We are the promoter who promote the value of die casting machine greater.

Product Item:

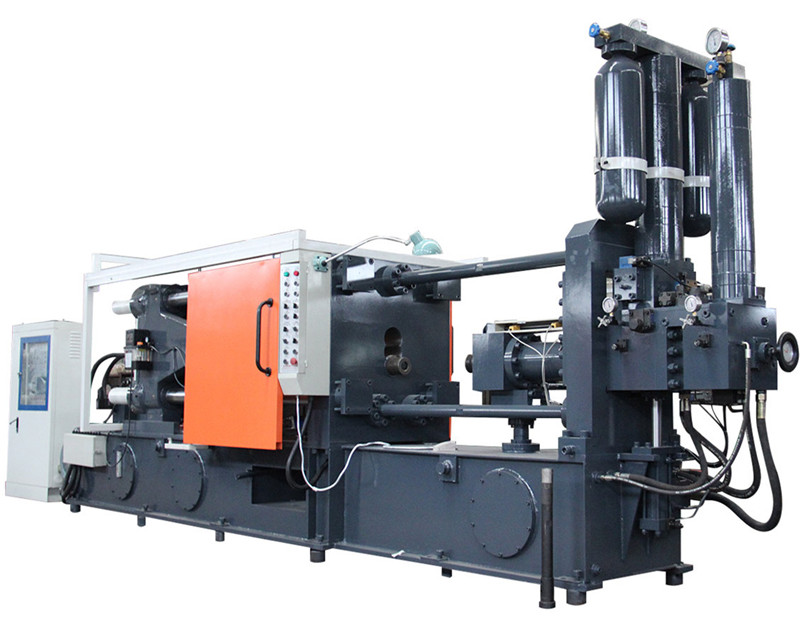

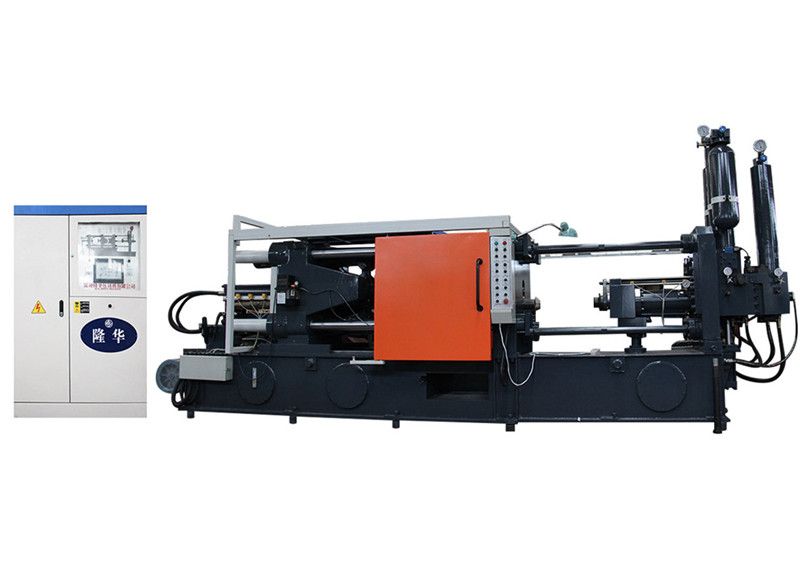

Automatic energy-saving die casting machines to make knife housings(LH-300T)

Cold chamber die casting machine is equipped with double buffer device of unlocking mold, which greatly improves the machine life and stability. Circulating central lubrication system, which can be continuously filled with lubricating oil, and can be recycled after filtering, equipped with oil shortage alarm device, make the machine in a good lubrication state for a long time, reduce the waste of lubricating oil and improve the life of the machine.

LH SERIES OF STANDARD PARAMETER TABLE (LH-300 T)

|

ITEMS |

UNIT |

SPECIFICATION |

|

HYDRAULIC WORKING PRESSURE |

MPA |

14 |

|

CLAMPING FORCE |

KN |

3000 |

|

SPACE BETWEEN TIE BARS |

MM |

560*560 |

|

TIE BAR DIAMETER |

MM |

¢110 |

|

DIE OPENING STROKE |

MM |

420 |

|

INJECTION FORCE(INTENSIFY) |

KN |

240 |

|

PLUNGER LAUNCH DISTANCE |

MM |

140 |

|

INJECTION POSITION |

MM |

0 -- 160 |

|

PLUNGER DIAMETER |

MM |

¢50----¢70 |

|

INJECTION STROKE |

MM |

420 |

|

CASTING PRESSURE (INTENSIFY) |

MPA |

143/99/73 |

|

CASTING FIANGE PROTRUSION |

MM |

12 |

|

CASTING FIANGE DIAMETER |

MM |

110 |

|

MAX CASTING AREA UNDER 40MPA |

CM2 |

700 |

|

LNJECTION WEIGHT(AL) |

KG |

3.5 |

|

DIE HEIGHT(MIN--MAX) |

MM |

250~650 |

|

EJECTOR FORCE |

KN |

150 |

|

EJECTOR STROKE |

MM |

120 |

|

MOTOR CAPACITY |

KW |

15 |

|

MACHINE DIMENSIONS (L*W*H) |

M |

6.4*1.7*2.8 |

|

REFERENTIAL MACHINE WEIGHT FOR UPLIFTING |

T |

12.5 |

|

OIL TANK CAPACITY |

L |

750 |

PS:WE RESERVE THE RIGHT TO MAKE ANY TECHNICAL IMPROVEMENT WITHOUT FURTHER NOTICE

Requirements for maintenance of die casting machine

1. Clean all sundries within the operating range of the machine before starting each time.

2. Carefully check whether the safety protection device and travel switch are normal, and whether the emergency stop button is normal.

3. When cleaning the pressure chamber and punch, do not touch or extend your hand into the pressure chamber.

4. Do not put fire or heat source near accumulator and hydraulic pipeline system.

5. Do not remove, modify and adjust safety protection devices and components at will, and get the support of the machine manufacturer when necessary.

6. Each time the oil pump is started, the "stop" position of each operation switch must be confirmed.

7. Do not clean the electrical box with compressed air.

X

X