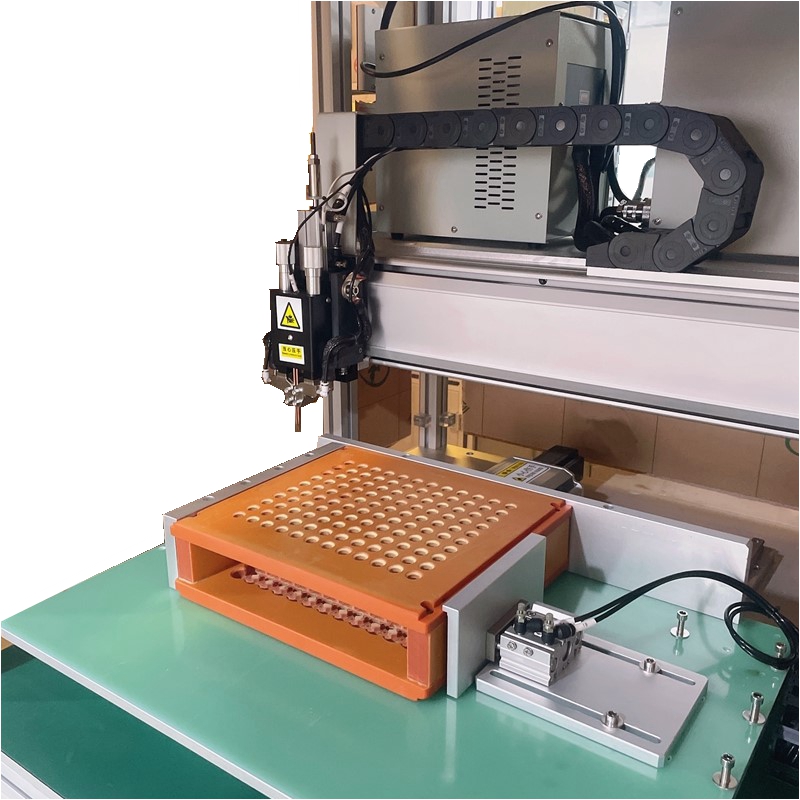

ACEY-S200C with welding head rotation function, is suitable for battery pack spot welding and assembly in the factory for 14500 / 18650 / 21700 / 26650 / 32700 multi-parallel multi-series combination.

Automatic Single Side Rotary 18650 Lithium Battery Pack Spot Welding Machine

Description

The Automatic Battery Pack Spot Welder is a general platform of automatic processing technology based on CNC, suitable battery pack spot welding and assembly in the factory. Compared with manual spot welding machine, the efficiency and accuracy of welding have been greatly improved.

Features

1. Induce load voltage, control voltage by feedback, and realize high quality welding.

2. Preheat, Main Heat's power mode, preheating before welding, to ensure stable welding quality.

3. Keep the continuity of energy density, shorten the welding time, and reduce the deformation and color of base metal. (Welding time controlled in microseconds, continuous output mode)

4. Easy to change from low current to high current, suitable for precision welding.

5. The upper and lower limits of current can be set to simply judge whether the welding quality is good or not, which is suitable for welding automation platform.

6. Can be matched with the production line of lithium battery group.

Specification

|

Model No. |

ACEY-S200C |

|

Y-axis travel |

500mm (customizable) |

|

X-axis travel |

400mm (customizable) |

|

Max spot welding speed |

0.35s/point (1 hour:about 2800 units18650 cells) |

|

Motor drive speed |

600mm/S |

|

Rotation Angle |

180° |

|

Max load electric cores |

X direction: 26; Y direction: 26 |

|

Capable file group storage |

100 groups |

|

Operating system |

embedded system human-machine interface |

|

Transmission mode |

Taiwan precision screw with guide rail |

|

Driving mode |

stepper servo motor |

|

Repeat positioning accuracy |

±0.02mm |

|

Dimensions |

L: 900mm, W: 900mm, H: 1650mm |

|

Power |

2000W |

|

Machine weight |

150KG |

|

Max bearing weight of Y-axis |

30KG |

|

Input power supply |

single-phase AC 220V/50Hz |

|

Air Source |

0.4-0.6 Mpa |

Product details

X

X