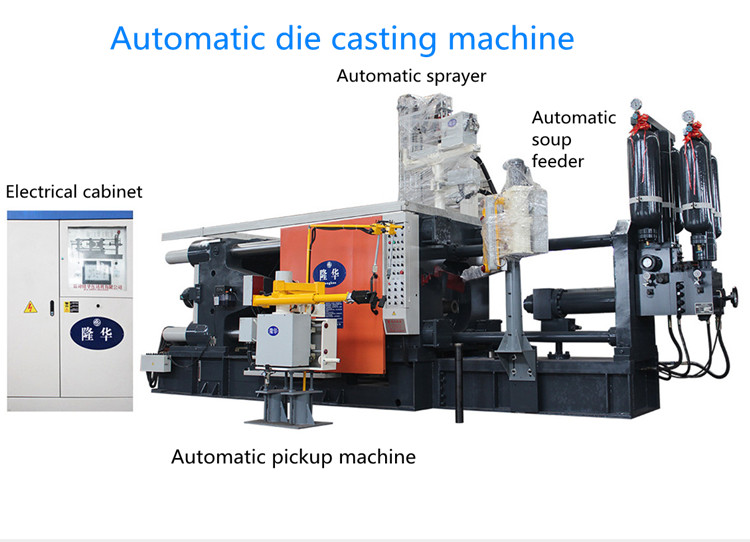

Longhua die casting machine is characterized by energy saving and high efficiency. Combined with automatic equipment, it can realize the full range operation of machine instead of human.

Fully Automatic Aluminum Alloy Horizontal Die Casting Machine

Parameters of cold chamber die casting machine(140T)

|

Items |

Unit |

Specification |

|

Hydraulic Working Pressure |

MPa |

7 |

|

Clamping Force |

KN |

1400 |

|

Space Between Tie Bars |

mm |

420*420 |

|

Tie Bar Diameter |

mm |

¢80 |

|

Die Opening Stroke |

mm |

350 |

|

Injecction Force(intensify) |

KN |

180 |

|

Plunger launch distance |

mm |

120 |

|

Injection position |

mm |

0 -- 140 |

|

Plunger Diameter |

mm |

¢40----¢60 |

|

Injection Stroke |

mm |

320 |

|

Casting pressure (intensify) |

MPa |

143/92/64 |

|

Casting Fiange Protrusion |

mm |

10 |

|

Casting Fiange Diameter |

mm |

110 |

|

(40Mpa) Max Casting Area Under 40Mpa |

CM2 |

375 |

|

lnjection Weight(Al) |

Kg |

1.6 |

|

Die Height(Min--Max) |

mm |

200~500 |

|

Ejector Force |

KN |

100 |

|

Ejector Steoke |

mm |

80 |

|

Motor Capacity |

Kw |

11 |

|

Machine Dimensions (L*W*H) |

m |

4.5*1.2*1.5 |

|

Referential Machine Weight For Uplifting |

T |

4.7 |

|

Oil Tank Capacity |

L |

300 |

1. Easy to handle

- Completely automatic process cycle and analysis function

- Permanent process monitoring via sensors

- Extensive security installations

2.Excellent performance

- High efficiency and reduced scrap

- High quality casting of complex and large parts

- Extremely stable value of the machine

- Multi-shift operation possible

3.Flexible

- Small or large casting clusters

- Non-ferrous metals including zinc, aluminium, bronze and brass alloys

- Moulding chamber easily adaptable for shell-, sand- and block moulds.

1. Double proportional control (electric regulation of pressure and flow, with a multi-level pressure and Speed control as well as low pressure die close protection functions).

2. Dual circuit design (air injection and pressure building are separately designed without mutual interference and fault occurrence).

Packaging and delivery of die casting machines:

We have our own factory, containers can be directly from the factory to extract die-casting machine and related machine parts. Our packing is standard packing. The wooden cases we use are for export use only.

Die casting machine products:

Engine cylinder block, cylinder head, crankcase, hinged door covers, oil pan, gearbox housing, gearbox end cap, dashboard, etc.

Electric escalator handrail/steps,industrial/road/railway/air/agricultural machinery, spotlight shells, building material parts, furniture, aluminum arts, copper arts, magnesium alloy products, non-ferrous metal processed products and other die casting products.

Auto die casting machine composition

X

X