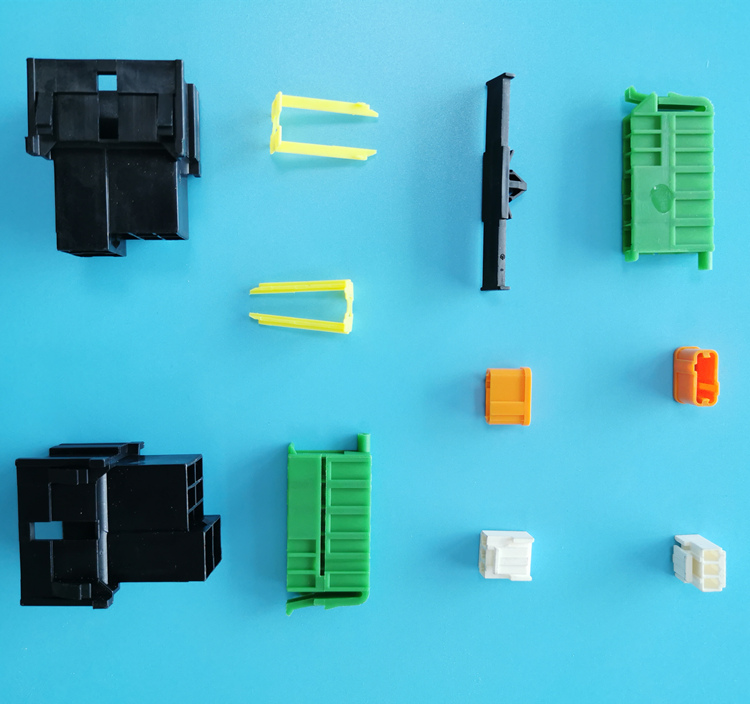

Working principle of plastic injection moulding part vision counting machine

High speed CCD camera scans objects that fall from vibrating chutes to obtain full projection images through optimized algorithm,machine will count number of falling objects so as to realize the batch counting and packaging.

Advantage of plastic injection moulding part vision counting machine

Technical data

|

Model |

VC193-2 |

|

Dimension |

1120*650*1100mm |

|

Accuracy |

99.99%,no negative deviation |

|

Material Dimension |

Ø3-30mm |

|

Production Efficiency |

Ø10mm,200pcs/bag,7-8bag/min |

|

Power Supply |

1.0KW |

|

Weight |

200KG |

|

Power Consumption |

AC220V,50HZ |

|

Bleed Pressure |

0.6-0.8MPa |

Notes: production capacity will vary for different particle size and way of packaging.

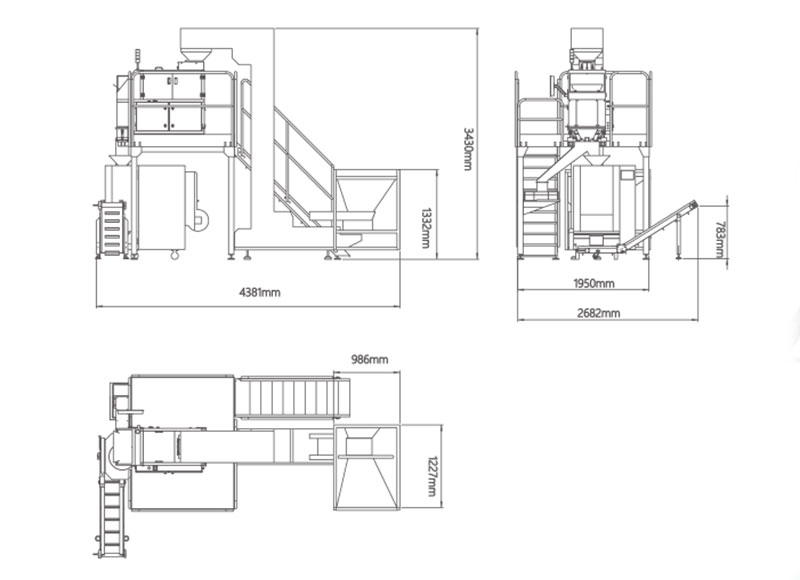

VC193+vertical packaging

Customized lifting system + counting system + printing labeling system+ packaging system +product delivery

Available with multiposition bag packaging machine,vertical packaging machine,box/canned packaging line

Package Demo

Factory Show

X

X