CWFL-1500 water chiller developed by S&A Teyu is made especially for fiber laser applications up to 1.5KW. This industrial water chiller is a temperature control device featuring two independent refrigeration circuits in one package. Therefore, separate cooling from just ONE chiller can be provided for the fiber laser and the laser head, saving considerable space and cost at the same time.

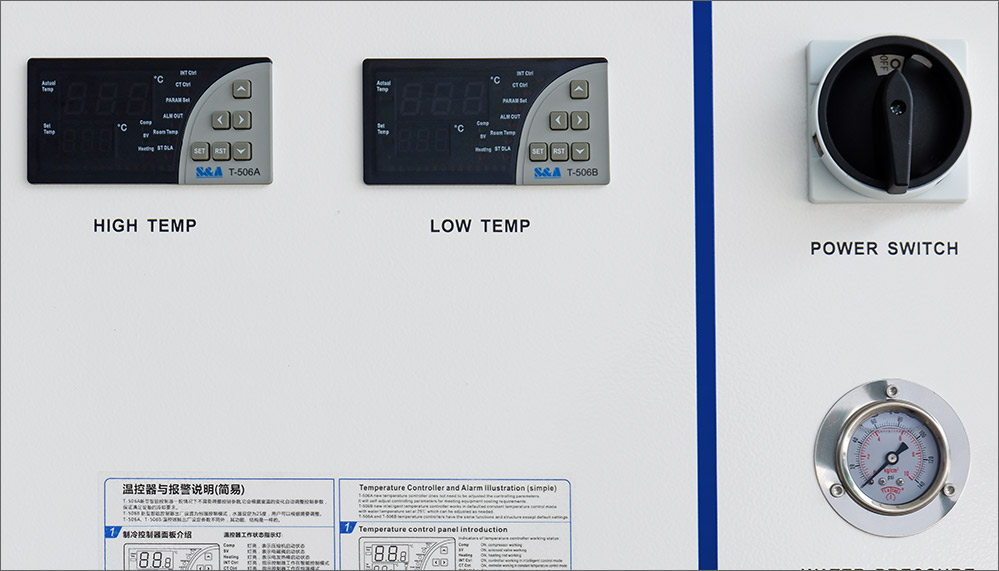

Two digital temperature controllers of the chiller are designed with built-in alarms so that your fiber laser machine can always be well protected against circulation problems or overheating. This laser water chiller is also designed with easy-to-read level check, caster wheels for easy mobility, high performance cooling fan and intelligent temperature control function which suggests water temperature can adjust itself automatically as the ambient temperature changes.

The warranty period is 2 years.

Features

1. Dual channel design for cooling fiber laser and the laser head, no need of a two-chiller solution;

Specification

Note:

1. The working current can be different under different working conditions; The above information is for reference only. Please subject to the actual delivered product;

2. Clean, pure, impurity free water should be used. The ideal one could be purified water, clean distilled water, deionised water, etc.;

3. Change out the water periodically (every 3 months is suggested or depending on the actual working environment);

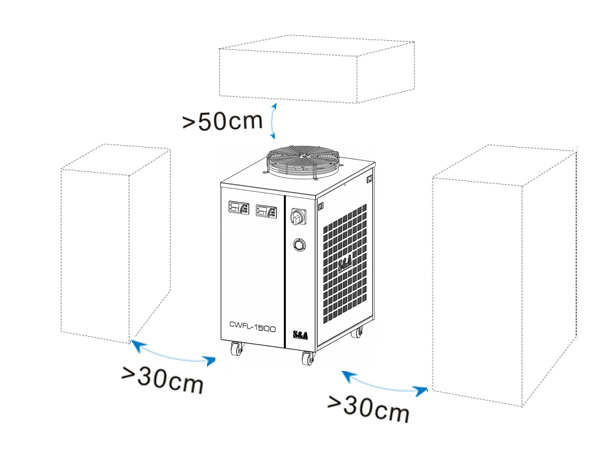

4. Location of the chiller should be well ventilated environment. There must be at least 50cm from the obstacles to the air outlet which is on the top of the chiller and should leave at least 30cm between obstacles and the air inlets which are on the side casing of the chiller.

PRODUCT INTRODUCTION

User-friendly temperature controllers for easy operation

Equipped with drain port and universal wheels

Dual inlet and dual outlet port made of stainless steel to prevent potential corrosion or water leakage

Water level check lets you know when it’s time to refill the tank

Cooling fan of famous brand installed.

Alarm description

E7 - water flow alarm input

CHILLER APPLICATION

WAREHOUSE

X

X