 |

O ring |

NBR |

|

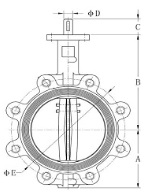

Main Dimensions |

||||||||

|

Size |

A |

B |

C |

D |

E |

|||

| mm |

125/150LB |

PN10 |

PN16 |

10K |

||||

| 25 |

61 |

110 |

32 | 12.7 | 79.4 | 85 | 85 | 90 |

| 32 | 61 | 110 | 32 | 12.7 | 88.9 | 100 | 100 | 100 |

| 40 | 70 | 145 | 32 | 12.7 | 98.4 | 110 | 110 | 105 |

| 50 | 76 | 162 | 32 | 12.7 | 120.7 | 125 | 125 | 120 |

| 65 | 89 | 174 | 32 | 12.7 | 139.7 | 145 | 145 | 140 |

| 80 | 95 | 181 | 32 | 12.7 | 152.4 | 160 | 160 | 150 |

| 100 | 114 | 200 | 32 | 15.9 | 190.5 | 180 | 180 | 175 |

| 125 | 127 | 213 | 32 | 19.1 | 215.9 | 210 | 210 | 210 |

| 150 | 139 | 225 | 32 | 19.1 | 241.3 | 240 | 240 | 240 |

| 200 | 177 | 260 | 38 | 22.2 | 298.5 | 295 | 295 | 290 |

| 250 | 203 | 292 | 38 | 28.6 | 362 | 350 | 355 | 355 |

| 300 | 242 | 337 | 38 | 31.8 | 431.8 | 400 | 410 | 400 |

| 350 | 277 | 368 | 45 | 31.8 | 476.3 | 460 | 470 | 445 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

X

X