D-600P Automatic SMT Splicing Machine

D-600P Automatic Splicing Machine is designed for the automatic production line of SMT placement

machine. For paper tape and plastic tape with same specification, it can realize automatic correction

and splicing of two rolls of tapes with a width of 8mm. In the process of splicing, the equipment can

automatically realize accurate cutting and splicing, and automatically connect the head and tail of

two rolls of tapes by high adhesion film, so as to realize continuous production.

FEATURES FOR THE AUTOMATIC TAPE SPLICING MACHINE

● Compact Size Automatic SMT splicing Machine

● Dedicated 8mm carrier tape splicing

● Paper and plastic (embossed) tapes applicable

● Applicable carrier tape thickness : 0.25 - 2.5mm (carrier material dependent)

● Continuous operation for up to 16 hours once fully charged

● Up to 98% FPY

● Bluetooth and Wi-Fi connectivity to the factory MES

● One roll of splice tape contains 1500 pcs, ideal for continuous operation

● Optional label printer to facilitate material management

● Lightweight design for ease of use

● Power-assisted (motor powered) wheels to facilitate movement on the shop floor

TECHNICAL SPECIFICATIONS

|

Facilities Requirements |

Machine Dimension (mm) |

470(W) × 590(D) × 1145(H) |

|

Weight (kg) |

65 |

|

|

Safety |

Fully enclosed design with safety interlock switches to protect operator |

|

|

Conveyor |

Component Height (mm) |

955 |

|

Power Supply |

Power Source |

60Ah Battery |

|

Operation Time (when fully charged) |

12-16h |

|

|

Charging Voltage |

24V DC |

|

|

Power |

100W |

|

|

Motion System |

Repeatability (mm) |

0.1 |

|

Positioning accuracy of splicing tape (mm) |

±0.2 |

|

|

Carrier Tape |

Width(mm) |

8 |

|

Minimum Length for Splicing(mm) |

140 |

|

|

Component Reel |

Motorized Winder |

Standard Configuration |

|

Reel Size (mm) |

≤φ380 (consult Youngpool for special requirements) |

|

|

Splicing Rate |

Cycle Time (sec) |

≤7.2S (not including loading time) |

|

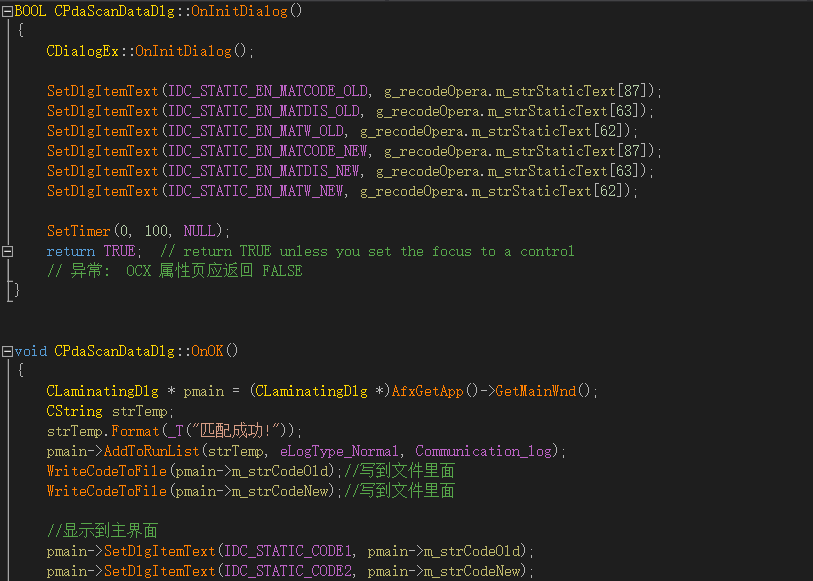

Software and Programming |

Control |

Computer Control |

|

Operating System |

Windows Interface |

|

|

Communication with MES |

Customizable |

|

|

Available Information |

Barcode Information, Battery Level, Alarms, Parameter Settings, Splicing Records |

|

|

Options and Accessories |

Power-assisted Wheels |

Available as Option |

|

Splice Clips / Shims |

Available as Option |

|

|

Label Printer |

Available as Option |

|

|

Barcode Scanner |

Standard Configuration |

|

|

Manual cutter for pre-cut |

Standard Configuration |

|

|

Extension Port |

USB2.0 |

Standard Configuration |

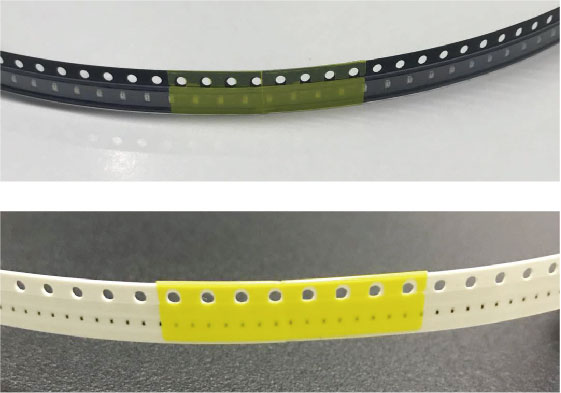

ILLUSTRATIONS OF AUTOMATIC SPLICING SYSTEM

[Barcode validation]

[Empty-pocket detection using vision inspection]

[Connecting effect display]

SPLICING MACHINE DIMENSIONS

● Published in July 2021 , All Rights Reserved

● All specifications are subject to change as a result of technical developments or advances. For questions on our products, please contact Youngpool Technonlogy (information@youngpool.com) or our local representative(s)

X

X