1/4 Inch Portable Mini Air Operated Double Diaphragm Pump does not need to divert water, both can pump flowing liquid, and can transport some not easy to flow medium.

AOK06/10-AL Product description :

This is a portable pneumatic diaphragm pump that can transport all kinds of corrosive liquids, liquids containing particles, high-viscosity liquids, volatile liquids, flammable and explosive liquids.

|

|

AOK06/10-AL Performance Parameter:

|

Model |

AOK06/10 |

|

|

Inlet/ Outlet size |

mm |

6/10 |

|

inch |

1/4 or 3/8 |

|

|

Flow Rate

|

m3/h |

1.62 |

|

L/min |

27 |

|

|

Head (m) |

70 |

|

|

Suction Stroke (m) |

6.4 |

|

|

Max. Particle Diameter (mm) |

1.6 |

|

|

Max.Air Pressure (kg/cm²) |

7 |

|

|

Max.Air Consumption (m³/min) |

0.14 |

|

|

Diaphragm |

Teflon, Hytrel, Viton, Santoprene, Buna-N, etc. |

|

|

Check Valve |

PP, PVDF, POM |

|

|

Center block |

PP |

|

More Options ( Parameters Table):

|

Model |

Flow (m³/h) |

Head (m) |

Suction Stroke(m) |

Max.Particle Dia. (mm) |

Max. Air Pressure (kg/cm²) |

Max.Air Consumption (m³/min) |

|

AOK06/10 |

0-1.62 |

0-70 |

6.4 |

1.6 |

7 |

0.14 |

|

AOK-15 |

0-3.42 |

0-84 |

7.6 |

2.5 |

8.4 |

0.56 |

|

AOK-25 |

0-9.42 |

0-84 |

8 |

4 |

8.4 |

1.12 |

|

AOK-40 |

0-21.48 |

0-84 |

8 |

5 |

8.4 |

2.24 |

|

AOK-50 |

0-35.22 |

0-84 |

8 |

6 |

8.4 |

2.8 |

|

AOK-80 |

0-63.6 |

0-84 |

8 |

9.4 |

8.4 |

9.8 |

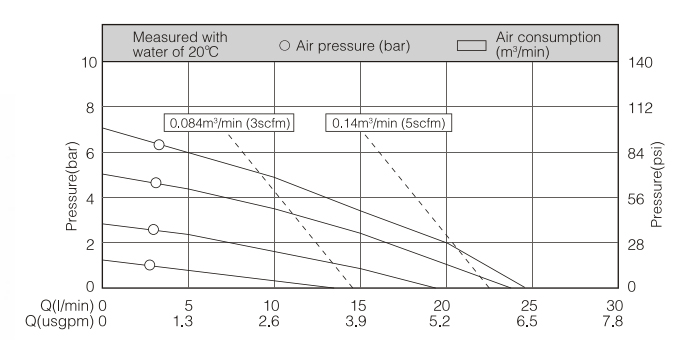

Performance curve:

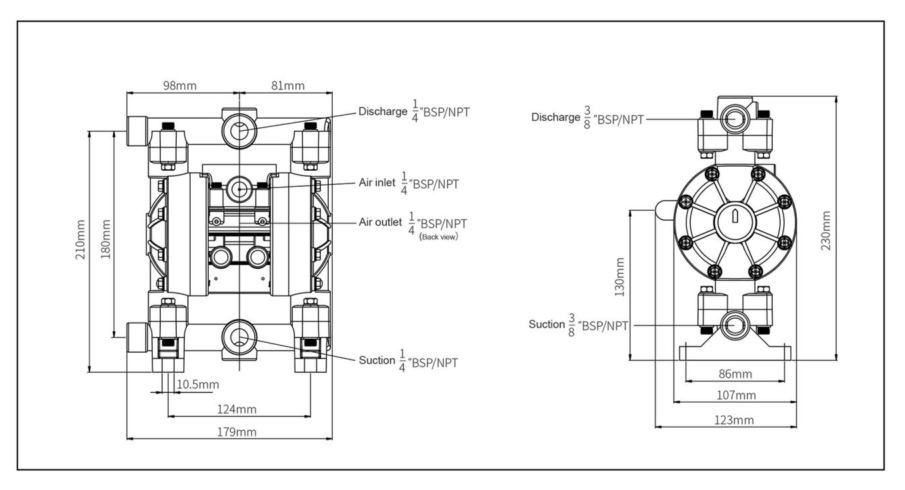

Installation size:

Applications:

Chemical industry

Petrochemical industry

Mining industry

Ceramic industry

Environmental protection industry

Paper industry

Electronics industry

Furniture industry

Construction industry

Automotive industry

Metallurgy, casting and dyeing industry

Working Principle:

When air pressure is applied to the pump, the main air valve moves up and down. When the main air valve is in the down position, air pressure is diverted to the right diaphragm. At the same time, exhaust air from the left diaphragm passes through the shuttle and shuttle plate, and exits the rear of the pump. When the main air valve is in the up position, air pressure is diverted to the left diaphragm while the right diaphragm is exhausted. This process constantly alternates between the up and down position to create a continuous cycle.

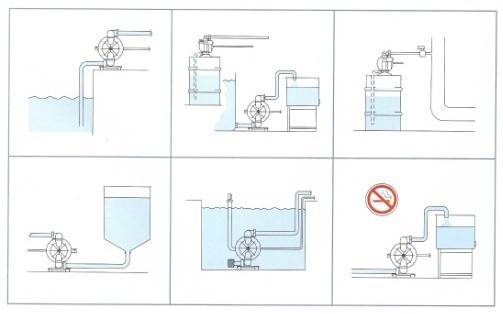

Installation diagram:

Material Table

(More pumping medium pls contact us to confirm the suitable material)

|

Item |

Pump Body |

Diaphragm |

||||||

|

Medium |

Polypropylene |

Aluminum |

PVDF |

Stainless Steel |

Buna-N |

Geolast |

Viton |

Teflon |

|

Chloronaphthalene |

× |

× |

|

B |

D |

D |

C |

A |

|

Acetic Acid _ 50% |

|

× |

|

A |

C |

C |

C |

A |

|

Ammonium Bicarbonate |

|

B |

|

|

A |

A |

A |

A |

|

Ammonium Chloride |

A |

× |

A |

B |

A |

A |

A |

A |

|

Amyl Borate |

|

|

|

|

A |

B |

A |

A |

|

Aniline Dyes |

|

B |

|

B |

C |

C |

B |

A |

|

Barbeque Sauce |

|

|

|

A |

A |

A |

D |

A |

|

Beer |

A |

A |

A |

A |

C |

A |

A |

A |

|

Calcium Chloride |

A |

A |

A |

A |

A |

A |

A |

A |

|

Carbonic Acid (liquid) |

A |

|

|

B |

B |

A |

A |

A |

|

Diesel Oil |

B |

A |

A |

A |

A |

C |

A |

A |

|

Honey |

A |

A |

|

A |

D |

A |

D |

A |

|

Glue |

A |

A |

|

B |

A |

A |

A |

A |

|

Formic Acid |

A |

× |

A |

C |

C |

B |

C |

A |

|

Lactic Acid |

A |

A |

A |

A |

B |

B |

A |

A |

|

Hydrochloric Acid 30% |

B |

× |

A |

× |

C |

C |

B |

A |

|

Sulfuric Acid 50% |

A |

× |

A |

× |

C |

B |

A |

A |

|

A : Excellent - Recommended ;B : Good - minor to moderate effect; C : Poor - Moderate to severe effect; D : Unsatisfactory - not recommended |

||||||||

X

X