|

Technical |

Specifications : |

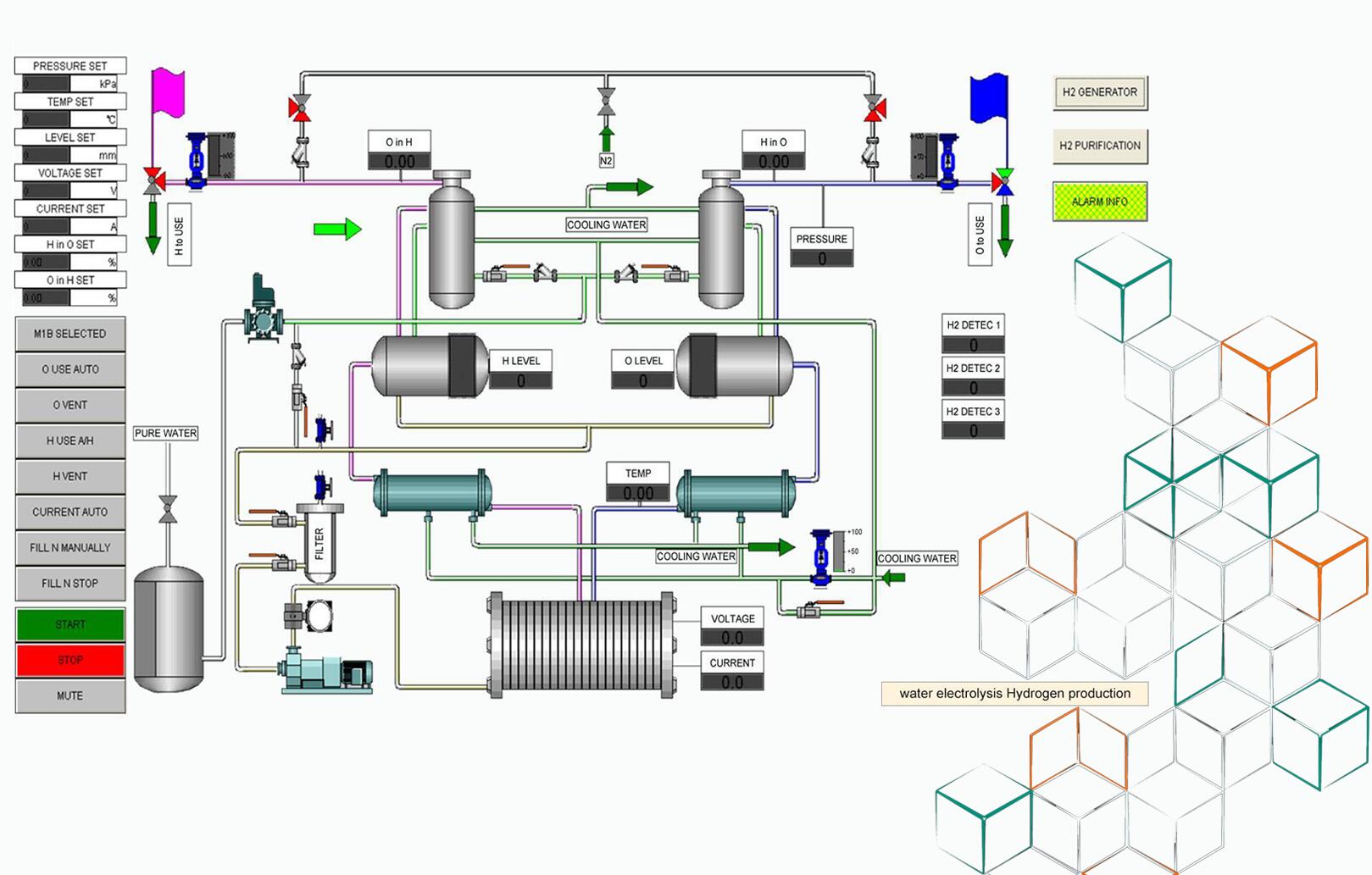

According to the running state and environment of hydrogen production machine , we will help you optimize and upgrade the system, design plans suitable for the operation of the machine, improve the monitoring and detection for DCS and PLC, enhance the running safety and using cycle of hydrogen production equipment, so that reduce system failure caused by peripheral equipment (hydrogen compressor, dryer, PLC controller, etc.) and equipment failure or accident caused by personnel operation mistakes.

In view of the system shutdown caused by the fault of individual components for most users (such as system pressure imbalance and inaccurate measurement of the analyzer caused by the fault of pressure transmitter and ),

we have stable detection methods and equipment maintenance plans for hydrogen production machine.

Professional engineers understand the operation status of your hydrogen production system,

and the performance indicators of core components, and propose solutions to ensure the safe operation of your hydrogen production equipment.

Technical

Characteristics :

Certification

|

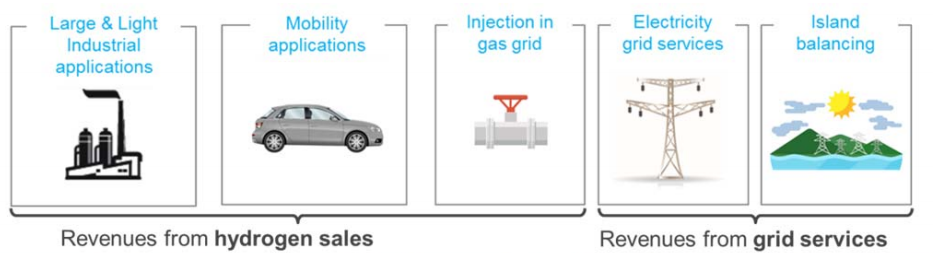

Application Energy Fields |

|

We have accumulated mature technologies in various application scenarios,

such as renewable energy, hydrogen production and storage reuse, fixed/skid-mounted hydrogenation stations,

by-product hydrogen exhaust hydrogen preparation, standby/emergency hydrogen fuel cell hydrogenation,

peak and frequency regulation in thermal power plants and dark green hydrogen microgrid.

We can provide hydrogen production, hydrogen storage and other hydrogen industry chain solutions

X

X