|

Technical |

Specifications : |

|

Rectangular plastic frame(ion-exchange membrane) |

||||||

|

No |

12 |

13 |

14 |

15 |

16 |

|

|

Part Number |

ZXD-100/H-0.8 |

ZXD-200/H-0.8 |

ZXD-250/H-0.8 |

ZXD-500/H-0.8 |

ZXD-1000/H-0.8 |

|

|

Hydrogen Production(Nm3/h) |

100 |

200 |

250 |

500 |

1000 |

|

|

Oxygen Production(Nm3/h) |

50 |

100 |

125 |

250 |

500 |

|

|

Working Pressure (MPa) |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

|

|

working temperature |

℃ |

5-80 |

5-80 |

5-80 |

5-80 |

5-80 |

|

Hydrogen Purity(V/V)% |

≥99.9 |

≥99.9 |

≥99.9 |

≥99.9 |

≥99.9 |

|

|

Oxygen purity(V/V)% |

≥99.2 |

≥99.2 |

≥99.2 |

≥99.2 |

≥99.2 |

|

|

Working current(A) |

5300 |

5300 |

5300 |

21200 |

42400 |

|

|

Working voltage(V) |

90 |

180 |

220 |

220 |

220 |

|

|

Weight(t) |

2.9 |

3.4 |

3.6 |

7.5 |

15 |

|

|

Dimensions |

L×W×H |

1695X720X1500 |

2195X720X1500 |

2595X720X1500 |

2595X1600X1600 |

2595X3200X1600 |

Technical

Characteristics :

Overhaul and reconstruction

Professional engineers understand the operation status of your hydrogen production system, and the performance indicators of core components, and propose solutions to ensure the safe operation of your hydrogen production equipment.

In order to ensure the construction period of the maintenance and reconstruction project,

The company has a variety of brands of electrolyzers in stock throughout the year. "Excellent service, professional skills, quick response" is our consistent working attitude.

We provide spare parts for the whole hydrogen production system. Regardless of equipment, components, valves or instruments, we will recommend the most suitable spare parts for your hydrogen production equipment to you according to the operating environment and state of your hydrogen production system. Under the premise of ensuring the safe and normal operation of the equipment, we will develop a cost-effective solution to save the maintenance and operation costs for you to the maximum!

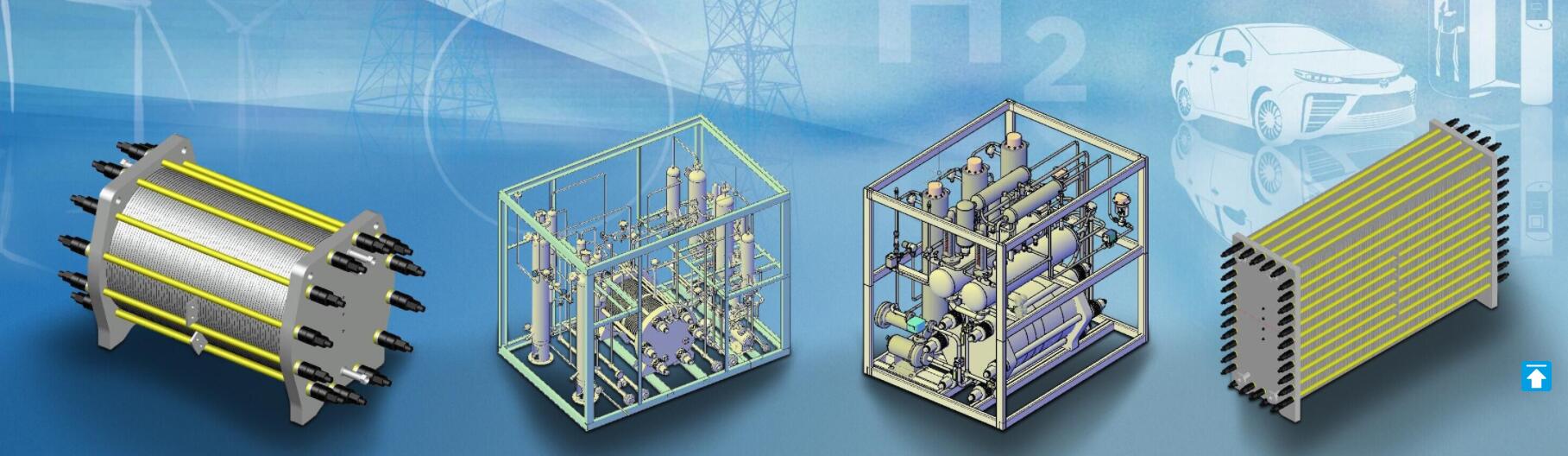

Zhongxinda hydrogen energy can develop container type hydrogen production equipment, skid mounted hydrogen production equipment and cabinet type hydrogen production equipment according to different site conditions and on the basis of traditional hydrogen production equipment. We can provide customized design of hydrogen production equipment to optimize and integrate existing plant facilities

|

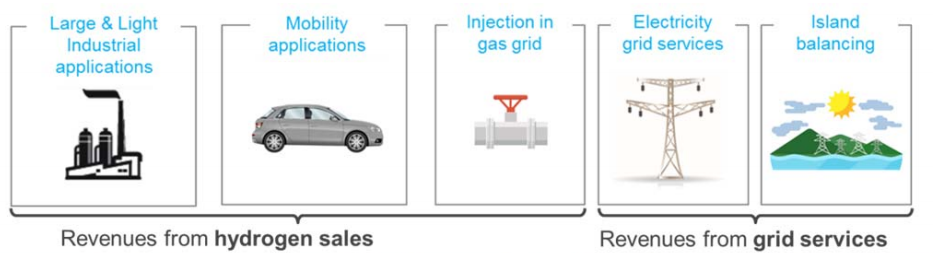

Application Energy Fields |

|

We have accumulated mature technologies in various application scenarios,

such as renewable energy, hydrogen production and storage reuse, fixed/skid-mounted hydrogenation stations,

by-product hydrogen exhaust hydrogen preparation, standby/emergency hydrogen fuel cell hydrogenation,

peak and frequency regulation in thermal power plants and dark green hydrogen microgrid.

We can provide hydrogen production, hydrogen storage and other hydrogen industry chain solutions

X

X