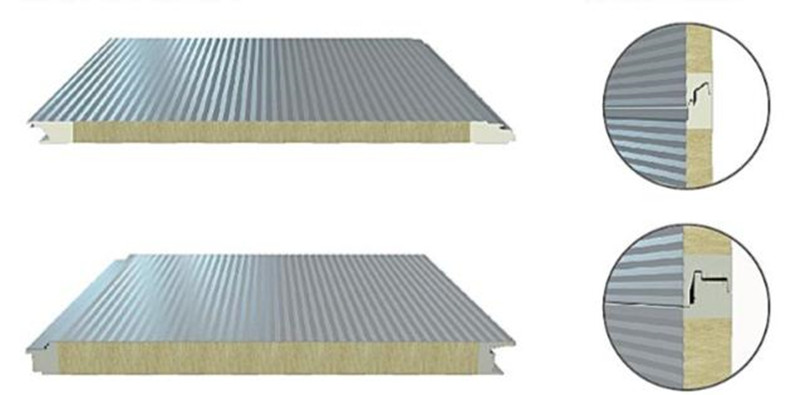

50-150mm Thickness Rockwool+PU Sandwich Panel For Metal Wall Cladding System

Product Introduction

With experience in independent research and development of the metal cladding system in the past over 40 years, Wiskind has launched the Color Pod™, Rockwool+PU Sandwich Wall Panel. Its tongue-and-groove is filled by high-density rigid PU foam, goes through high-pressure foaming solidification and 90°automatic dense wool arrangement and realizes forming through super long precision double-track control. Due to its thermal insulated, fireproof and durable performance, convenient installation method and elegant appearance, it has rapidly become a main cladding system material for industrial buildings.

Product Parameters

|

Brand of steel plates: |

Bao Steel, Yieh Phui Steel, Ma Steel, BHP Steel. |

|

Painting of steel plates: |

PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

|

Galvanized layer of steel plates: |

Exterior plate:55% Aluzinc above 100g/m³or Zinc coating above 150g/m³; Inner plate:55% Aluzinc above 70g/m³or Zinc coating above 100g/m³. |

|

Thickness of steel plates: |

0.4mm-0.8mm. |

|

Thickness of core: |

50mm/75mm/80mm/100mm |

|

Density of core: |

Rockwool:≥120kg/m³; Glasswool: 64kg/m³; PU: 40-50kg/m³ |

|

Effective width: |

1000mm |

|

Panel Length: |

According to customers’ request |

Performance Description

1. The flame resistance level reaches the level A, which has improved the overall fireproof performance of steel buildings.

2. The two edges of the tongue-and-groove is filled with polyurethane foams, which effectively stops heat conduction and rain leakage, prevents reduction of strength and thermal insulation performance caused by moisture absorption and makes fireproof and thermal insulation performance more durable.

3. The high volumetric weight core material guarantees better thermal insulation performance (the volumetric weight of rock wool core material ≥ 120kg/m3, the volumetric weight of glass wool ≥ 64kg/m3).

4. The two edges of the tongue-and-groove is filled with rigid polyurethane foams to improve the overall strength and prevent deformation of the tongue-and-groove.

5. The fireproof wool rotates 90°so that the wool fiber is perpendicular to the panel and the strength of pressure and tension resistance increases by 50%.

X

X