Insulated Polyisocyanurate (PIR) sandwich panels in 75mm thickness,is a favorable choice for cold room projects. MOQ:500 M²/ Color & Size.

Product advantages

☆ Yumisteel offers two ways of joint:

Concealed nails joint, no surface decoration is required;

Overlap joint,it’s suitable for cold storage projects.

☆ B1 and B2 level PIR fire resistant panels for your choices.The max available temperature is 180℃.Under the action of flame, it has carbon deposits, no drips, no curls, and no melting.

☆ The panel has super carrying capacity, and it’s not easy to deform.This wall has superior mechanical properties and reduces dependence on auxiliary steel structures.

☆ The construction cycle can be shortened by more than 40%.Due to panels are less affected by bad weather, it is more convenient to install and has a shorter construction period than traditional construction methods.

PU sandwich panels are widely used in purification and clean workshops, modular houses, freezers, cold room projects, indoor partitions, automotive paint rooms, etc. Further detailed description, this kind of panel can be used in electronics, medical, food, vegetable preservation, large-scale cold storage and civil buildings and other internal and external walls.

Here we listed some project pictures for your reference:

Machinery Technology Co., Ltd.

Auto car parts company

Software center

University Institute

Product specifications

|

Product name |

75mm PU foam panel |

Remark |

|

Effective width |

930, 1000, 1120 mm |

|

|

Panel thickness |

75 mm |

Other thickness for roof: |

|

30, 35, 40, 50, 60, 100, 150, 200, 250 mm |

||

|

Surface sheets |

PPGI/ PPGL/ Aluminum sheets/ Al-Mg-Mn alloy metal sheets/ Stainless steel |

|

|

Steel thickness |

0.40 - 0.70 mm |

|

|

Aluminum sheets/ Al-Mg-Mn alloy metal sheets |

0.70 - 1.20 mm |

|

|

Stainless steel |

0.40 - 0.60 mm |

|

|

Regular panel color |

White grey, Sea blue, Sliver grey, Dk grey, Iron grey |

Color could be customized too. |

|

Coating type choice |

PE/ PVDF/ HDP/ SMP, etc. |

|

|

Available length |

20FT container: ≤ 5.95m |

|

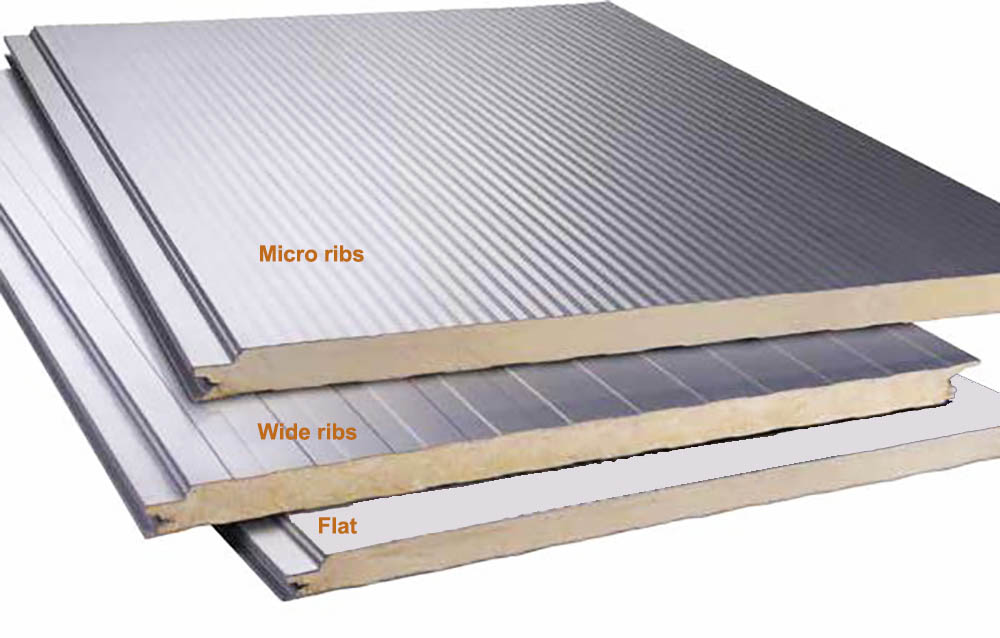

Product ribs

We have three different kinds of wall panel surface treatment,there are micro ribs,wide ribs,and flat.If you have special requirement,you can choose as per your wish.

Packing & Delivery

☆ Packing:

·13 ~ 16 panels per package;

·20FT container max loading quantities:

|

Effective width |

930 mm |

1000 mm |

1120 mm |

|

Loading quantities /m² |

332.01 |

357 |

399.84 |

|

Packages |

4 |

4 |

4 |

|

Effective width |

930 mm |

1000 mm |

1120 mm |

|

Loading quantities /m² |

755.718 |

812.6 |

910.112 |

|

Packages |

5 |

5 |

5 |

PVC on both sides to protect the roof panel surfaces;

Packed with kraft paper to protect the panel ends;

Put EPS foam on the each space to keep the panels from squeezing each other.

If you have special requirement,please feel free to discuss with us.This is to make us improved,and protect your goods well.

☆ Delivery:

Delivery time for regular colors,coating types and thickness: 7-10 days ;

Delivery time for special colors,coating types and thickness: 15-25 days ;

Delivery term: FOB/CIF/CFR/DDP is available;

We can find good forwarder for customer or accept appointed forwarder from customers.

X

X