60 Ton water cooled screw chiller for extruder process OMC-60WSH. Shell and tube condenser, Plastic extrusion water screw chiller cooling capacity from 30Ton to 600Ton optional.

60 Ton water cooled screw chiller for extruder process

In the process of industrial production in which the extruder participates, the cooling water tank of the extruder absorbs a large amount of heat from the extruded parts, and the temperature rises quickly. If refrigeration and cooling equipment is not installed, the water tank of the extruder will not meet the cooling requirements, which will seriously affect the quality of the extruded parts.

To reduce the

temperature of the cooling water tank of the extruder, the problem of

excessively high temperature of the cooling water tank of the extruder can be

solved only by installing an extruder chiller.

The chiller for cooling the extruder is called an extrusion chiller. Also called plastic extrusion cooling system. Since the

extruder is mainly used for various extruded plastic products, such as PE, PP,

PVC, ABS, etc., the high temperature generated during the production process

will cause difficult demolding and slow molding, so a chiller is required to

provide low-temperature cycle freezing Water (5-30°C) is fed to the extruder to

shorten the cooling time and improve product quality.

The extruder

chiller is a kind of cooling water equipment that can provide constant

temperature, constant current and constant pressure. The working principle is

to first inject a certain amount of water into the water tank in the machine,

cool the water through the refrigeration system of the industrial refrigerator,

and then send the low-temperature cooling water to the equipment that needs to

be cooled by the water pump, and the chilled water of the refrigerator will take

away the heat after the temperature It is raised and then returned to the water

tank to achieve cooling. The cooling water temperature can be automatically

adjusted according to requirements, and long-term use can save water.

Therefore, it is a standard energy-saving refrigeration equipment.

When choosing a chiller for the extruder, you should pay attention to the following points: First, we must confirm whether the customer’s extruder has an open sink, if so, when choosing a chiller, you should choose a shell-and-tube type or a plate Replace the evaporator instead of the water tank coil type evaporator. If there is no sink or pool, you should choose a water tank coil type evaporator.

The second is the selection of the extruder. When selecting a chiller, we must calculate the chiller power based on the temperature of the water in the extruder tank, the amount of water used per hour, and the temperature of the return water. As the heat generated by the extruder in a short period of time is relatively large, in order to ensure the cooling effect, a slightly larger value is generally selected, which can avoid the full-load operation of the chiller and ensure the stability of the cooling.

The last is the selection of the cooling type of the chiller. Many customer factories are equipped with cooling water towers. In this case, it is better to choose a water-cooled chiller. The water-cooled chiller uses the water tower to dissipate heat and has higher cooling stability; if there is no cooling water tower and the cooling power of the chiller is low, it is recommended Use air-cooled chillers; users with higher cooling power (such as 40hp 50hp chillers) should use water-cooled chillers with cooling towers for cooling.

Plastic extrusion cooling system Product Information

●:Temperature control 5℃ to 35℃

●:Shell and tube evaporator and condenser

●:Bizer or Hanbell semi-hermetic screw compressor

●:Optional refrigerant R134a,R407c and R404a

●:Schneider Electrical Components

●:PLC/ Touch Screen Control Panel

●:No water tank, connect an external water tank

●:Need to connect a cooling tower

●:Safety protection devices of whole screw chiller

●:All models and cooling capacity available

Extrusion chiller Product display

The chiller for extrusion production lince includes four main components of the vapor compression refrigeration

cycle (compressor, evaporator, condenser, circulating pump), these machines can

realize different refrigerants. Compression refrigerators use refrigerants as

refrigerants to achieve a strong affinity for refrigeration effects.

1. The extruder

chiller adopts fully-sealed, low-noise, low-vibration, high-efficiency and

power-saving imported brand-name compressors, all electrical control adopts

imported original parts, and the heat exchanger adopts a shell and tube condenser,

which has high heat exchange efficiency and is easy to clean and maintain .

2. Energy-saving

and economical: The digital electronic thermostat can accurately control the

temperature of cold water between +3℃ and 50℃, thereby controlling the normal

operation of the unit, saving energy, and all the unit assembly, internal

wiring, refrigerant filling and debugging are all in The factory is over.

3. Safe

operation: The machine body is equipped with compressor delay starter,

overcurrent relay, high and low pressure device, fuse plug, electronic time

safety valve, to ensure the normal operation of the unit.

4. Condenser:

High-efficiency threaded steel pipes are used. Both ends of the cover can be

interchanged to change the direction of the water pipe. The water pipe process

is multiple times. Each condenser is matched with the compressor capacity. The

straight-through water pipe is easy to clean and maintain.

60 Ton Water Cooled Screw Chiller Application

60Ton water cooled screw chiller use for extrusion cooling system. The extruder chiller is used for hard pipes, hoses, profiles, glue sticks, automotive glass sealing strips, cables, corrugated pipes, packaging bags, door and window sealing strips, etc. In addition to the plastic extrusion industry,the water cooled screw chiller also can used in many industry, such as medical industry, food cooling system, metal finishing process......

50 Ton Screw chiller Product Specification

|

Item Model |

OMC-60WSH |

||

|

Cooling Capacity |

kcal/h |

173376 |

|

|

KW |

201.6 |

||

|

Ton |

57.3 |

||

|

Btu/h |

688055 |

||

|

Input Power |

KW |

42.3 |

|

|

Max.running Current |

A |

112 |

|

|

Power supply |

|

3PH-380V/415V 50HZ(220V/440V 60HZ)) |

|

|

Refrigerant |

Type |

|

R22 |

|

Charge quantity |

kg |

42 |

|

|

Control Mode |

|

Expansion Valve |

|

|

Compressor |

Type |

|

Semi-Hermetic Screw |

|

Power |

KW |

42.3 |

|

|

Start-up Mode |

|

Y-△ |

|

|

Capacity Control |

% |

0-25-50-75-100 (0-33-66-100) |

|

|

Evaporator |

Type |

|

Shell and Tube |

|

Chilled water flow |

m3/h |

34.7 |

|

|

Pipe Diameter |

lnch |

3" |

|

|

Condenser |

Type |

|

Shell and Tube |

|

Cooling water flow |

m3/h |

42.0 |

|

|

Pipe Diameter |

lnch |

3" |

|

|

Dimension |

Length |

mm |

2450 |

|

Width |

mm |

985 |

|

|

Height |

mm |

1600 |

|

|

Net Weight |

kg |

1120 |

|

|

Running Weight |

kg |

1270 |

|

|

Safety Protection:Compressor over temperature protection, over load protection, high and low pressure protection, anti-freezing protection, reversed and lacking phase protection, fusible blug, flow switch |

|||

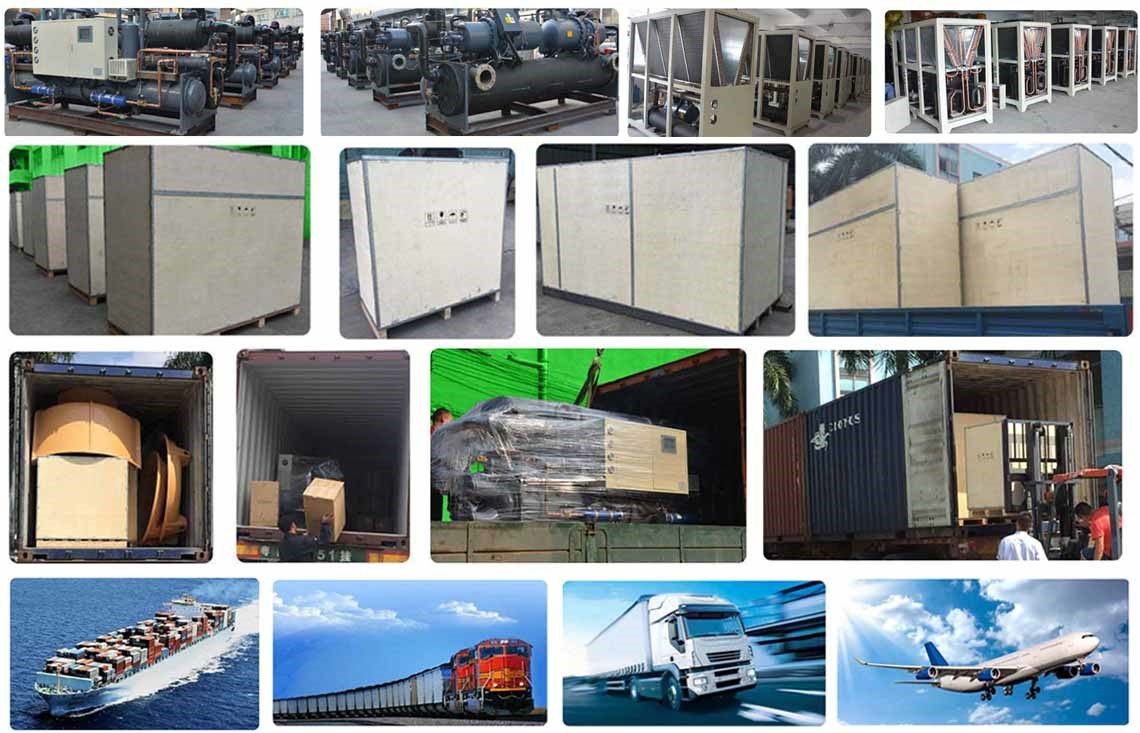

Packing & Shipping

FAQ

Q1: Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2: How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as copeland, danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3: What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4: Whats your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5: Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance.

The control box design make the unit safety and stably.

Q6: How can i Place an order ?

A6: Click Below to fill the table or Call 0086 15112554736

X

X