Original Japaness Asahi technology and parts, long working life and stable running to produce perfect die cut product for the end user.

Automatic Flatbed Die-cutter AP-165E II

| Model | AP-165EII |

| Paper size | 1200X1650mm |

| Minimum paper size | 500X600mm |

| Maximum die cutting size | 1180X1630mm |

| Standard bite | 15(±5)mm |

| Die cutting pressure | 350tons |

| Corrugated paper thickness | 1-9mm |

| Maximum die cutting speed | 5000i.p.h |

| Total power consumption | 36KW(Key motor 22KW) |

| Total Weight | 38tons |

Features in Performance

Feeding Section

The newest servo drive and vacuum suction belt feeding system (lead edge feeding type) guarantees the smooth feeding of large size cardboard and improves the operation and production ability. Highly precise feeding without damaging the cardboard strength.

Suitable for all kinds of paper, and data setting can be adjusted on the touch screen.

Big size front and side baffles make cardboard at right position, providing high die-cutting precision.

Paper leveling device is specially designed for bent cardboard, stopping cardboard cover the front baffle.

Press Section

Steady die-cutting performance guarantees the high precision. Strong and reliable high speed driven guarantees the smooth running of gripper bar.

Die-cutting frame locking structure, the die cutting steel plate is used air reducer to reduce the weight, easy control. With transducer to prevent the plate in wrong position which resulting defects brought by deflected creasing line.

Die-cutting positioning device can realize quick locating and higher accuracy of die-cutting.

The hardness die-cutting steel plate can be installed easily and quickly.

Transmission and Lubrication System

Quick Plate-change (Optional)

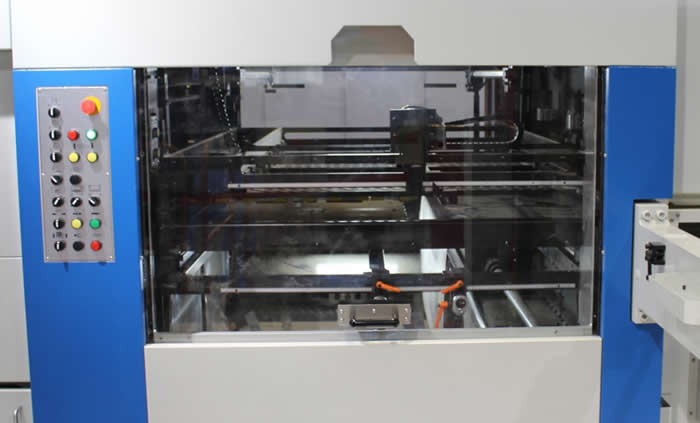

Stripping Section

The quick-setting way of die is adopted; operator can finish the setting from exterior without entering the machine.

Male and female die can be inserted into the machine from operation side to shorten the setup time and for higher safety.

Upper and lower frames make the dies succeed in performance. Male and female dies can move up and down,making stripping more completely.

A plastic film is set between die cutting section and lower frame for stopping paper swerve. It can be adjusted by moving hand crank according to the size on the dies operation direction..

Knock-off Setting

Grip Edge Waste Removal Device

Delively Section

Front and back barriers with side aligning device make receiving tidy.

Side baffle and back barrier coordinate and can be adjusted by motor based on the size on productiion direction.

Delivery platfrom is driven by motor, easy for setting.

Temporary receriving device controlled by servo-actuator makes delivery more simple and easy.

Semi-Auto-Pre-Feeder (Optional)

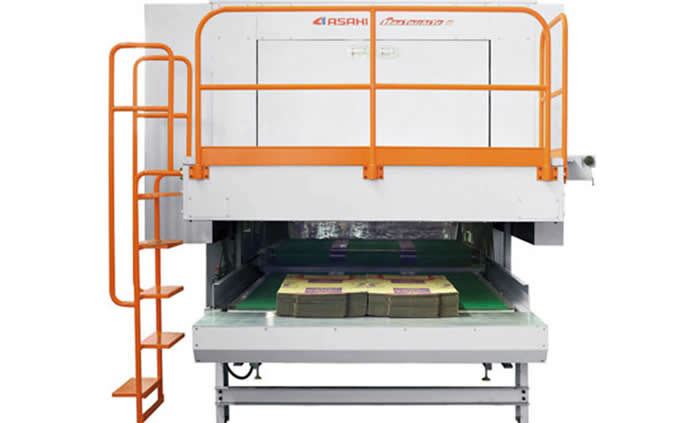

Turn Table and Breaker (Optional)

Addaptable unit used to automatically separate the blanks in bundle format after the die-cutting process. 4 piles can be separated in one process using our high pressure hydraulic system.

X

X