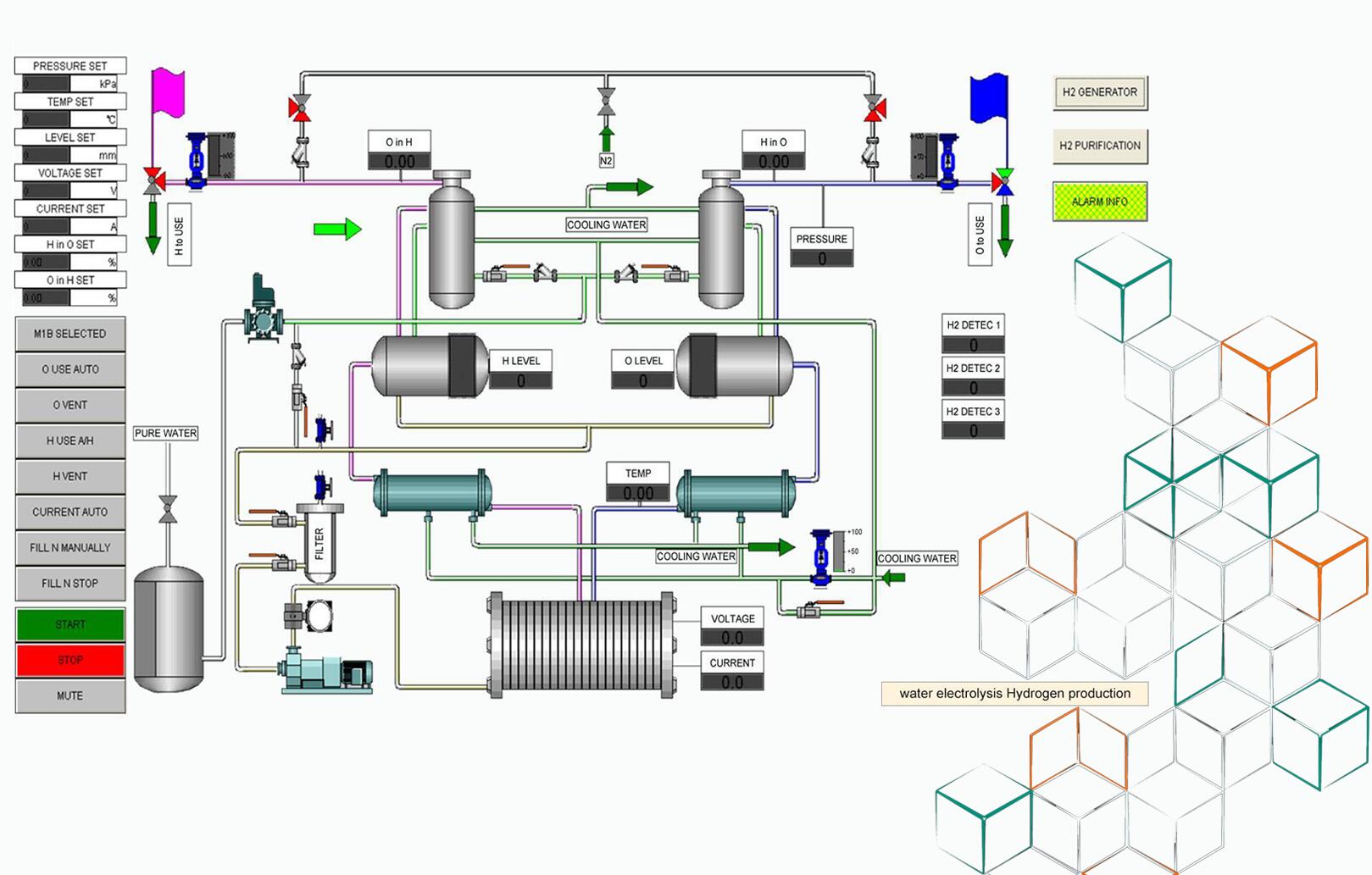

The hydrogen generation equipment developed based on this technology mainly includes:

* Electrolyser: the generator of hydrogen and oxygen

* Auxiliary equipment frame: gas-liquid separation system

* Rectifying transformer + Rectifier: DC power supply unit

* PLC control panel: the automatic control unit

* Feed water & lye making system: include lye tank, feed water tank, lye making pump, this unit is used for making electrolyte solution and feed water storing.

The total system is automatically controlled, the hydrogen, oxygen are supplied under the required pressure.

The cooling water circulation system

It is the supporting equipment of water electrolysis hydrogen production system, hydrogen purification (drying) system or other cooling water system, which helps to improve the stability of electrolysis temperature of water electrolysis equipment and the service life of cooling water pipes and heat exchangers.

Hydrogen bus-bar

The system has reasonable layout, structure connection and high degree of automation, and is widely used in power plants, hydrogen stations and gas companies

Hydrogen purification system

The hydrogen purification unit adopt two (three) dryers to work in turn and feed gas regeneration mode according to the needs of users. The pneumatic valve in the device is controlled by PLC program, which can realize the automatic switching of the working state of the dryer,it has the function of automatic drainage. The hydrogen purity of the product is 99.999%, the oxygen content is less than or equal to 1ppm, and the water content less than or equal to 1ppm (dew point is less than -70 ℃)

Hydrogen recycling device is mainly applied in the condition that large amount of hydrogen is used by the user in the production process,

and the hydrogen is basically not consumed or rarely consumed in the use process.

In order to reduce the operation cost, the used hydrogen is usually recycled.

Hydrogen Recycling Device

The recycling process is mainly based on the pollution of hydrogen in the use process, that is, the types of contaminants and the content of impurities.

Different processes, such as catalytic reaction and molecular sieve adsorption, are adopted to purify hydrogen to meet the requirements of hydrogen purity in the process.

Xiamen Zhongxinda Hydrogen Energy Technology Co., Ltd. has provided customers with several sets of hydrogen recovery system.

The hydrogen processing capacity can reach thousands of cubic meters.

|

How to maintain hydrogen production equipment? |

FAQS |

What is the standard of hydrogen production equipment? |

|

In which sectors is hydrogen used in particular? |

||

|

Is hydrogen only a temporary solution? |

||

X

X