Try to get high purity hydrogen

Hydrogen Purification Equipment

Zhongxinda medium pressure hydrogen purification equipment.

It is equipped with a variety of processes such as hydrogen generated and air separation nitrogen regeneration and three-tower regeneration without consuming raw gas.

Hydrogen with high purity is obtained after catalytic deoxygenation, cooling and condensation, adsorption secondary drying and high efficiency filtration of sintered nickel tube.

The equipment is widely used in electronics, gold, chemical, glass, new energy and other industries.

-

Using palladium and platinum bimetallic deoxidization catalyst, the deoxidization effect can reach the oxygen content ≤1ppm, and the atmospheric pressure deoxidization effect can also reach the oxygen content ≤5ppm.

-

Adopting high quality molecular sieve with large loading coefficient and high adsorption capacity rate,

-

hydrogen moisture content of the product can be ≤-75℃ dew point.

-

Adopting high efficiency sintered nickel tube filter, filtration efficiency can reach 99.9999%. After dust removal, the molecular particle size is ≤0.3μm.

-

The purification working pressure can be adjusted from 0.8MPa to 3.2MPa, and the maximum processing capacity can exceed the design value by 15%.

-

The amount of regenerated gas is 5%-10% of the processing capacity, and the power consumption is zero. If the raw gas regeneration or the three-tower process is adopted, the hydrogen loss is zero.

-

Fully equipped, the device has compact structure and is easy to maintain. PLC+ touch screen (or industrial computer) -- automatic operation.

The cooling water circulation system

The

cooling water circulation system is composed of cooling water tank,

cooling water pump plate heat exchanger, butterfly valve, pipeline, etc

form to a heat exchanger equipment.

It

is the supporting equipment of water electrolysis hydrogen production

system, hydrogen purification (drying) system or other cooling water

system, which helps to improve the stability of electrolysis temperature

of water electrolysis equipment and the service life of cooling water

pipes and heat exchangers.

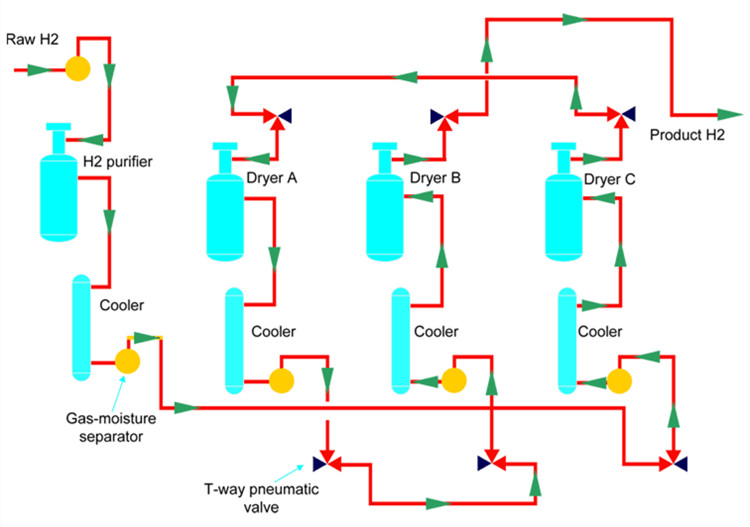

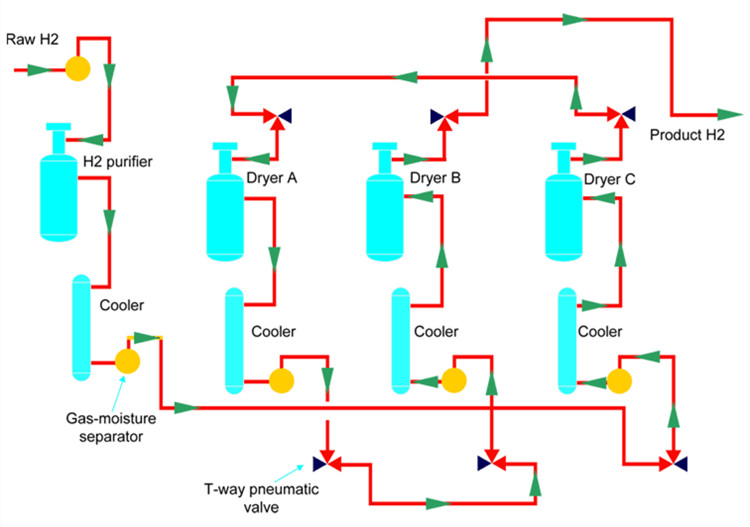

Hydrogen purification system

The hydrogen purification unit adopt two (three) dryers to work in turn and feed gas regeneration mode according to the needs of users. The pneumatic valve in the device is controlled by PLC program, which can realize the automatic switching of the working state of the dryer,it has the function of automatic drainage. The hydrogen purity of the product is 99.999%, the oxygen content is less than or equal to 1ppm, and the water content less than or equal to 1ppm (dew point is less than -70 ℃)

Hydrogen recycling device is mainly applied in the condition that large amount of hydrogen is used by the user in the production process,

and the hydrogen is basically not consumed or rarely consumed in the use process.

In order to reduce the operation cost, the used hydrogen is usually recycled.

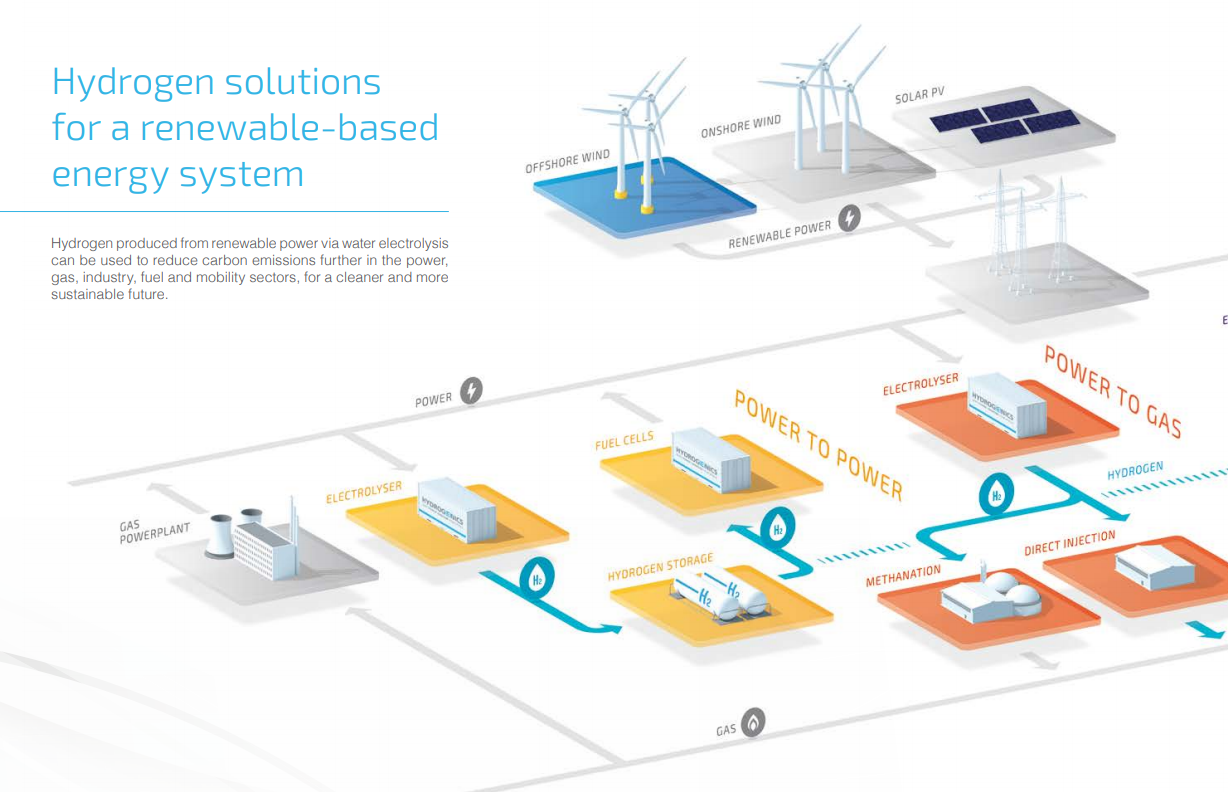

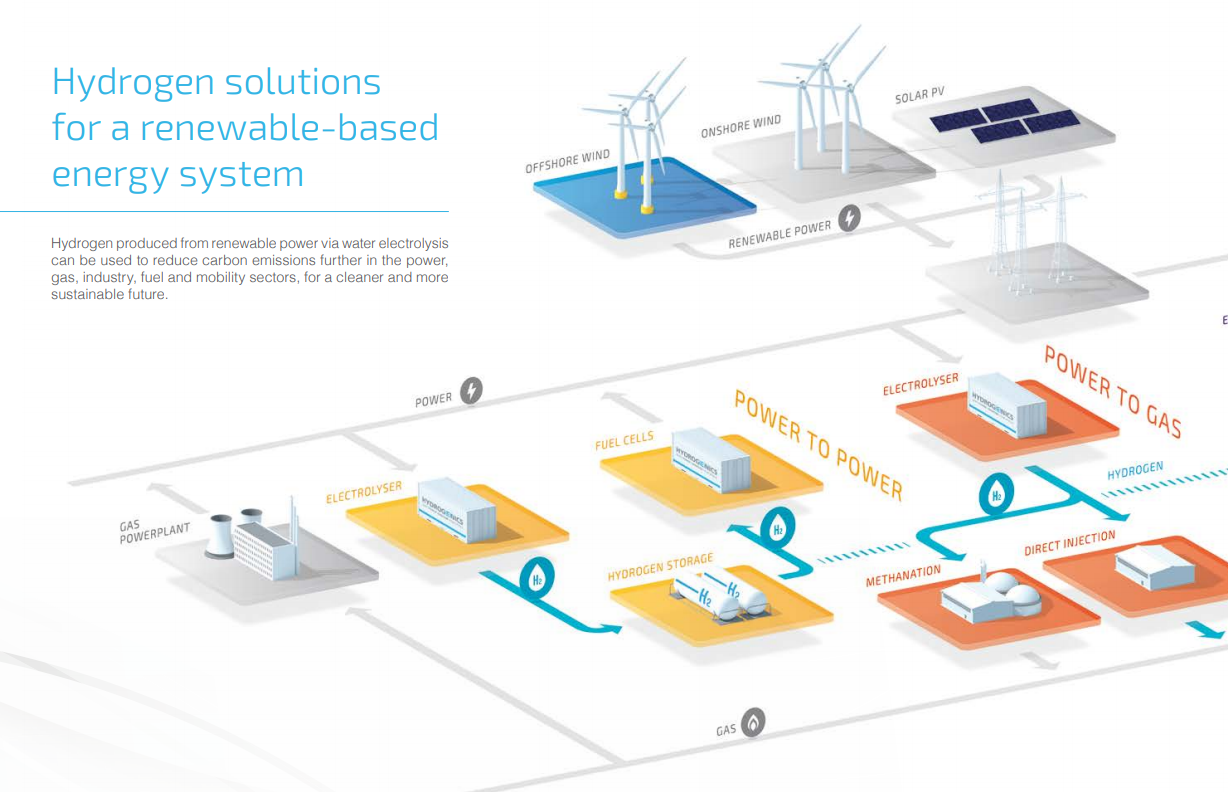

Hydrogen solutions

for a renewable-based

energy system

Quality Control

X

X